As RF and wireless technologies continue to evolve, the demand for stable, low-loss, and high-reliability PCBs has increased significantly. When engineers and procurement teams purchase RF PCBs, performance consistency, material quality, and manufacturing capability are critical factors that directly affect system reliability.

This article explains what to consider when purchasing RF PCBs and how professional RF PCB manufacturers support high-frequency applications.

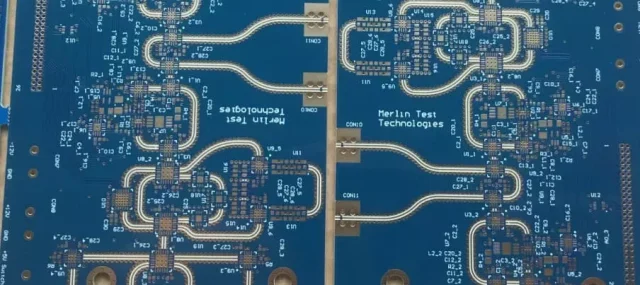

What Is an RF PCB?

An RF PCB is designed to handle radio frequency signals with minimal loss and distortion. Unlike standard PCBs, RF PCBs require:

-

Low dielectric loss (low Df)

-

Stable dielectric constant (Dk)

-

Controlled impedance structures

-

Precise manufacturing tolerances

These characteristics make RF PCBs essential for high-frequency and wireless applications.

Why Material Selection Matters When You Purchase RF PCB

Material selection is the foundation of RF performance. When you purchase RF PCBs, commonly used materials include:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

PTFE-based substrates for microwave and mmWave designs

-

Taconic RF materials such as RF-35

-

Hybrid stackups combining RF materials with FR-4

These materials provide lower signal loss and more stable RF performance than standard FR-4.

Controlled Impedance: A Key Requirement for RF PCBs

Accurate impedance control is essential when you purchase RF PCBs for high-frequency signal transmission.

Professional RF PCB manufacturers offer:

-

Stack-up simulation and impedance modeling

-

Tight control of trace width and dielectric thickness

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance testing and reporting

This ensures minimal signal reflection and consistent RF performance.

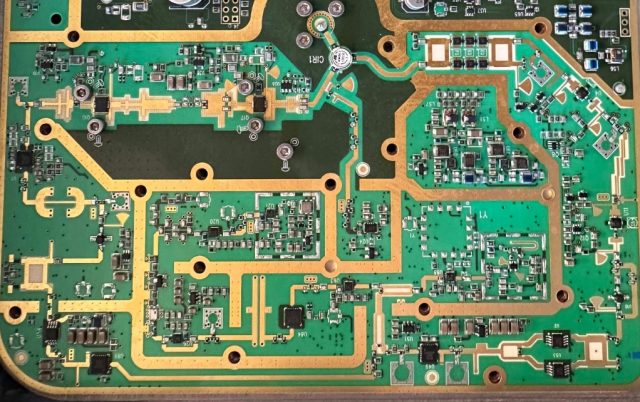

Manufacturing Quality and RF PCB Reliability

When purchasing RF PCBs, manufacturing quality plays a decisive role. Reliable RF PCB suppliers focus on:

-

Precision lamination and etching

-

Copper roughness control to reduce conductor loss

-

AOI, X-ray inspection, and electrical testing

-

Stable process control from prototype to mass production

These processes ensure consistent quality and long-term reliability.

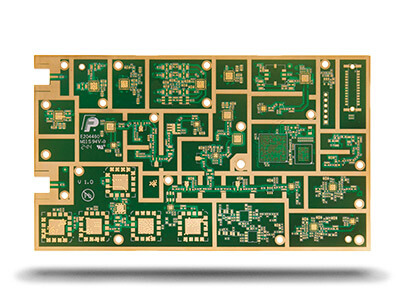

Applications That Require RF PCBs

RF PCBs are widely used in:

-

RF front-end and antenna modules

-

5G and wireless communication systems

-

Microwave and mmWave circuits

-

Automotive radar and sensing systems

-

IoT and high-speed wireless devices

Each application requires low loss, stable impedance, and high manufacturing precision.

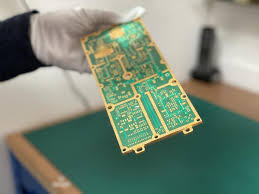

How to Choose the Right Supplier When You Purchase RF PCB

When selecting a supplier to purchase RF PCBs, consider:

-

Experience in RF and high-frequency PCB manufacturing

-

Support for Rogers, PTFE, and hybrid materials

-

Impedance testing and RF quality control capability

-

Engineering support and DFM feedback

-

Flexible production from prototype to volume

The right supplier reduces risk and shortens development cycles.

Conclusion

To ensure reliable performance in high-frequency and wireless systems, it is essential to purchase RF PCBs from an experienced and professional manufacturer. With advanced RF materials, precise impedance control, and strict quality assurance, professional RF PCB suppliers deliver solutions that meet the demands of modern RF applications.

By choosing the right partner when you purchase RF PCBs, you can achieve consistent performance, faster validation, and scalable production for your RF products.