Medical PCB Manufacturing: Technologies, Design, and the Future of Electronic Healthcare

As medical technology continues to evolve, diagnostics and treatments increasingly depend on sophisticated automated systems. These systems rely on high-precision PCBs (Printed Circuit Boards)—miniaturized, high-density circuit assemblies that integrate numerous components within limited space. To guarantee performance, medical PCB assemblies incorporate advanced design features that enhance electrical reliability, mechanical stability, and patient safety.

KKPCB provides comprehensive design, engineering, prototyping, and manufacturing services for medical PCBs. From early-stage prototypes to full-scale production, we ensure every medical electronics project adheres to strict industry standards through rigorous process control, quality assurance, and traceability. This empowers medical innovators to launch cutting-edge products faster and with confidence.

Advanced Technologies Used in Medical PCBs

Modern medical devices mirror the trends seen in consumer and industrial electronics—smaller footprint, higher functionality, and greater integration. This shift significantly increases the complexity of PCB design and manufacturing. PCB layouts must account for component density, trace spacing, thermal challenges, and stringent electrical performance, leaving almost no margin for error.

Below are the key technologies enabling next-generation medical PCB innovation:

1. HDI (High-Density Interconnect) PCBs

HDI technology allows designers to place more components in smaller areas through:

-

Microvias and stacked vias

-

Ultra-fine traces and spaces

-

High layer count in compact form

This is crucial in compact medical devices requiring advanced features such as:

-

Wearable biomonitors

-

Portable diagnostic systems

-

Implantable devices

-

Smart drug-delivery platforms

HDI solves routing constraints and enhances electrical performance while improving device miniaturization.

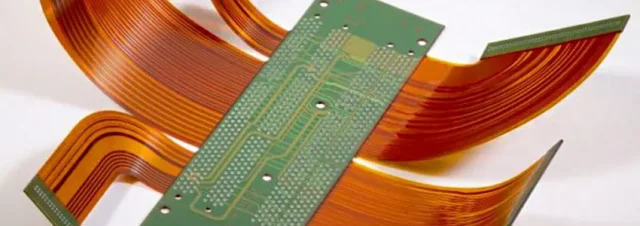

2. Flex and Rigid-Flex PCBs

Many medical devices no longer conform to traditional rectangular PCB shapes. Applications such as wearables, handheld diagnostics, and implantable devices benefit immensely from flexible PCB technologies.

Benefits of Flex & Rigid-Flex PCBs:

-

Fit into irregular or extremely tight spaces

-

Lightweight design for portable and wearable devices

-

Improved shock/vibration resistance

-

Reduced connector count (using flat-cable transitions)

-

Lower assembly complexity and cost

-

Increased design freedom and ergonomics

Although flex PCB design requires more expertise, it drastically enhances device reliability and user comfort—making it indispensable in next-generation medical electronics.

Medical PCB Design Principles

Designing a medical PCB is a highly technical and safety-critical process. Engineers must thoroughly understand electrical behavior, material characteristics, signal integrity, and circuit theory to achieve reliable outcomes.

Key design considerations include:

1. EMC (Electromagnetic Compatibility)

Medical devices must operate without signal interference. Even minor EMC issues can result in:

-

Incorrect diagnostic readings

-

Device malfunctions

-

Safety hazards

Thus, careful attention must be paid to:

-

Grounding strategies

-

Shielding

-

Filter design

-

Trace routing

-

Component placement

2. Component Integration

Medical PCBs generally include:

-

Resistors and capacitors

-

Power modules

-

Sensors

-

Connectors and packaging elements

SMT (Surface-Mount Technology) and Flex PCBs are now widely used to meet miniaturization requirements.

3. Environmental & Safety Requirements

Medical devices must withstand:

-

Temperature fluctuations

-

Mechanical shocks

-

Frequent sterilization

-

Long-term reliability demands

PCB materials and design techniques must support high durability and patient safety.

Medical PCB Manufacturing

With the rapid advancement of medical technologies, PCB manufacturing must meet the highest standards of precision, consistency, and traceability.

KKPCB provides:

• Prototype & full-scale medical PCB production

Supporting R&D teams, startups, and established manufacturers through each stage.

• Assembly & integration

Including advanced SMT, BGA, micro-BGA, and mixed-technology assembly.

• Comprehensive testing

Such as functional testing, AOI, X-ray inspection, ICT, and reliability validation.

• Full compliance with medical PCB standards

Ensuring adherence to industry regulations through stringent process control, documentation, and traceability.

The result is faster time-to-market, reduced development risks, and medical products that meet global safety expectations.