As operating frequencies and data rates continue to rise, signal loss becomes a critical concern in electronic system design. Choosing a reliable low loss high frequency PCB supplier is essential to ensure stable signal transmission, accurate impedance control, and consistent product performance.

Low loss high frequency PCBs are widely used in RF, microwave, 5G, and high-speed communication systems where even small losses can significantly impact system efficiency.

What Is a Low Loss High Frequency PCB?

A low loss high frequency PCB is manufactured using specialized laminate materials designed to minimize dielectric and conductor loss at high frequencies. Compared with standard FR-4, these materials offer:

-

Lower dissipation factor (Df)

-

Stable dielectric constant (Dk)

-

Reduced signal attenuation

-

Improved phase and impedance stability

These characteristics are critical for high-frequency and RF applications.

Key Materials Offered by a Low Loss High Frequency PCB Supplier

A professional low loss high frequency PCB supplier supports a wide range of advanced materials, including:

-

Rogers RO4003 / RO4350 series

-

Taconic RF and TLY series

-

PTFE-based laminates

-

Hybrid RF + FR-4 stackups

Proper material selection directly impacts signal loss and manufacturing cost.

Why Choose a Specialized Low Loss High Frequency PCB Supplier?

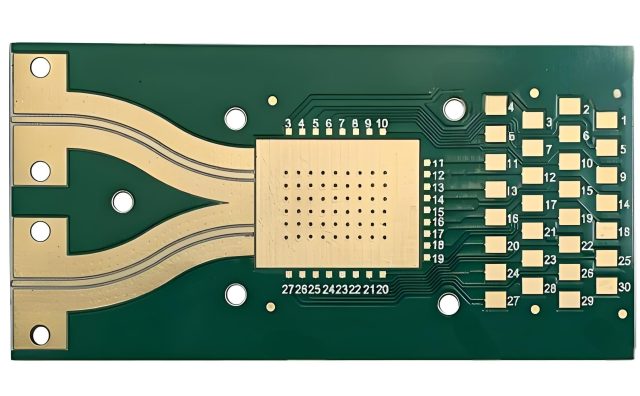

Ultra-Low Signal Loss Control

Low loss materials and optimized fabrication processes reduce insertion loss and improve RF efficiency.

Precise Impedance Control

A qualified supplier ensures controlled impedance within ±5% or tighter, which is critical for RF and high-speed designs.

Advanced Manufacturing Capability

High-frequency PCBs require tighter tolerances, smoother copper surfaces, and accurate layer registration.

Consistent Quality and Reliability

Experienced suppliers implement strict quality control to ensure stable performance across production batches.

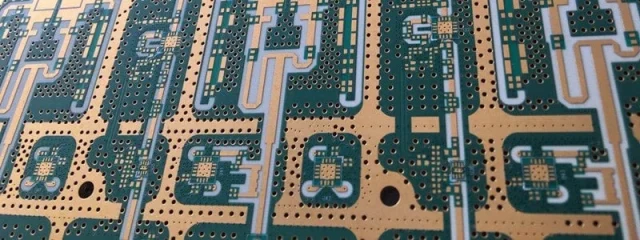

Manufacturing Processes for Low Loss High Frequency PCBs

A professional low loss high frequency PCB supplier provides:

-

Precision etching for fine-line RF traces

-

Copper roughness optimization

-

Accurate lamination thickness control

-

Controlled impedance fabrication

-

TDR impedance testing and electrical inspection

These processes minimize both dielectric and conductor loss.

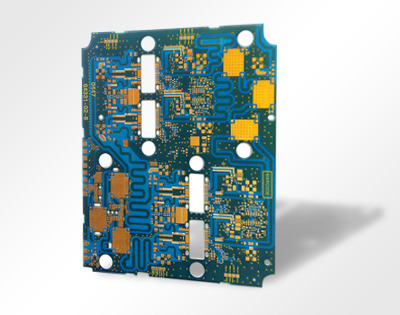

Applications of Low Loss High Frequency PCBs

Low loss high frequency PCBs are widely used in:

-

RF front-end modules

-

Microwave communication systems

-

5G base stations and antennas

-

mmWave and radar applications

-

High-speed networking equipment

These applications demand low attenuation and stable signal integrity.

Prototype to Mass Production Support

A reliable low loss high frequency PCB supplier supports:

-

Quick-turn PCB prototypes

-

Small batch and pilot production

-

Scalable mass production

-

Engineering support and DFM optimization

This ensures a smooth transition from development to volume manufacturing.

How to Choose the Right Low Loss High Frequency PCB Supplier

When selecting a low loss high frequency PCB supplier, evaluate:

-

Experience with RF and microwave materials

-

Impedance control and RF testing capability

-

Manufacturing equipment and process control

-

Quality certifications and inspection standards

-

On-time delivery and technical support

The right supplier reduces risk and ensures long-term success.

Conclusion

Choosing a professional low loss high frequency PCB supplier is critical for achieving reliable RF and high-speed performance. With advanced materials, precise impedance control, and RF-focused manufacturing processes, low loss high frequency PCBs deliver stable signal transmission and high system efficiency.

Partnering with an experienced supplier ensures your high-frequency PCB projects meet performance, quality, and scalability requirements.