As operating frequencies increase, signal loss becomes a dominant factor affecting system performance. For RF, microwave, and high-speed digital designs, selecting a qualified low loss high frequency PCB supplier is essential to maintaining signal integrity, reducing attenuation, and ensuring consistent electrical performance.

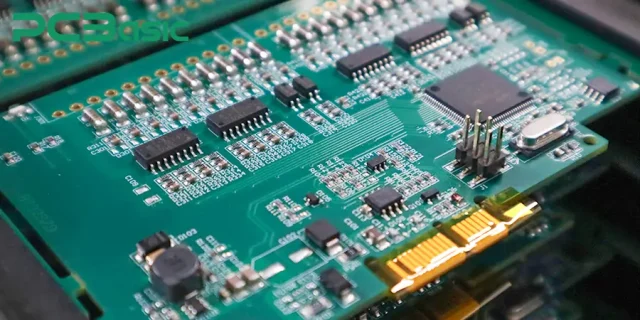

Low loss PCB manufacturing requires more than standard fabrication—it demands deep expertise in materials, stackup design, and process control.

What Defines a Low Loss High Frequency PCB?

A low loss high frequency PCB is engineered to minimize both dielectric loss and conductor loss at elevated frequencies. These losses directly affect insertion loss, phase stability, and overall system efficiency.

A professional low loss high frequency PCB supplier focuses on controlling every factor that contributes to signal degradation.

Materials Used by Low Loss High Frequency PCB Suppliers

Material selection is the foundation of low loss performance. Experienced suppliers work with:

-

Rogers RO4003, RO4350, and RO3003 series

-

PTFE-based and ceramic-filled laminates

-

Duroid 5880 for microwave and radar applications

-

Hybrid stackups combining RF laminates with FR-4

Low dissipation factor (Df) and stable dielectric constant (Dk) are critical for high frequency signal transmission.

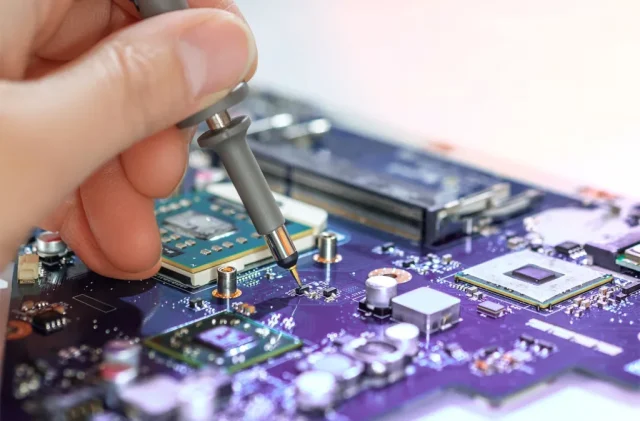

Manufacturing Processes That Reduce Signal Loss

A qualified low loss high frequency PCB supplier applies advanced manufacturing techniques such as:

-

Fine-line etching to reduce impedance variation

-

Copper surface roughness control to minimize conductor loss

-

Precise dielectric thickness management

-

Optimized lamination and registration processes

These process controls directly impact RF performance.

Controlled Impedance and Low Loss Performance

Low loss PCB design is inseparable from impedance control. Professional suppliers provide:

-

Stackup simulation and impedance calculation

-

Tight impedance tolerance control

-

TDR impedance measurement and verification

Accurate impedance control minimizes reflections that contribute to additional signal loss.

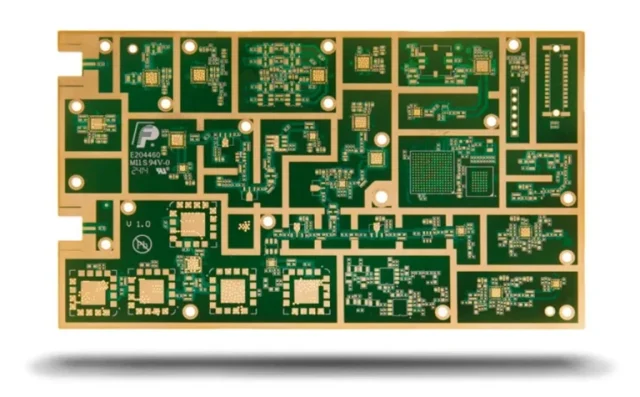

Applications Requiring Low Loss High Frequency PCBs

Low loss high frequency PCB suppliers support demanding applications including:

-

RF and microwave communication systems

-

5G and mmWave front-end modules

-

Automotive radar and ADAS electronics

-

High-speed networking and data center hardware

-

Aerospace and defense electronics

Each application relies on stable, low-attenuation signal paths.

How to Choose a Low Loss High Frequency PCB Supplier

When evaluating a low loss high frequency PCB supplier, consider:

-

Experience with RF and microwave materials

-

Proven low loss PCB manufacturing processes

-

Controlled impedance capability and testing

-

Engineering support during design and prototyping

-

Ability to scale from prototype to mass production

A reliable supplier acts as a long-term technical partner.

Conclusion

A professional low loss high frequency PCB supplier plays a critical role in the performance of RF and high-speed electronic systems. Through advanced materials, precision manufacturing, and controlled impedance processes, low loss PCB suppliers ensure minimal signal attenuation and consistent electrical performance.

Choosing the right low loss high frequency PCB supplier ensures your designs meet demanding performance requirements while maintaining manufacturing stability and scalability.