Industrial IoT PCB Innovation: The Core of Intelligent Manufacturing

1. Introduction: The Intelligent Backbone of Industry 4.0

The Industrial Internet of Things (IIoT) represents the convergence of machines, sensors, and intelligent electronics into a unified, connected ecosystem. By enabling seamless communication between devices and systems, IIoT is transforming traditional manufacturing into smart, self-optimizing environments.

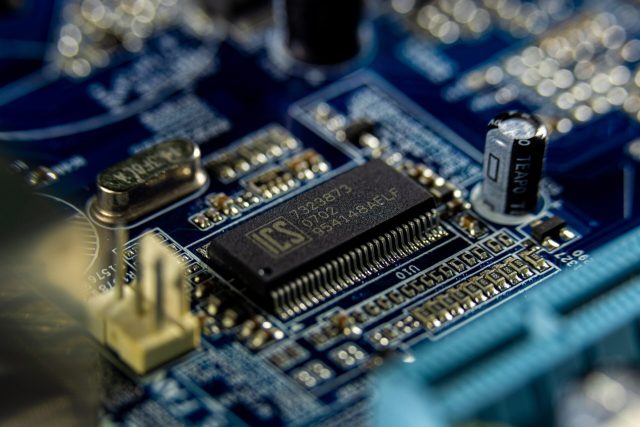

At the center of this transformation is the Industrial IoT PCB (Printed Circuit Board)—the foundation upon which smart devices sense, compute, and communicate. Every layer of copper trace and substrate becomes a pathway for real-time data, driving the intelligence of modern industry.

2. Engineering for Industrial Resilience

Unlike standard consumer electronics, Industrial IoT PCBs are designed for long-term reliability under harsh operating conditions—high temperatures, vibrations, chemical exposure, and electromagnetic interference.

Key technical parameters that define their resilience include:

-

Advanced Material Systems: High-performance substrates such as Rogers, PTFE, or aluminum-based laminates with low dielectric loss.

-

Thermal Reliability: Conductive layers and metal-core PCBs that dissipate heat efficiently for continuous 24/7 operation.

-

Signal Integrity: Controlled impedance routing and low-loss materials ensure accurate data transmission in RF and high-speed circuits.

-

EMC Shielding & Grounding: Multi-layer design with optimized copper distribution to reduce noise and interference.

-

Durability Standards: Conformance to IPC Class 3 and industrial-grade testing for long lifecycle performance.

3. The Functional Role of PCBs in the IIoT Ecosystem

Industrial IoT PCBs act as the nervous system of the connected factory. They enable real-time monitoring, process automation, and intelligent decision-making by bridging sensors, processors, and communication networks.

Core Application Domains

-

Sensor Networks: Embedded PCBs enable compact sensor modules for pressure, temperature, and vibration analysis.

-

Edge Computing Devices: Process data locally to reduce latency and improve system efficiency.

-

Industrial Controllers (PLCs, HMIs): Stable PCB platforms power automation control and safety systems.

-

Connectivity Modules: Support for Ethernet, CAN, Wi-Fi, Zigbee, and 5G ensures seamless interoperability.

-

Predictive Maintenance Systems: High-frequency PCBs handle advanced analytics and fault detection.

By integrating these systems, PCBs form the physical foundation of industrial intelligence—where machines learn, adapt, and optimize production in real-time.

4. Advanced PCB Technologies Shaping Industrial IoT

KKPCB’s engineering approach combines innovation with precision manufacturing to meet the challenges of next-generation IIoT systems.

Technology |

Functionality & Benefit |

|---|---|

| High-Frequency PCB Design | Enables ultra-low signal loss and consistent impedance for wireless communication systems. |

| Rigid-Flex PCB Solutions | Provides mechanical adaptability for compact and dynamic industrial systems. |

| Metal-Core & Ceramic PCB | Enhances heat dissipation for power modules and motor control boards. |

| HDI & Multi-Layer Structures | Supports complex circuit density and miniaturization for embedded IoT systems. |

| Conformal Coating & Surface Protection | Prevents corrosion, oxidation, and contamination in extreme environments. |

KKPCB’s design philosophy centers on reliability by design, ensuring that every PCB functions as a stable, long-life platform for mission-critical applications.

5. Design Intelligence: Integrating DFM, DFT, and EMC Strategy

Smart PCB engineering begins at the design stage. KKPCB’s approach integrates Design for Manufacturability (DFM), Design for Testability (DFT), and Electromagnetic Compatibility (EMC) strategies to achieve both functional and economic optimization.

-

DFM minimizes production errors, ensuring precision in drilling, plating, and soldering.

-

DFT ensures every critical node is accessible for in-circuit and functional testing.

-

EMC Optimization reduces signal coupling and crosstalk through ground-plane management and trace geometry refinement.

This holistic methodology empowers designers to achieve high-speed, low-noise, and thermally stable PCB architectures suited for industrial automation systems.

6. Why KKPCB Leads in Industrial IoT PCB Manufacturing

KKPCB has established itself as a trusted global provider of high-reliability PCB and PCBA solutions for industrial electronics. Our competitive edge includes:

-

Precision Fabrication: State-of-the-art HDI, microvia, and laser drilling technologies.

-

Comprehensive Quality Control: AOI, flying probe, X-ray inspection, and reliability testing for zero-defect assurance.

-

Engineering Expertise: Collaborative support in layout optimization, stack-up design, and thermal analysis.

-

Fast Global Delivery: Efficient production systems and logistics for large-scale deployments.

At KKPCB, we don’t just build printed circuit boards—we build the electronic infrastructure of intelligent industries.

7. Conclusion

Industrial IoT PCBs are not just circuit carriers—they are the connective tissue of Industry 4.0, linking physical machinery with digital intelligence.

By combining material science, electrical engineering, and precision manufacturing, KKPCB continues to empower the global transition toward smart, sustainable, and self-aware manufacturing systems.