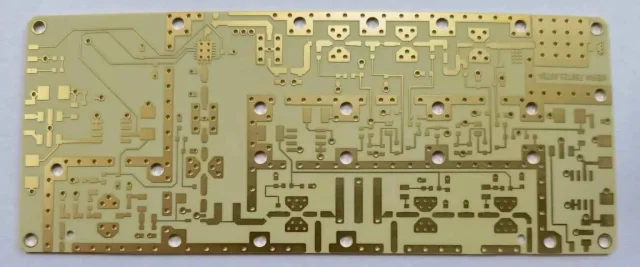

As RF and microwave systems continue to push into higher frequencies, material selection becomes a critical factor in circuit performance. The Duroid 6002 PCB is widely used in high-frequency designs where low loss, tight impedance control, and thermal stability are essential. Compared with standard FR-4, Duroid 6002 offers significantly improved electrical performance for demanding RF and microwave applications.

What Is a Duroid 6002 PCB?

A Duroid 6002 PCB is a high-frequency printed circuit board fabricated using Rogers RT/duroid® 6002 laminate. This material is designed specifically for RF and microwave circuits and features:

-

Low dielectric constant (Dk) for controlled impedance

-

Low dissipation factor (Df) for reduced signal loss

-

Excellent thermal and mechanical stability

These properties make Duroid 6002 ideal for precision RF designs.

Key Electrical Properties of Duroid 6002

Duroid 6002 is optimized for high-frequency signal transmission. Key characteristics include:

-

Stable dielectric constant across wide frequency ranges

-

Low dielectric loss for improved insertion loss

-

Minimal phase variation for consistent RF performance

These properties help ensure predictable circuit behavior.

Controlled Impedance Performance

Controlled impedance is essential in RF and microwave PCBs. A Duroid 6002 PCB enables:

-

Accurate transmission line modeling

-

Consistent trace geometry and impedance control

-

Reduced impedance variation over temperature

This improves signal integrity in high-speed RF paths.

Low Loss at RF and Microwave Frequencies

Signal loss increases rapidly at high frequencies. Duroid 6002 PCBs minimize loss by:

-

Using low-loss PTFE-based dielectric material

-

Reducing attenuation in long RF traces

-

Supporting high-Q circuit designs

Lower loss translates to higher system efficiency and sensitivity.

Thermal Stability and Reliability

Thermal performance is critical in RF systems. A Duroid 6002 PCB offers:

-

Low coefficient of thermal expansion (CTE)

-

Stable electrical properties over temperature changes

-

Improved reliability in harsh environments

This stability is essential for mission-critical applications.

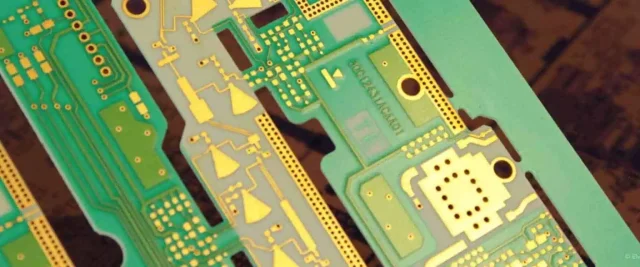

Hybrid Stackup Capability

Duroid 6002 is often combined with FR-4 in hybrid stackups. This approach allows:

-

Cost optimization for mixed-signal designs

-

RF performance where needed, digital performance elsewhere

-

Mechanical stability in multilayer constructions

Hybrid designs provide flexibility without sacrificing performance.

Manufacturing Considerations for Duroid 6002 PCBs

Fabricating Duroid 6002 PCBs requires specialized processes, including:

-

Controlled drilling and via preparation

-

Optimized lamination parameters

-

Careful copper surface treatment

Experienced manufacturing ensures consistent RF performance.

Typical Applications of Duroid 6002 PCBs

Duroid 6002 PCBs are widely used in:

-

RF front-end modules

-

Microwave amplifiers and filters

-

Radar and satellite communication systems

-

High-frequency test and measurement equipment

These applications demand low loss and high stability.

Choosing a Duroid 6002 PCB Manufacturing Partner

When selecting a Duroid 6002 PCB manufacturer, consider:

-

Experience with PTFE-based materials

-

Controlled impedance and RF testing capability

-

Hybrid stackup design support

-

Proven quality control processes

The right partner ensures optimal RF performance.

Conclusion

The Duroid 6002 PCB is a premium solution for RF and microwave applications requiring low loss, tight impedance control, and excellent thermal stability. By choosing the right materials, stackup, and manufacturing processes, Duroid 6002 PCBs deliver reliable high-frequency performance in demanding environments.

Partnering with an experienced Duroid 6002 PCB supplier is key to achieving consistent and high-quality RF designs.