5G millimeter-wave technology is driving a new generation of ultra-fast wireless communication. Operating in frequency bands such as 24 GHz, 28 GHz, and 39 GHz, 5G mmWave systems require extremely strict control over signal loss, impedance accuracy, and manufacturing tolerances. At the heart of these systems lies the 5G mmWave PCB, a specialized high frequency PCB designed specifically for millimeter-wave signal transmission.

A professionally engineered 5G mmWave PCB directly determines system performance, antenna efficiency, and long-term reliability in demanding 5G applications.

What Defines a 5G mmWave PCB?

A 5G mmWave PCB is a type of millimeter wave PCB optimized for ultra-short wavelengths and very high signal frequencies. Compared with conventional RF PCBs, mmWave PCBs must meet much tighter electrical and mechanical requirements.

Key characteristics of a high-quality 5G mmWave PCB include:

-

Ultra-low dielectric loss to reduce signal attenuation

-

Precise controlled impedance for stable high-speed transmission

-

Excellent dielectric thickness consistency

-

High dimensional accuracy across the entire board

These requirements make 5G mmWave PCB manufacturing significantly more complex than standard high-frequency PCB production.

Material Selection: The Foundation of 5G mmWave PCB Performance

Material choice is the most critical factor in 5G mmWave PCB design. Commonly used low loss PCB materials include:

-

Rogers RO4003C and RO4350B

-

RT/duroid® 5880 and Duroid 6002

-

Taconic RF-35, TLY, and other PTFE-based laminates

These materials provide low Dk variation, extremely low dissipation factor, and stable performance at millimeter-wave frequencies. In many designs, hybrid stackups combining FR-4 and RF materials are used to balance electrical performance and cost.

Signal Integrity Challenges in Millimeter-Wave PCB Design

At mmWave frequencies, even minimal layout imperfections can lead to major performance degradation. Poorly designed 5G mmWave PCBs may suffer from:

-

Excessive insertion loss

-

Phase instability

-

Impedance discontinuities

-

Increased crosstalk and radiation loss

To overcome these challenges, millimeter wave PCB design typically includes:

-

Short, straight RF trace routing

-

Smooth impedance transitions

-

Optimized via structures and back-drilling

-

Continuous and well-referenced ground planes

Every micron matters in high-frequency PCB layout at mmWave bands.

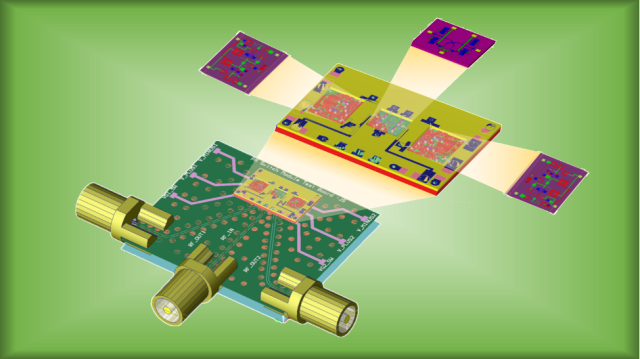

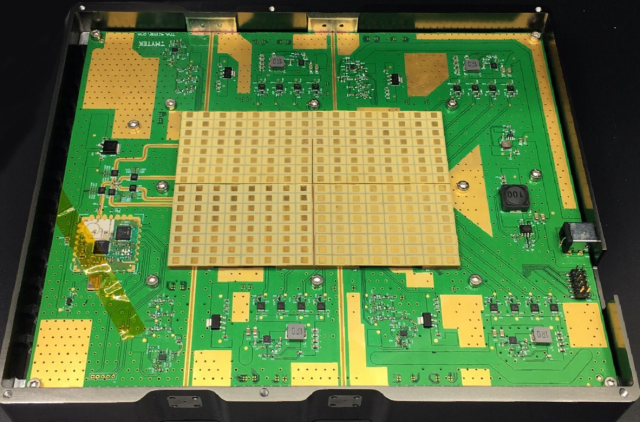

Antenna Integration on 5G mmWave PCBs

Many modern 5G mmWave PCBs integrate antennas directly onto the PCB or support antenna-in-package (AiP) solutions. PCB quality directly affects:

-

Antenna radiation efficiency

-

Beamforming accuracy

-

Phase alignment across antenna arrays

Precise dielectric control and consistent manufacturing processes are essential for stable antenna performance in 5G mmWave systems.

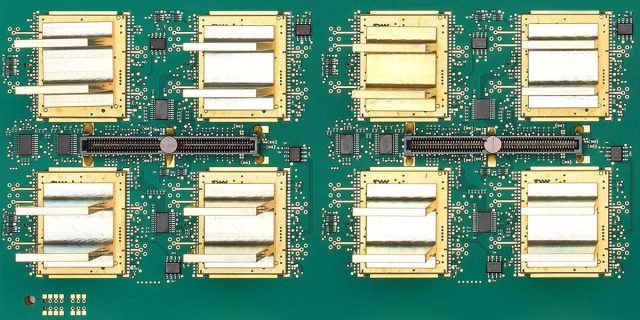

Manufacturing Precision for 5G mmWave PCBs

Producing a reliable 5G mmWave PCB requires advanced manufacturing capabilities far beyond standard PCB fabrication. Key process controls include:

-

Tight line width and spacing tolerances

-

Accurate laminate thickness control

-

Specialized PTFE drilling and plating techniques

-

High-precision impedance testing

An experienced mmWave PCB manufacturer ensures consistent RF performance from prototype to mass production.

Applications of 5G mmWave PCBs

High-performance 5G mmWave PCBs are widely used in:

-

5G base stations and small cells

-

mmWave user equipment (UE)

-

RF front-end and beamforming modules

-

Automotive, industrial, and fixed wireless access systems

Each application demands stable performance under high-frequency and high-density conditions.

Choosing the Right 5G mmWave PCB Manufacturer

Selecting the right 5G mmWave PCB manufacturer is essential for project success. Key capabilities to look for include:

-

Proven experience with millimeter wave PCB manufacturing

-

Expertise in Rogers, Duroid, and PTFE materials

-

Controlled impedance and RF test capability

-

Support for quick-turn prototypes and volume production

A reliable supplier ensures higher yield, lower risk, and faster time-to-market.

Conclusion

The 5G mmWave PCB is a core enabler of next-generation wireless technology. By combining low-loss materials, precision RF design, and tightly controlled manufacturing processes, high-quality millimeter wave PCBs deliver the performance and reliability required for modern 5G systems.

Partnering with an experienced 5G mmWave PCB supplier ensures stable signal integrity, consistent antenna performance, and long-term system reliability at millimeter-wave frequencies.