How Rogers RO4835 Material Enables Stable RF Performance in Harsh Environments

The Growing Demand for Thermally Stable, Low-Loss PCBs

As 5G networks, automotive radar, and satellite communications evolve toward millimeter-wave frequencies (24–77 GHz), PCB materials face increasing performance pressure.

Engineers now require substrates that maintain low insertion loss, tight dielectric control, and thermal stability under continuous high-power operation.

Traditional FR-4 materials often fail at these levels—exhibiting dielectric drift, CTE mismatch, and RF attenuation under high temperatures.

This performance gap led to the adoption of Rogers RO4835, a high-frequency laminate designed specifically for stable electrical performance across wide thermal ranges.

What Makes RO4835 PCB Different

Rogers RO4835 is a hydrocarbon ceramic-filled laminate optimized for long-term reliability and oxidation resistance—two crucial factors for RF and high-frequency modules operating outdoors or in automotive conditions.

| Property | Typical Value | Engineering Benefit |

|---|---|---|

| Dielectric Constant (Dk) @ 10 GHz | 3.48 ± 0.05 | Stable impedance and predictable RF behavior |

| Dissipation Factor (Df) | 0.0037 | Low loss for high-frequency signal integrity |

| In-Plane CTE | 11 ppm/°C | Excellent dimensional stability |

| Decomposition Temperature (Td) | > 380°C | High thermal reliability during lamination |

| Oxidation Resistance | Enhanced vs. RO4350B | Improved long-term electrical performance |

RO4835’s enhanced resin chemistry reduces oxidative degradation over time, maintaining Dk and Df consistency even after thousands of thermal cycles between –40°C and +150°C.

This makes it particularly suitable for automotive radar modules, 5G transceiver boards, and satellite RF front-end designs that must endure harsh climates.

RO4835 in 5G and Radar Systems

1. 5G Massive MIMO and Beamforming Modules

In 5G base stations, multi-channel beamforming antennas demand tight phase stability and low dielectric variation.

RO4835’s consistent Dk ensures that signal phase remains aligned across array elements, enabling clean beam steering and low insertion loss at frequencies above 28 GHz.

Industry Example:

A global telecom OEM adopted RO4835 PCB hybrid stackups for a 28 GHz phased-array module.

The result was 7.8% lower transmission loss and 5x better impedance stability compared to FR-4-based prototypes.

2. Automotive 77 GHz Radar Systems

For automotive radar, reliability under thermal stress is critical. Modules near engine compartments or bumpers can reach >120°C during operation.

RO4835’s low CTE and high Tg minimize warpage and maintain RF performance even after extended thermal cycling.

Case Insight:

A Tier-1 radar supplier switched from RO4350B to RO4835 + 4450F bonding film for improved oxidation stability.

After 1,000 hours of 150°C aging, dielectric drift was reduced from ±0.07 to ±0.02, extending radar calibration life and signal stability.

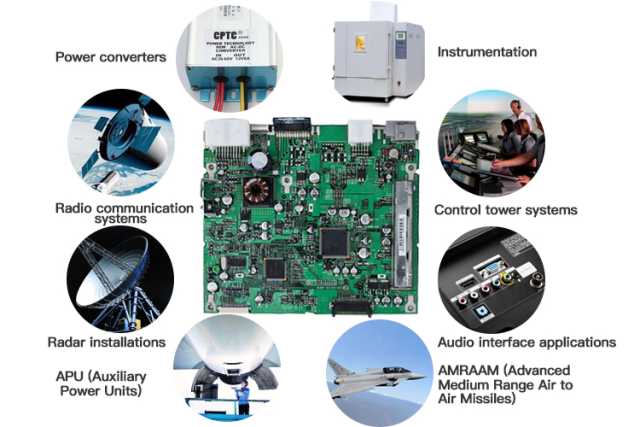

3. Aerospace and Satellite Communication Systems

RO4835’s low moisture absorption (<0.1%) and thermal endurance make it ideal for satellite payloads and LNB modules.

It maintains impedance control in low-pressure, high-radiation environments, ensuring signal clarity and minimal power loss.

Hybrid Stackups with RO4835: Balancing Performance and Cost

In practical manufacturing, few RF systems use pure RO4835 across the full stackup.

To balance performance and cost, engineers often combine RO4835 with FR-4 or low-Dk prepregs, forming hybrid PCBs.

Such designs use RO4835 only on RF-critical layers, while inner layers manage power, control, and digital routing.

However, this approach introduces CTE mismatch, resin compatibility, and lamination challenges, requiring precise process control.

KKPCB’s Hybrid Lamination Expertise:

-

Vacuum-assisted lamination with < 2°C/min heating ramp

-

Balanced press layup to minimize warpage

-

Plasma and micro-etch activation for strong adhesion

-

Impedance verification up to 110 GHz

This ensures stable impedance, tight dielectric control, and repeatable mass production for hybrid builds.

Reliability Testing and Long-Term Stability

KKPCB conducts full RF reliability evaluation on RO4835 PCBs to ensure material consistency in production:

-

Thermal cycling: –40°C to +150°C, 1,000 cycles

-

Moisture resistance: 85°C / 85% RH, 1000 hr

-

Solder float: 288°C × 10 sec × 3 cycles

-

Impedance validation: ±5 µm tolerance, up to 77 GHz

After reliability testing, KKPCB’s results show <0.5% dielectric drift and zero delamination, confirming RO4835’s suitability for long-term field deployment.

KKPCB Engineering Support for RO4835 PCB Manufacturing

KKPCB provides comprehensive material and process support for RF, 5G, and radar system PCBs using RO4835:

-

Stackup simulation and impedance modeling

-

Rogers material validation and lamination tuning

-

RF impedance measurement up to 110 GHz

-

IPC Class 3 / IATF 16949 certified production lines

By integrating advanced process control and RF testing, KKPCB ensures every RO4835-based PCB meets both design intent and reliability expectations for critical applications.

Conclusion: Why RO4835 Is the Future of High-Frequency Reliability

As RF design pushes into higher frequencies and harsher environments, Rogers RO4835 stands out for its thermal endurance, low loss, and oxidation stability.

With KKPCB’s hybrid lamination process, OEMs can bridge the gap between lab-grade performance and mass production reliability, enabling stable 5G, radar, and satellite communication systems.

Contact KKPCB RF Engineering Team

To discuss your RO4835 PCB design, or request a stackup and lamination review, reach out to KKPCB’s engineering experts for data-driven DFM support and reliability consultation.