As 5G technology continues to expand across sub-6 GHz and higher frequency bands, antenna performance has become a critical factor in wireless system reliability. The PCB material used for antenna design directly affects signal loss, radiation efficiency, and impedance stability. RO4003 PCB for 5G antenna applications has become a popular choice due to its excellent balance of RF performance, manufacturability, and cost.

RO4003 laminates from Rogers Corporation are specifically engineered for high-frequency applications, making them well suited for modern 5G antenna designs.

Why RO4003 PCB Is Ideal for 5G Antenna Design

RO4003 PCB for 5G antenna applications offers several key advantages:

-

Stable dielectric constant (Dk ≈ 3.38) across frequency

-

Low dissipation factor (Df ≈ 0.0027 @ 10 GHz)

-

Low insertion loss for high-frequency signal transmission

-

Excellent dimensional stability and thermal performance

These properties help maintain antenna efficiency and consistent RF performance in 5G systems.

RF Performance Benefits of RO4003 PCB for 5G Antennas

5G antenna designs demand precise RF behavior. RO4003 PCB supports:

-

Reduced signal attenuation at high frequencies

-

Improved radiation efficiency

-

Stable impedance over temperature and frequency

-

Consistent antenna tuning and bandwidth performance

Compared to standard FR-4, RO4003 PCB significantly reduces dielectric loss, making it more suitable for 5G antenna and RF front-end designs.

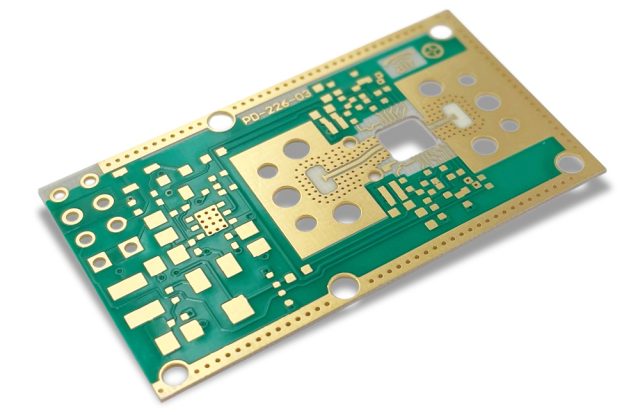

Impedance Control and Antenna Matching

Accurate impedance control is essential for 5G antenna performance. RO4003 PCB for 5G antenna fabrication enables:

-

Controlled impedance trace design

-

Precise stack-up configuration

-

Tight line width and spacing tolerance

-

Reliable impedance matching between antenna and RF circuits

This ensures minimal reflection loss and optimal antenna matching in 5G communication systems.

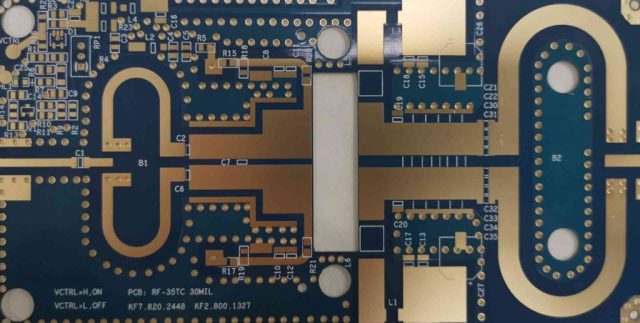

Manufacturing Considerations for RO4003 PCB

Producing RO4003 PCB for 5G antenna requires specialized manufacturing expertise, including:

-

RF material handling and storage control

-

Precise lamination and etching processes

-

Controlled copper thickness

-

RF-specific quality inspection and testing

An experienced high-frequency PCB manufacturer ensures consistent performance and high yield.

RO4003 PCB vs FR-4 for 5G Antenna Applications

| Feature | RO4003 PCB | FR-4 PCB |

|---|---|---|

| Dielectric Loss | Very Low | High at GHz |

| Dk Stability | Excellent | Poor |

| Impedance Control | High Precision | Limited |

| 5G Antenna Suitability | Excellent | Not Recommended |

For 5G antenna applications, RO4003 PCB clearly outperforms standard FR-4 materials.

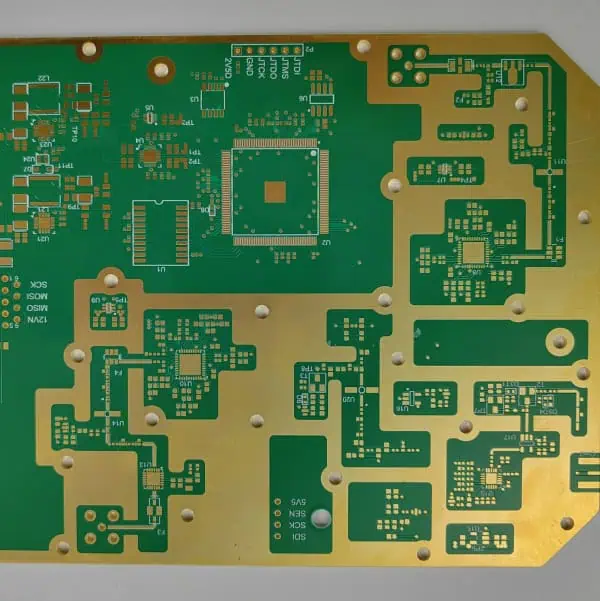

Typical Applications of RO4003 PCB in 5G Systems

RO4003 PCB for 5G antenna is widely used in:

-

5G base station antennas

-

Small cell and micro cell antennas

-

5G CPE and wireless terminals

-

RF front-end antenna modules

-

IoT and smart antenna systems

These applications benefit from stable RF performance and low signal loss.

Conclusion

Choosing the right PCB material is essential for reliable 5G antenna performance. RO4003 PCB for 5G antenna applications provides low loss, stable dielectric properties, and excellent manufacturability, making it an ideal solution for modern 5G wireless systems.

By working with an experienced high-frequency PCB manufacturer, designers and system integrators can fully leverage the advantages of RO4003 PCB to achieve efficient, stable, and scalable 5G antenna designs.