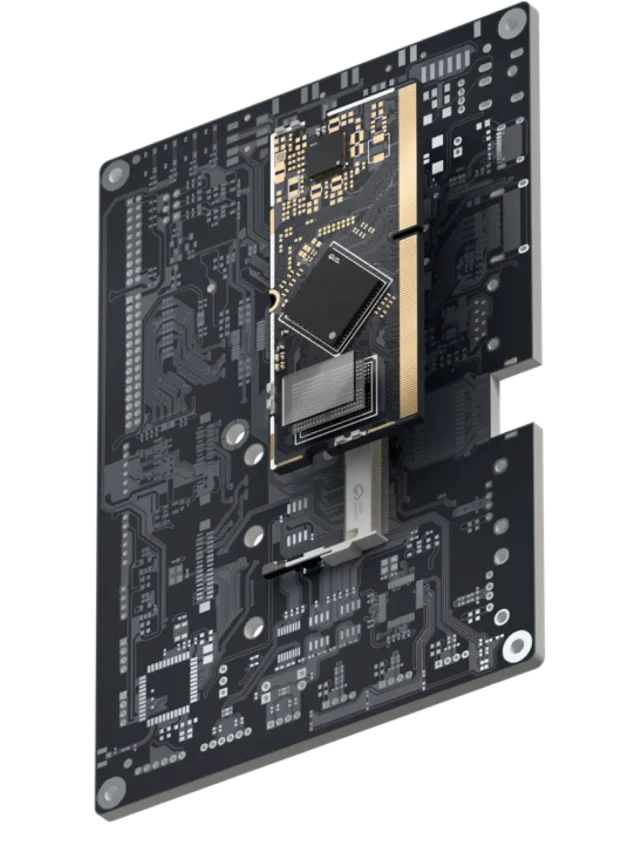

As electronic systems continue to integrate more functionality into smaller form factors, the number of signal, power, and ground connections continues to rise. The High Pin Count PCB is specifically engineered to manage thousands of interconnections while maintaining electrical integrity, mechanical reliability, and manufacturability.

A professionally designed High Pin Count PCB is essential for modern semiconductor test hardware, high-speed communication systems, and advanced computing platforms.

What Is a High Pin Count PCB?

A High Pin Count PCB is a printed circuit board designed to support devices or connectors with a very large number of I/O pins. These PCBs serve as the backbone for:

-

High-density IC packages

-

Semiconductor test interfaces

-

Advanced digital and mixed-signal systems

Unlike standard PCBs, high pin count boards prioritize routing efficiency and signal integrity under extreme density constraints.

Why High Pin Count PCB Design Is Challenging

Increasing pin count introduces multiple design challenges:

-

Limited routing channels between pads

-

Higher risk of crosstalk and signal coupling

-

Complex power and ground distribution

-

Tight mechanical tolerance requirements

A well-engineered High Pin Count PCB addresses these challenges through advanced layout and stackup strategies.

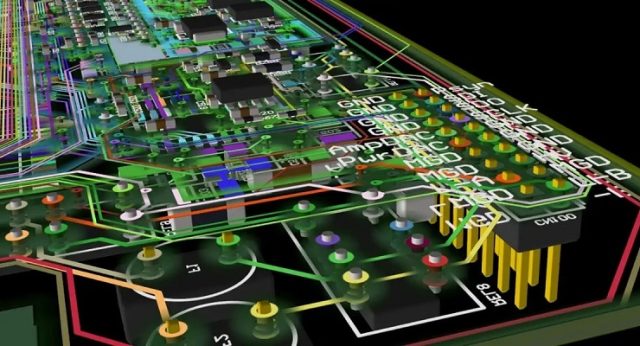

Advanced Routing and HDI Technology

Most High Pin Count PCBs rely on HDI techniques, including:

-

Microvias and via-in-pad structures

-

Fine line and space routing

-

Sequential lamination for multilayer designs

HDI technology enables efficient signal breakout and routing from dense pin fields.

Signal Integrity in High Pin Count PCBs

As pin density increases, maintaining signal integrity becomes critical. Effective high pin count PCB designs incorporate:

-

Controlled impedance routing

-

Length matching for high-speed signals

-

Dedicated reference planes for clean return paths

These measures help reduce crosstalk, reflections, and timing skew.

Power Integrity and Ground Management

High pin count systems often include multiple voltage domains. A robust High Pin Count PCB design ensures:

-

Low-impedance power distribution networks

-

Sufficient ground plane coverage

-

Proper decoupling capacitor placement

Stable power delivery supports accurate signal switching and system reliability.

Mechanical Reliability and Structural Stability

Dense interconnections can increase mechanical stress. To ensure long-term reliability, High Pin Count PCBs must feature:

-

Balanced multilayer stackups

-

Excellent flatness and coplanarity

-

Reinforced high-stress areas

Mechanical stability is especially important in test and high-cycle applications.

Materials and Stackup Selection

Material choice plays a significant role in high pin count PCB performance:

-

High-Tg FR-4 for structural stability

-

Low-loss laminates for high-speed signals

-

Hybrid stackups for mixed-signal environments

Careful material selection ensures consistent electrical behavior.

Manufacturing Precision and Yield Control

High pin count PCBs require strict manufacturing control:

-

Accurate drilling and via registration

-

Consistent copper thickness and etching

-

Thorough electrical testing

Manufacturing precision directly affects yield and long-term reliability.

Typical Applications of High Pin Count PCBs

High Pin Count PCBs are widely used in:

-

Semiconductor test hardware (ATE, load boards, sockets)

-

High-speed networking and data center equipment

-

Advanced computing and AI systems

-

Automotive and industrial electronics

These applications demand dense, reliable interconnections.

Choosing a High Pin Count PCB Manufacturing Partner

When selecting a High Pin Count PCB manufacturer, consider:

-

Experience with HDI and multilayer designs

-

Capability for controlled impedance and high-speed routing

-

Strong quality management and process consistency

-

Engineering support for complex layouts

A trusted partner helps reduce risk and accelerate development.

Conclusion

The High Pin Count PCB is a key enabler of advanced electronic systems, allowing dense interconnections without compromising electrical performance or reliability. By combining HDI technology, signal and power integrity optimization, and precise manufacturing processes, high pin count PCBs support the next generation of high-performance electronics.

Partnering with an experienced High Pin Count PCB supplier ensures successful implementation from prototype to production.