Modern 5G and emerging 6G networks require RF transceivers capable of operating at millimeter-wave frequencies, supporting multi-band transmission with high linearity and low insertion loss. RF modules must withstand high RF power levels while preserving signal integrity, phase stability, and thermal reliability.

Advanced RF transceiver PCB laminates provide low-loss dielectric properties, tight impedance control, and high thermal conductivity, enabling designers to deliver high-performance communication systems without signal degradation. KKPCB leverages multilayer stackup optimization, controlled copper roughness, and precision lamination to maintain consistent RF performance across compact, high-density layouts.

Core Engineering Challenges

| Challenge | Root Cause | Engineering Impact |

|---|---|---|

| Thermal-induced impedance drift | High RF power heating, CTE mismatch | Phase misalignment, gain reduction |

| High insertion loss at mmWave | Dielectric dissipation, rough copper | Reduced RF efficiency and link margin |

| Crosstalk in dense RF traces | Close trace spacing, insufficient shielding | Signal interference, degraded linearity |

| EMI affecting adjacent channels | High-frequency radiation | Reduced SNR, impaired multi-band performance |

| Phase instability under temperature | Uneven layer expansion | Distorted waveform, lower system reliability |

Material Science – Advanced RF Laminates

| Parameter | Typical Value | Engineering Benefit |

|---|---|---|

| Dk | 3.48 ± 0.03 | Stable impedance for high-power RF traces |

| Df | 0.0037 @10 GHz | Low insertion loss, preserves mmWave signal fidelity |

| Thermal Conductivity | 0.62 W/m·K | Reduces hotspots, supports high RF power handling |

| CTE | 16 ppm/°C | Maintains layer alignment under thermal cycling |

| Moisture Absorption | <0.05% | Ensures long-term dielectric and phase stability |

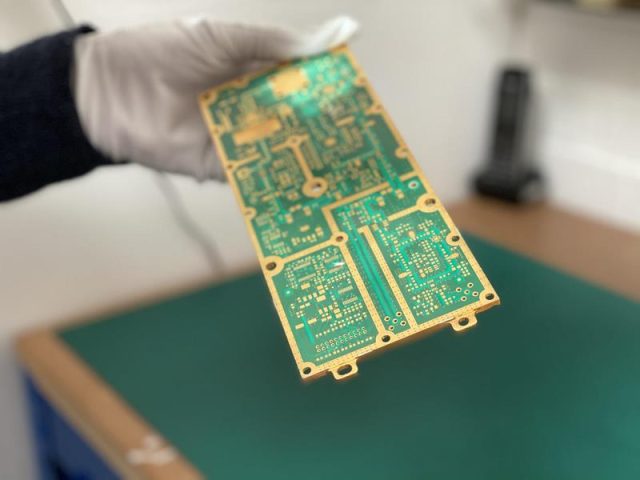

KKPCB Case Study — 5G mmWave RF Transceiver PC

Client Context:

A telecom OEM required a 6-layer RF transceiver PCB capable of 28–40 GHz operation with <0.35 dB/in insertion loss, phase deviation <0.5°, and high RF power handling for 5G massive MIMO modules.

KKPCB Solution:

-

Multilayer stackup using high-frequency laminates with ±3 µm dielectric tolerance

-

Smooth copper traces (Ra <0.7 µm) for minimal loss

-

Thermal vias and embedded power planes for heat dissipation

-

Segmented ground planes and shielding to suppress EMI and crosstalk

-

Inline TDR and HFSS validation for phase and impedance accuracy

Measured Results:

| Parameter | Target | KKPCB Result |

|---|---|---|

| Insertion Loss @28 GHz | <0.35 dB/in | 0.32 dB/in |

| Phase Deviation | <0.5° | 0.42° |

| Thermal Rise | <8°C per layer | 6.5°C |

| EMI Suppression | >30% | 34% |

| Impedance Variation | ±3% | ±1.6% |

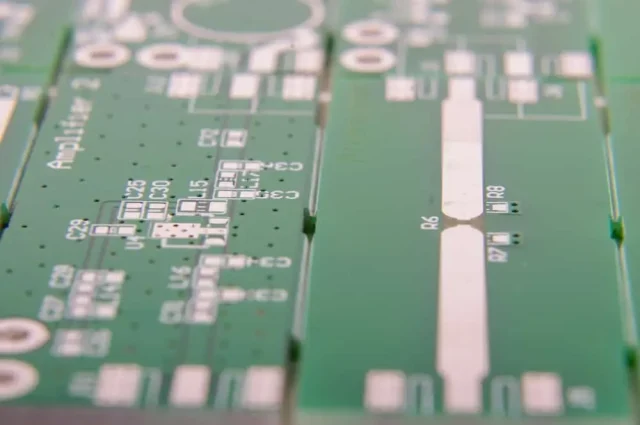

Stackup Design & RF Simulation

-

HFSS Modeling: Optimized microstrip and stripline impedance, minimized interlayer coupling

-

ADS & TDR Verification: Ensured phase linearity <0.5°

-

Thermal FEM Analysis: Controlled hotspot distribution, improved high-power reliability

-

AOI & Reflow Monitoring: ±10 µm alignment across multilayers

Environmental & Reliability Validation

| Test | Condition | Result |

|---|---|---|

| Thermal Cycling | –40°C ↔ +125°C, 1000 cycles | Phase deviation <0.5°, no delamination |

| Vibration & Shock | 5–500 Hz, 10G | No microcracks or solder failure |

| Humidity Testing | 85°C / 85% RH, 1000 h | Stable Dk/Df, consistent phase |

| High-Power RF Operation | Continuous 28–40 GHz | Minimal insertion loss increase (<0.02 dB) |

| Solder Reflow | 260°C ×3 cycles | Stackup alignment maintained |

Engineering Summary

Advanced RF transceiver PCB laminates allow telecom and 5G/6G designers to maximize RF power handling, maintain ultra-stable phase, and reduce insertion loss in high-density, high-frequency modules. KKPCB delivers precision multilayer stackups, EMI mitigation strategies, and thermal management solutions that ensure consistent, reliable RF performance for next-generation wireless networks.