Satellite PCB: The Structural, Thermal, and RF Backbone of Modern Space Systems

Modern satellites—whether operating in LEO constellations, MEO navigation networks, or GEO communication platforms—depend entirely on the reliability of their Satellite PCB. The Satellite PCB is not simply a circuit board; it is a mission-critical aerospace PCB platform engineered to manage high-frequency RF routing, low-loss microwave transmission, thermal dissipation, radiation exposure, power delivery, and mechanical stability across years of orbit.

In space, there is no repair, no recalibration, no margin for error. A Satellite PCB must deliver absolute RF stability, thermal durability, dielectric consistency, and structural reliability under conditions far beyond terrestrial electronics.

Why Satellite PCB Engineering Exceeds Standard RF PCB Requirements

Environmental extremes in space impose enormous stress on every Satellite PCB:

• Continuous thermal cycling from –150°C to +125°C

• High-frequency power transmission across Ka-, Ku-, X-, and V-band

• Total ionizing dose exposure degrading ordinary PCB substrates

• Vacuum outgassing causing dielectric drift and delamination

• Shock and vibration loads during launch, separation, and deployment

• Zero-maintenance operation for 5–15 years

For these reasons, a Satellite PCB must integrate aerospace-grade materials, thermal-stable stackups, radiation-tolerant interfaces, and ultra-tight impedance control.

Aerospace-Grade Materials for High-Frequency Satellite PCB Reliability

KKPCB engineers Satellite PCBs using materials specifically optimized for low-loss microwave routing, stable dielectric constant, minimal Df drift, and high resistance to radiation:

• RO4835, RO3003, RO3006 — stable Dk/Df and radiation resistance

• RO5880 — ultra-low-loss routing for mmWave satellite links

• Polyimide-based space-grade substrates — high thermal endurance

• Ceramic-filled low-CTE laminates — dimensional stability

• Aerospace bonding films — reduced outgassing and molecular breakdown

These materials ensure Satellite PCB dielectric stability across multi-year radiation exposure, preserving RF chain integrity even under severe orbit conditions.

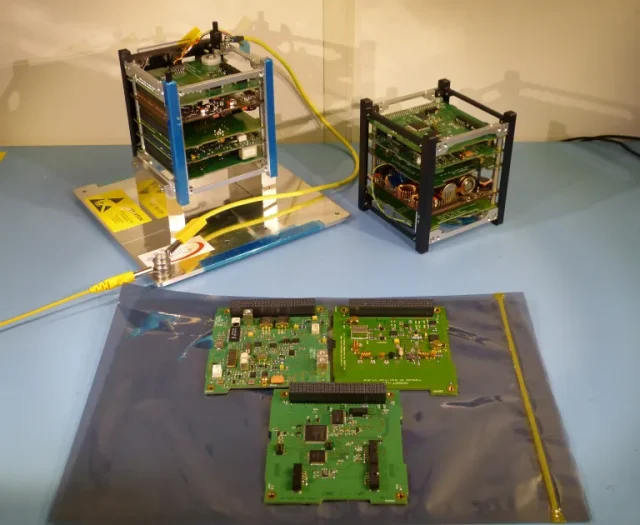

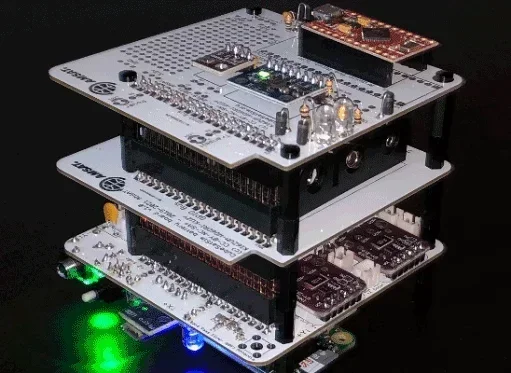

High-Density Satellite PCB Stackups for RF, Digital, and Power Co-Integration

The Satellite PCB is the convergence point of RF communication layers, digital processing layers, beamforming networks, power distribution systems, and thermal conduction structures.

1. Dielectric Stability & Low-Loss RF Transmission

Satellite PCB RF layers maintain <0.2 dB/in loss at mmWave frequencies and preserve phase accuracy for beamforming and MIMO payloads.

2. CTE-Balanced Mechanical Architecture

Balanced copper and dielectric layers suppress warpage, microvia fatigue, and Z-axis expansion in vacuum thermal cycling.

3. Radiation-Hardened Layer Interfaces

Satellite PCB bonding systems are engineered to resist electron flux, proton bombardment, and molecular decomposition.

4. Embedded Heat-Conduction Networks

Copper planes, filled microvias, and ceramic substrates dissipate heat from PAs, LNAs, beamformers, and digital ASICs.

5. Isolation for RF–Digital–Power Domains

Layer partitioning reduces EMI, minimizes coupling, and stabilizes satellite transceiver performance across wideband frequencies.

These design principles guarantee that Satellite PCB architectures remain predictable, low-loss, and mechanically stable through launch, operation, and long-term orbit.

Thermal Engineering: The Core Limitation of Every Satellite PCB

Since space has no convection, every watt of heat must pass through the Satellite PCB itself. KKPCB builds Satellite PCB designs with:

• Laser-drilled, copper-filled microvias for vertical heat extraction

• Multi-plane heat-spreading layers under high-power RF components

• Ceramic-enhanced dielectrics with superior thermal conductivity

• Polyimide systems engineered for high-temperature endurance

• Symmetric stackups minimizing thermomechanical stress

These solutions maintain RF phase stability, protect high-power amplifiers, and prevent thermal drift in mmWave communication chains.

High-Frequency Integrity in Satellite RF Payloads

Modern satellite communication systems rely heavily on Ka-band, Ku-band, and emerging V-band links, where even nanometer-level variations in the Satellite PCB affect system performance. KKPCB ensures:

• Highly stable impedance (<3% deviation) across antenna arrays

• Ultra-low insertion loss for long-distance satellite RF chains

• Phase coherence essential for beam-steering accuracy

• Minimal dielectric drift across multi-year mission radiation cycles

• Precision mmWave routing for dense phased-array panels

In high-density satellite payloads, RF performance is directly tied to Satellite PCB material quality and routing precision.

Radiation, Outgassing, and Structural Qualification for Satellite PCB

KKPCB validates every Satellite PCB through aerospace-grade testing:

• Outgassing certification per ASTM E595

• Thermal shock cycles from –150°C to +130°C

• Proton/electron radiation simulation

• Random vibration & pyroshock per MIL-STD-810

• mmWave RF chain endurance validation

• CTE mapping across full lamination cycles

These tests ensure the Satellite PCB maintains mechanical integrity, dimensional stability, and RF consistency throughout its entire mission profile.

Satellite PCB: The Foundation of Every Space Mission

Every satellite—communications, Earth observation, navigation, defense, broadband, or scientific—depends on the uncompromised reliability of its Satellite PCB.

If the Satellite PCB fails, the entire spacecraft becomes inoperable.

KKPCB delivers Satellite PCBs engineered for:

• Long-term dielectric stability

• High-frequency, low-loss RF routing

• Thermal endurance in vacuum

• Radiation-resistant performance

• Mechanical robustness during launch & orbit

• Stable impedance for Ka-/Ku-/V-band payloads

As space systems evolve toward high-density phased arrays, laser communications, inter-satellite RF links, and massive LEO constellations, Satellite PCB engineering becomes the decisive factor in mission success.