Duroid PCB: Ultra-Low Loss Material for RF & Microwave Applications

In today’s high-frequency world, industries such as 5G communication, satellite systems, radar sensing, aerospace electronics, and advanced wireless devices require PCB materials that can deliver stable performance at RF and microwave frequencies.

Standard FR4 materials may work well for general electronics, but they often introduce higher loss and unstable dielectric behavior when frequency increases. That’s why many engineers choose Duroid PCB—a well-known solution for ultra-low loss and high-frequency circuit performance.

In this article, we’ll explain what Duroid PCB is, its advantages, typical applications, and important manufacturing considerations.

What Is Duroid PCB?

Duroid PCB generally refers to a printed circuit board made from PTFE-based high-frequency laminates, commonly associated with Rogers RT/duroid® materials.

Duroid laminates are designed for high-frequency performance and are widely used in RF and microwave circuits because they offer:

-

Very low dielectric loss (low Df)

-

Stable dielectric constant (Dk)

-

Excellent signal integrity at high frequencies

-

High reliability for demanding environments

Due to these characteristics, Duroid PCB is often used in high-end RF applications where low insertion loss and stable impedance control are critical.

Key Benefits of Duroid PCB

1. Ultra-Low Loss for High-Frequency Signals

One of the biggest advantages of Duroid PCB is its extremely low dielectric loss, which helps reduce signal attenuation.

This is especially important for:

-

Microwave transmission lines

-

High-frequency antennas

-

RF power amplifiers

-

Long trace routing in RF systems

Lower loss means better efficiency and stronger signal performance.

2. Stable Dielectric Constant (Dk)

Duroid materials are known for stable Dk behavior across frequency ranges, which helps achieve:

-

Accurate impedance matching

-

Stable phase response

-

Consistent RF performance

This is essential for precision RF components such as filters, couplers, and antenna feed networks.

3. Excellent Signal Integrity and Repeatability

At high frequencies, small variations in material properties can cause major performance changes. Duroid PCB helps ensure:

-

Reduced signal distortion

-

Lower reflection and mismatch

-

Improved repeatability in production

This makes Duroid PCB suitable for both prototyping and volume production of RF boards.

4. Strong Reliability for Harsh Environments

Duroid PCB is commonly used in applications requiring long-term stability, such as aerospace and defense electronics. Many Duroid laminates provide:

-

Good thermal stability

-

Resistance to environmental stress

-

Reliable performance under temperature cycling

Common Applications of Duroid PCB

Duroid PCB is widely used across industries that demand high-frequency performance.

RF and Microwave Antennas

Duroid PCB is frequently used in antenna designs such as:

-

Patch antennas

-

Antenna arrays

-

Phased-array antennas

Its low loss properties help improve antenna efficiency and gain.

Radar Systems

Radar applications often require stable high-frequency performance. Duroid PCB supports radar modules used in:

-

Automotive radar

-

Industrial radar sensors

-

Aerospace radar systems

Satellite Communication Equipment

Duroid PCB is commonly found in:

-

Satellite RF modules

-

Ground station microwave circuits

-

High-frequency communication links

Stable dielectric performance ensures consistent signal transmission.

Aerospace and Defense Electronics

Duroid PCB is widely selected for aerospace systems due to its reliable performance in extreme conditions, including:

-

Navigation systems

-

RF sensors

-

Communication equipment

Duroid PCB vs FR4: Why Duroid Performs Better at High Frequencies

FR4 is widely used for general PCB applications, but it becomes less suitable for high-frequency RF designs.

| Feature | FR4 PCB | Duroid PCB |

|---|---|---|

| Dielectric Loss | Higher | Much lower |

| Dk Stability | Moderate | Excellent |

| RF/Microwave Performance | Limited | Strong |

| Impedance Control | Less consistent | Highly consistent |

| Typical Use | General electronics | RF & microwave circuits |

For RF and microwave designs, Duroid PCB provides a significant performance advantage.

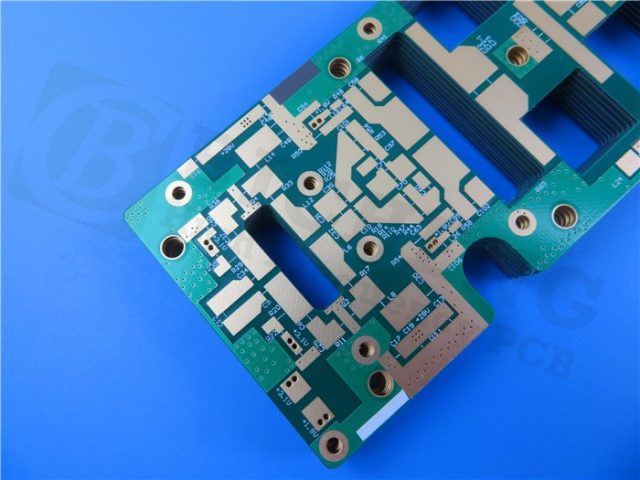

Duroid PCB Manufacturing Considerations

Manufacturing Duroid PCB requires specialized experience and process control due to PTFE-based material characteristics.

Key considerations include:

Material Handling and Lamination

PTFE-based laminates require optimized lamination conditions to ensure:

-

Strong bonding strength

-

Stable thickness control

-

Reduced risk of delamination

Precision Etching and Trace Control

RF traces must be manufactured with high accuracy to maintain impedance consistency. Fine control of:

-

Trace width

-

Copper thickness

-

Etching tolerance

is essential for stable performance.

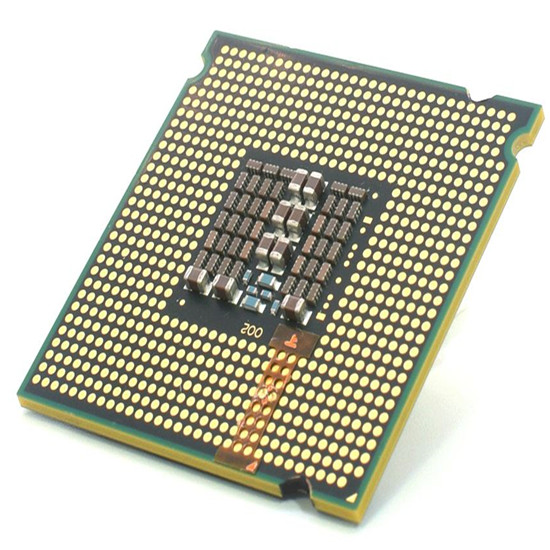

Drilling and Via Reliability

For multi-layer RF boards, drilling and via quality must be controlled carefully to avoid:

-

Plating defects

-

Signal discontinuities

-

Reliability issues in thermal cycling

Controlled Impedance Testing

Since Duroid PCB is often used for RF transmission lines, controlled impedance verification helps ensure the board meets design targets.

How to Choose the Right Duroid PCB Supplier

When selecting a Duroid PCB supplier, consider:

-

Experience with PTFE-based materials

-

Ability to produce controlled impedance RF structures

-

Stable process control and inspection systems

-

Engineering support for stack-up and DFM review

-

Reliable lead time and quality consistency

A professional supplier can help reduce risk and ensure your RF board performs as expected.

Conclusion

Duroid PCB is an excellent choice for high-frequency and microwave applications requiring ultra-low loss, stable dielectric performance, and high reliability. It is widely used in antennas, radar systems, satellite communication, and aerospace electronics, helping engineers achieve strong signal integrity and consistent performance.

If your project requires high-frequency performance beyond standard FR4, Duroid PCB is one of the most trusted material solutions available.