Essential RF Amplifier Knowledge for Modern PCB Manufacturers | KKPCB

As wireless communication, IoT connectivity, radar sensing, and high-speed data links continue to evolve, RF amplifiers have become one of the most critical building blocks in modern electronics. For PCB manufacturers, understanding how RF amplifiers work—and how PCB design impacts their performance—is essential to delivering high-reliability RF systems.

At KKPCB, we work closely with RF designers, module manufacturers, and system integrators to ensure that PCB materials, layout strategies, impedance structures, and thermal solutions align perfectly with the demanding requirements of RF amplification.

This guide offers a comprehensive overview of RF amplifiers from a PCB manufacturer’s perspective.

What Is an RF Amplifier?

An RF amplifier increases the power of a radio-frequency signal so it can be transmitted over long distances or processed with higher fidelity. It operates within specific frequency bands ranging from MHz to tens of GHz, depending on the application.

At the core of every RF amplifier are high-speed transistors—GaAs, GaN, SiGe, or CMOS—capable of switching millions of times per second, reproducing a low-power signal at much higher amplitude.

RF amplifiers are found in:

-

Radar systems

-

Scientific instrumentation

-

Military communication platforms

Types of RF Amplifiers

Different amplifier classes offer different trade-offs in linearity, efficiency, and complexity. Understanding these distinctions is critical for selecting the proper PCB materials and matching networks.

Class A

-

Highest linearity

-

Very low distortion

-

Poor efficiency

-

Used for precision, low-noise applications

Class B

-

Push-pull design

-

Higher efficiency than Class A

-

Moderate distortion

Class AB

-

Hybrid of Class A and B

-

Good balance between linearity and efficiency

-

Widely used in RF communication

Class C

-

Conducts for less than 180° of waveform

-

Very high efficiency

-

High distortion—unsuitable for high-linearity applications

Class D, E, and F

-

Switching amplifiers

-

Extremely high efficiency

-

Require filtering to manage switching noise

-

Ideal for high-frequency or high-power designs

Where RF Amplifiers Are Used

RF amplifiers play an essential role across many industries:

-

Wireless communication (cellular, Wi-Fi, 5G, satellite)

-

Broadcasting (radio, TV)

-

Radar systems (military, automotive, aviation)

-

Medical equipment (MRI, RF ablation devices)

-

Industrial heating (RF energy systems)

-

Scientific research (particle accelerators, spectroscopy)

Each application has unique requirements for gain, linearity, power output, and frequency range.

Key Design Considerations for RF Amplifiers

1. Frequency Coverage

Typical ranges span 500 MHz–5 GHz, though mmWave systems may exceed 30 GHz.

2. Gain

Standard gain requirements fall between 10–20 dB, with minimal variations across operating bandwidth.

3. Impedance Matching (50 Ω Standard)

The input and output impedance must match 50 Ω to ensure:

-

Maximum power transfer

-

Minimal signal reflection

-

High efficiency

PCB designers must tightly control trace width, dielectric materials, and ground referencing.

4. Noise Figure

As frequency increases, noise rises. RF amplifiers typically require NF < 2–3 dB.

5. Output Power

Measured in dBm, typical output levels range from:

-

Small-signal amplifiers: 0–12 dBm

-

Driver amplifiers: 10–20 dBm

-

Power amplifiers: 20–40+ dBm

6. Linearity Metrics

-

1 dB Compression Point (P1dB)

-

Third-Order Intercept Point (IP3)

These determine whether amplified signals remain distortion-free.

7. Semiconductor Technology

-

GaAs – widely used for RF front ends

-

GaN – high-power, high-frequency, high heat resistance

-

SiGe – excellent for low-noise, high-frequency designs

-

CMOS – cost-effective, good for integration

8. Power Consumption

Supply voltages typically range 1.8–6 V, with current from 20–100 mA depending on amplifier class.

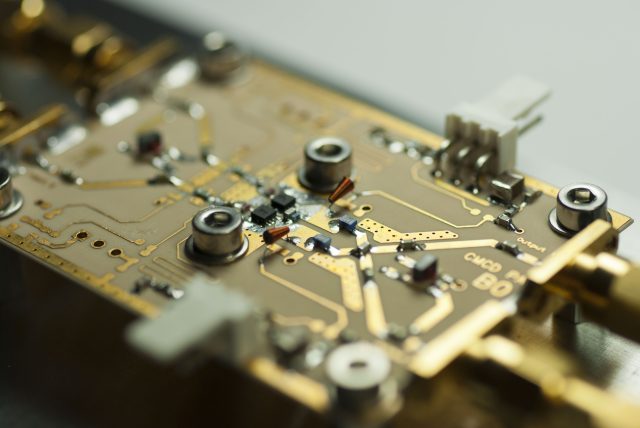

9. Thermal Management

RF amplifiers generate substantial heat due to high-frequency switching.

PCB engineers must optimize:

-

Copper thickness

-

Thermal vias

-

Metal substrates (e.g., MCPCB)

-

Heat sinks and spreaders

10. Packaging

Compact IC and module footprints (4–25 mm²) require precise placement and controlled-impedance routing.

Matching Networks & Impedance Matching

Matching networks ensure that the amplifier sees a matched load at both input and output.

Common Matching Network Types

-

L-network

-

Pi-network

-

T-network

-

Quarter-wave transformers

-

Transmission line matching

Key considerations:

-

Components must be high-Q, low-loss

-

Maintain broadband performance if wide frequency operation is required

-

Choose passive (L, C) or active matching depending on application

Proper matching maximizes efficiency and minimizes return loss.

Power Amplifiers: Special Requirements

Power amplifiers (PAs) demand additional engineering focus:

-

High output power (watts to kilowatts)

-

High efficiency to reduce energy loss

-

Excellent linearity to prevent distortion

-

Thermal robustness (heat dissipation is critical)

-

Stability across temperature, load conditions, and frequency

-

Broadband operation for multi-band platforms

-

Integrated protection circuits (over-voltage, over-current, VSWR protection)

GaN-based power amplifiers are becoming the new standard for high-power RF applications due to their superior thermal and electrical performance.

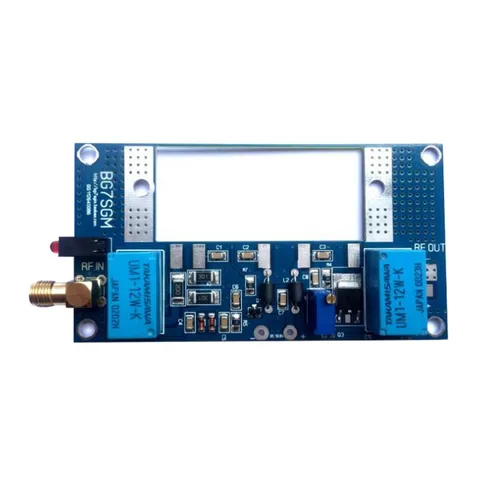

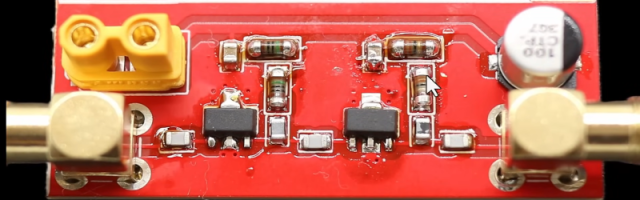

RF Amplifier Modules & Integrated Circuits

Using modular RF amplifiers or ICs can dramatically reduce development time.

Advantages

-

Shorter design cycles

-

Improved reliability

-

Reduced assembly complexity

-

Lower development cost

Considerations

-

Compatibility with surrounding circuitry

-

Need for additional matching networks

-

Component availability and lead times

-

Thermal and mechanical requirements

Evaluation kits further simplify validation and allow engineers to verify real-world performance before final integration.

Summary

RF amplifiers are indispensable in nearly every modern electronic system. To ensure optimal performance, engineers must balance:

-

Gain

-

Linearity

-

Efficiency

-

Noise

-

Impedance

-

Thermal management

For PCB manufacturers like KKPCB, understanding RF amplifier behavior is crucial. PCB material selection, stack-up engineering, copper routing, ground design, and thermal strategies all have a profound impact on RF amplifier efficiency, stability, and reliability.

By mastering these principles, designers can produce RF systems that deliver clean, high-fidelity, and stable signals across a wide range of applications.