High-speed RF front-end modules operate at increasingly higher frequencies, where PCB material choice directly impacts signal loss, impedance stability, and overall system performance. When engineers and procurement teams buy high frequency PCBs, selecting the right materials—such as Rogers laminates, PTFE substrates, and hybrid stackups—is critical for achieving reliable RF performance.

This article explains how to buy high frequency PCBs for RF front-end modules, with a focus on material options, manufacturing considerations, and performance optimization.

Why Material Selection Matters When Buying High Frequency PCBs

When you buy high frequency PCBs, material properties such as dielectric constant (Dk), dissipation factor (Df), and thermal stability directly affect RF signal integrity.

High-speed RF front-end modules require:

-

Low insertion loss

-

Stable impedance across frequency

-

Minimal phase variation

-

Reliable performance under thermal stress

Standard FR-4 materials are often insufficient for these requirements, making specialized RF materials essential.

Buying High Frequency PCBs with Rogers Materials

Rogers PCBs are widely used in RF front-end modules due to their proven high-frequency performance.

Common Rogers materials include:

-

RO4003 / RO4350 for cost-effective high-frequency designs

-

RO3003 / RO3006 for microwave and mmWave applications

Advantages when buying Rogers high frequency PCBs:

-

Low Df for reduced signal loss

-

Stable Dk over frequency and temperature

-

Excellent impedance control consistency

-

Strong manufacturability for RF designs

Rogers PCBs are ideal for sub-6 GHz and microwave RF front-end modules.

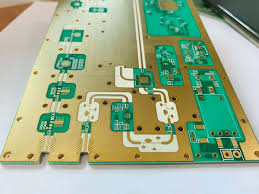

Buying High Frequency PCBs with PTFE Materials

For higher frequencies and ultra-low-loss requirements, many designers choose PTFE-based high frequency PCBs.

Key benefits of PTFE PCBs:

-

Extremely low dielectric loss

-

Excellent performance at microwave and mmWave frequencies

-

Superior phase stability for high-speed RF signals

When buying PTFE high frequency PCBs, it is important to work with an experienced manufacturer due to the specialized processing required for PTFE materials.

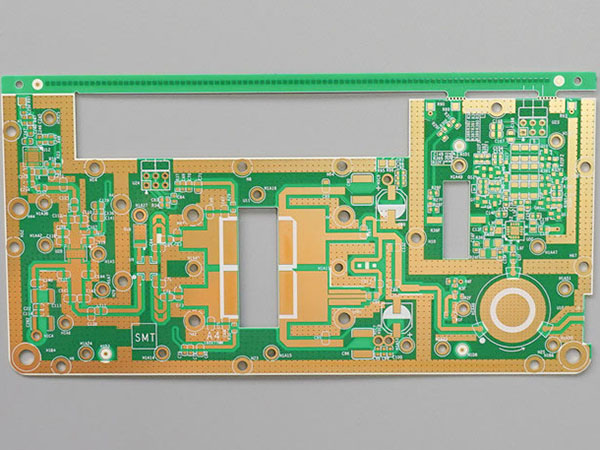

Hybrid Stackups: Optimizing Cost and Performance

A hybrid stackup combines RF materials (Rogers or PTFE) with FR-4 in the same PCB.

When you buy high frequency PCBs with hybrid stackups, you benefit from:

-

Low-loss RF layers for critical signal paths

-

FR-4 layers for digital, control, and power circuits

-

Reduced overall PCB cost

-

Flexible design optimization

Hybrid stackups are widely used in high-speed RF front-end modules where both RF and digital circuits coexist.

Impedance Control for RF Front-End PCBs

Accurate impedance control is essential when buying high frequency PCBs for RF front-end modules.

Professional manufacturers provide:

-

Stack-up simulation and impedance modeling

-

Tight line width and spacing control

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance testing and reporting

Proper impedance control minimizes reflection loss and ensures stable RF front-end performance.

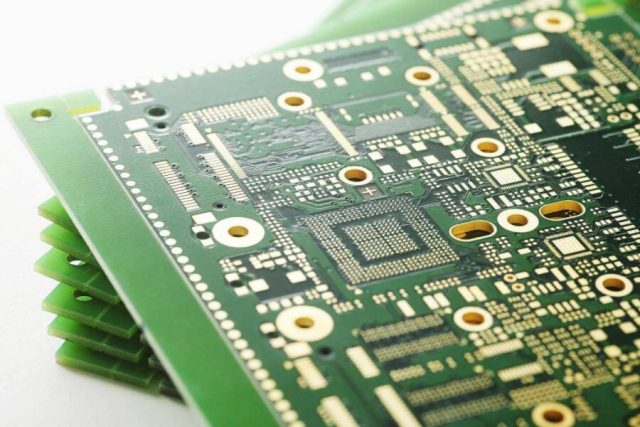

Manufacturing Quality and Testing Considerations

When you buy high frequency PCBs, manufacturing quality is just as important as material selection.

Key manufacturing and testing factors include:

-

Copper surface roughness control to reduce conductor loss

-

Precision lamination and etching

-

Electrical testing and RF inspection

-

Consistent process control across batches

These factors ensure reliable performance in high-speed RF front-end modules.

Applications of High Frequency PCBs in RF Front-End Modules

High frequency PCBs using Rogers, PTFE, and hybrid stackups are widely used in:

-

RF front-end and antenna modules

-

5G and wireless communication systems

-

Microwave and mmWave transceivers

-

Automotive radar and sensing systems

-

High-speed data transmission equipment

These applications demand low loss, stable impedance, and high manufacturing reliability.

How to Choose the Right Supplier When Buying High Frequency PCBs

When selecting a supplier to buy high frequency PCBs, consider:

-

Experience with Rogers, PTFE, and hybrid stackups

-

Impedance control and TDR testing capability

-

RF-focused manufacturing expertise

-

Prototype and volume production support

-

Engineering communication and DFM feedback

The right supplier reduces risk and ensures long-term success.

Conclusion

To achieve reliable performance in high-speed RF front-end modules, it is essential to buy high frequency PCBs using the right materials and manufacturing partner. Rogers PCBs, PTFE PCBs, and hybrid stackups offer proven solutions for low loss, stable impedance, and scalable production.

By working with an experienced high frequency PCB manufacturer, engineers and procurement teams can confidently source PCBs that meet the demanding requirements of modern RF front-end applications.