In 5G communication systems, antenna performance directly impacts signal coverage, efficiency, and data throughput. Selecting the right PCB material is critical, especially for sub-6 GHz and high-speed RF antenna designs. RO4003 PCB for 5G antenna applications is widely adopted due to its low loss, stable dielectric properties, and excellent manufacturability.

Compared with conventional FR-4 materials, RO4003 PCB delivers more predictable RF performance, making it an ideal choice for professional 5G antenna designs.

Overview of RO4003 PCB Material

RO4003 PCB is based on Rogers RO4003C laminate, a hydrocarbon ceramic composite designed for RF and microwave circuits. Key electrical characteristics include:

-

Dielectric constant (Dk) around 3.55

-

Low dissipation factor (Df ≈ 0.0027 @ 10 GHz)

-

Excellent thermal stability and low moisture absorption

-

Consistent performance across temperature and frequency

These properties make RO4003 PCB for 5G antenna designs highly reliable and repeatable.

Benefits of RO4003 PCB for 5G Antenna Design

Low Dielectric Loss for Improved Efficiency

Low loss characteristics reduce RF signal attenuation, helping 5G antennas achieve higher radiation efficiency and better gain.

Stable Impedance Control

A stable dielectric constant allows accurate impedance control, which is essential for antenna matching and minimizing reflection loss.

Predictable RF Behavior

RO4003 PCB ensures consistent antenna resonance and bandwidth performance, even under varying environmental conditions.

Cost-Effective RF Manufacturing

Compared with PTFE-based laminates, RO4003 PCB is easier to fabricate, resulting in lower production cost and higher yield.

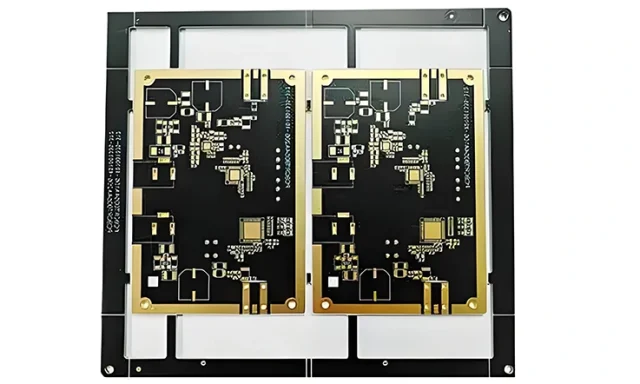

Controlled Impedance Requirements for RO4003 PCB

Manufacturing RO4003 PCB for 5G antenna applications requires strict impedance control. Professional PCB factories implement:

-

Precise stackup design and impedance simulation

-

Tight tolerance control of dielectric thickness and copper width

-

Controlled impedance fabrication (typically ±5% or better)

-

TDR testing to verify RF trace impedance

These processes ensure stable antenna matching and RF consistency.

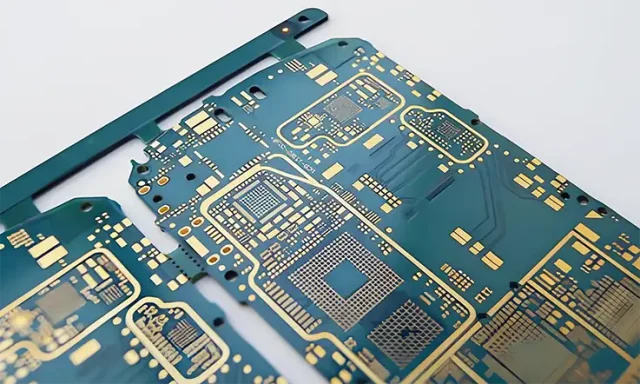

Common RO4003 PCB Stackups for 5G Antennas

Typical RO4003 PCB stackup configurations include:

-

Single-layer and double-layer antenna PCBs

-

Multilayer RO4003 PCBs with dedicated ground planes

-

Hybrid stackups combining RO4003 and FR-4 to balance performance and cost

Hybrid RO4003 + FR-4 designs are commonly used in compact 5G antenna modules.

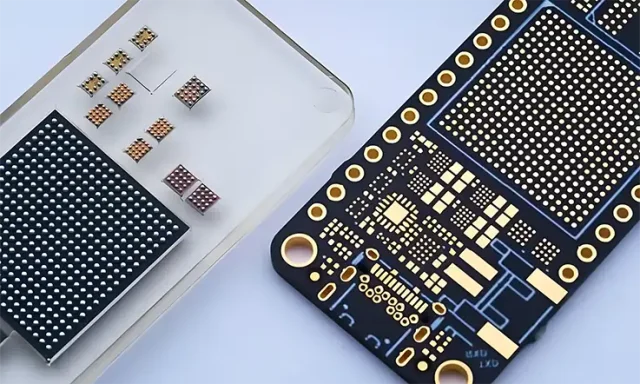

Manufacturing Considerations for RO4003 PCB for 5G Antenna

Producing high-quality RO4003 PCB for 5G antenna applications involves specialized RF manufacturing control, including:

-

Fine-line etching for antenna geometry accuracy

-

Copper roughness optimization to reduce conductor loss

-

Precision drilling and reliable via metallization

-

AOI, electrical testing, and impedance verification

Experienced RF PCB manufacturers ensure consistency from prototype to mass production.

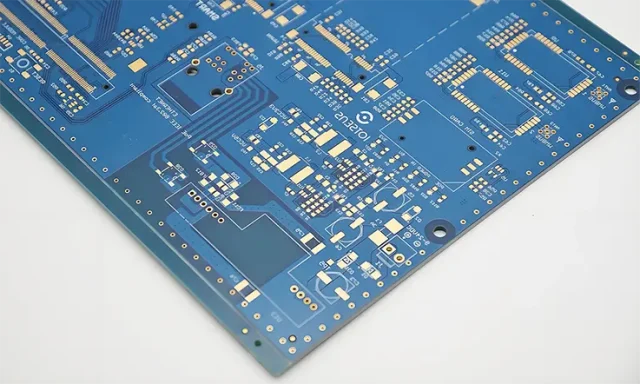

Typical Applications of RO4003 PCB in 5G Systems

RO4003 PCBs are widely used in:

-

Sub-6 GHz 5G antenna arrays

-

5G small cell and base station antennas

-

RF front-end antenna modules

-

Wireless communication and IoT antenna products

These applications demand low loss, stable impedance, and reliable long-term performance.

Selecting a Supplier for RO4003 PCB for 5G Antenna

When sourcing RO4003 PCB for 5G antenna, buyers should evaluate:

-

Experience with Rogers RO4003 materials

-

RF and impedance control capability

-

Support for prototypes and volume production

-

Engineering support and DFM optimization

A qualified supplier ensures stable antenna performance and scalable manufacturing.

Conclusion

RO4003 PCB for 5G antenna applications provides an excellent combination of low loss, stable dielectric properties, and cost-effective manufacturability. With proper stackup design and controlled impedance production, RO4003 PCBs deliver reliable RF performance for modern 5G antenna systems.

Partnering with an experienced RF PCB manufacturer ensures your RO4003 PCB antenna designs meet both technical and production requirements.