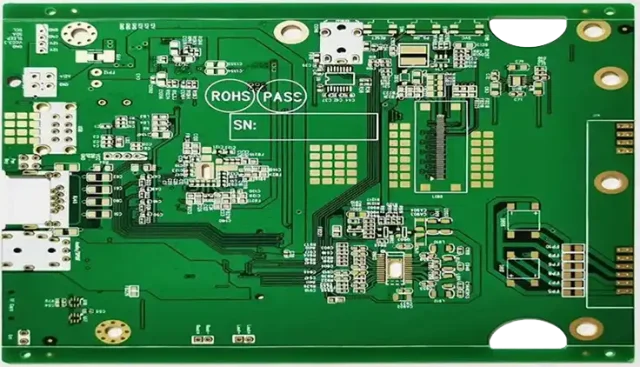

A High Speed IC Test PCB is a specialized semiconductor test PCB designed to validate integrated circuits operating at high data rates and fast edge speeds. These ICs are commonly used in 5G communication, high-speed computing, data centers, networking equipment, and automotive electronics. Accurate high-speed IC testing requires a precisely engineered PCB to maintain signal integrity and ensure reliable interaction with Automated Test Equipment (ATE).

As signal speeds continue to increase, even minor impedance mismatches, crosstalk, or losses can significantly impact measurement accuracy. A high-quality High Speed IC Test PCB plays a critical role in ensuring repeatable and accurate test results.

Key Design Requirements for High Speed IC Test PCBs

1. Controlled Impedance and Trace Consistency

High-speed interfaces demand precise controlled impedance, tight tolerance routing, and consistent dielectric thickness to prevent reflections and timing errors during testing.

2. Low-Loss Materials and Stackup Optimization

Advanced low-loss PCB materials reduce insertion loss and signal attenuation, enabling accurate measurement of high-frequency and high-speed signals.

3. Crosstalk and Noise Suppression

Careful layer stack design, spacing control, and reference plane integrity minimize crosstalk and electromagnetic interference in dense high-speed layouts.

4. High Pin Count and Fine-Pitch Routing

Modern high-speed ICs often feature high pin count packages and fine-pitch connections, requiring HDI technology, microvias, and multilayer PCB structures.

5. Stable Power Distribution Network (PDN)

An optimized power and ground network with effective decoupling ensures stable voltage delivery and reduces switching noise that can degrade signal integrity.

Applications of High Speed IC Test PCBs

High speed IC test PCBs are widely used in:

-

High-speed digital IC and processor testing

-

5G and high-speed communication IC validation

-

Networking and data center IC testing

-

Automotive high-speed interface testing

-

SerDes, PCIe, and memory interface validation

These applications require high signal fidelity, timing accuracy, and repeatable test performance.

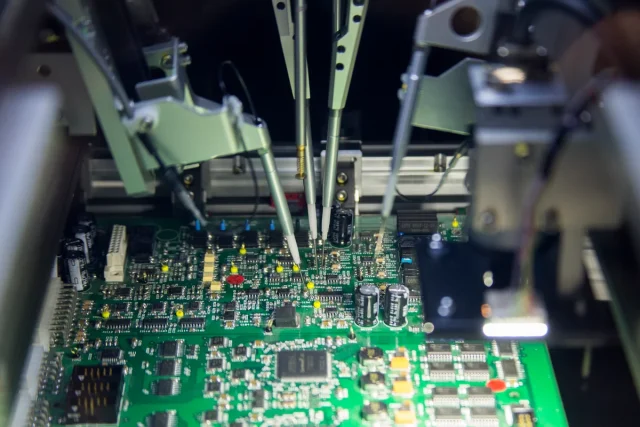

Manufacturing Capabilities for High Speed IC Test PCBs

Producing high-quality high speed test PCBs requires advanced manufacturing processes, including:

-

Multilayer and HDI PCB fabrication

-

Fine-line etching and microvia technology

-

Controlled impedance testing and verification

-

Tight tolerance lamination and drilling

-

Support for prototype, small batch, and volume production

Strict process control ensures consistency across multiple boards and test cycles.

Why High Speed IC Test PCB Quality Matters

Poorly manufactured high-speed test boards can result in:

-

Signal distortion and measurement errors

-

Unstable test results and reduced yield

-

Increased debugging time and development cost

-

Inconsistent interaction with ATE systems

A professionally engineered High Speed IC Test PCB ensures accurate measurements, stable testing environments, and faster product validation.

Conclusion

The High Speed IC Test PCB is essential for validating today’s high-performance integrated circuits. With precise impedance control, low-loss materials, and advanced HDI design, these boards deliver reliable and repeatable performance in demanding high-speed ATE environments.

Choosing an experienced semiconductor test PCB manufacturer enables faster validation cycles, improved test accuracy, and long-term reliability for high-speed IC testing.