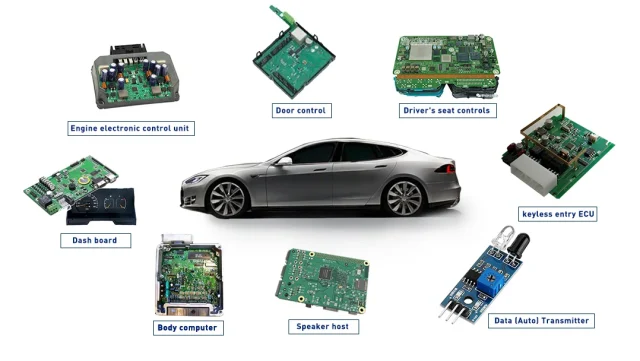

An Automotive IC Test PCB is a specialized printed circuit board used to validate automotive-grade integrated circuits, including power management ICs, microcontrollers, ADAS sensors, RF modules, and in-vehicle communication ICs. Automotive ICs must meet stringent reliability standards due to harsh operating environments, temperature extremes, and safety-critical applications.

These test PCBs play a critical role in Automated Test Equipment (ATE), load boards, and probe card systems, ensuring accurate IC characterization, functional verification, and production testing.

Key Design Challenges in Automotive IC Test PCBs

1. High Reliability under Harsh Conditions

Automotive IC test PCBs must maintain signal integrity, power stability, and thermal performance under extreme temperatures, vibration, and electrical noise.

2. Controlled Impedance and High-Speed Performance

Many automotive ICs operate at high frequencies, including automotive Ethernet, radar, and RF communication ICs. Controlled impedance routing ensures minimal signal reflection and accurate measurement.

3. Power Integrity and Multiple Voltage Domains

Automotive ICs often require multiple voltage rails. The PCB must provide stable power delivery, low-inductance planes, and decoupling networks to guarantee repeatable test results.

4. High-Density and Fine-Pitch Component Support

Modern automotive ICs feature high pin counts and fine-pitch packages, requiring multilayer stackups, microvias, and via-in-pad technologies to maintain routing density and signal integrity.

Structural Features of Automotive IC Test PCBs

-

Multilayer PCB stackups for separation of power, analog, and digital layers

-

Controlled impedance traces for high-speed signal routing

-

Low-loss PCB materials for RF and high-speed signals

-

Microvias, blind/buried vias, and via-in-pad designs to optimize routing

-

Thermal management features to handle automotive power IC testing

These features enable accurate, reliable, and repeatable testing of automotive ICs across prototypes, small batches, and mass production.

Applications of Automotive IC Test PCBs

Automotive IC test PCBs are commonly used for:

-

ADAS sensor IC testing (radar, lidar, cameras)

-

Powertrain and power management IC validation

-

Automotive Ethernet and in-vehicle networking IC testing

-

Automotive RF modules and 5G/V2X communication IC testing

-

Load boards and probe cards for ATE systems

Accurate test PCBs are critical for ensuring automotive IC reliability, safety, and performance.

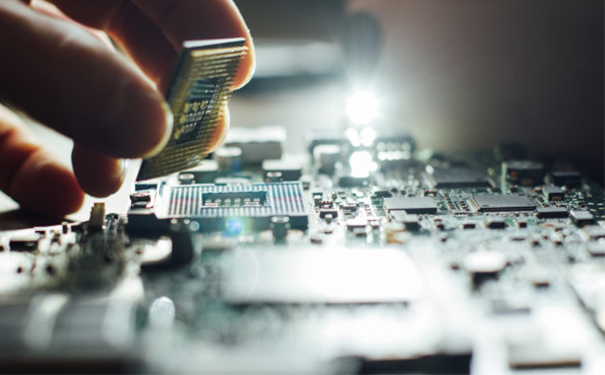

Manufacturing Requirements for Automotive IC Test PCBs

Producing high-quality automotive IC test PCBs requires:

-

Precise controlled impedance and trace tolerance

-

Advanced multilayer lamination and via processing

-

Low-loss and thermally stable PCB materials

-

Electrical testing and verification for signal integrity

-

Support for prototype, small batch, and high-volume production

A reliable manufacturer ensures consistent performance, long-term reliability, and compliance with automotive industry standards.

Conclusion

An Automotive IC Test PCB is essential for validating and qualifying automotive-grade integrated circuits. With controlled impedance, multilayer construction, microvia routing, and robust power integrity, these PCBs deliver highly reliable, accurate, and repeatable test results.

Partnering with an experienced automotive IC test PCB manufacturer ensures quality, compliance, and reliability, supporting automotive innovation from prototyping to mass production.