What Is a UAV PCB?

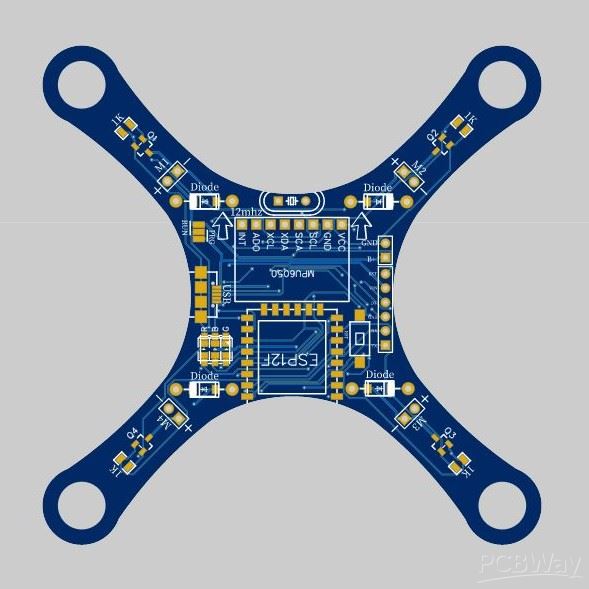

A UAV PCB is a specially designed printed circuit board optimized for unmanned aerial vehicles and drones, where weight, signal integrity, high-frequency communication, and thermal reliability are critical.

UAV PCBs integrate sensor modules, RF communication circuits, power management, and control systems into compact, high-density layouts suitable for aerial applications.

Key Features of UAV PCB

High-performance UAV PCBs typically include:

-

Lightweight and compact multilayer design

-

High-frequency performance for RF telemetry and communication

-

Impedance controlled PCB traces for high-speed digital signals

-

Thermal management for power modules and processors

-

Vibration and shock-resistant structure for aerial environments

These features ensure reliable flight performance and mission-critical operations.

Material Selection for UAV PCB

Material choice is crucial for UAV PCB reliability and performance:

-

Low-loss laminates (RO4350B, RF-35) – For RF communication and high-frequency sensor modules

-

High-speed laminates (Megtron 7, Megtron 6) – For high-speed data buses and processor connections

-

Lightweight FR-4 hybrids – Cost-effective and weight-optimized layers

-

Alumina or ceramic options – For high-power or high-thermal stress modules

Proper material selection ensures signal integrity, thermal stability, and minimal weight.

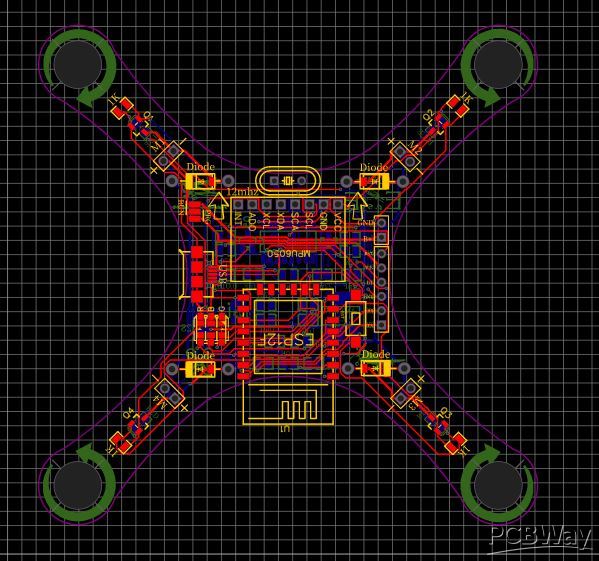

Design Considerations for UAV PCB

UAV PCB design requires careful attention to:

-

Stack-up optimization for signal, power, and ground layers

-

Impedance controlled traces for high-speed and RF signals

-

Multilayer routing with blind/buried vias for dense layouts

-

Thermal paths and heat dissipation for onboard processors

-

Vibration and shock resistance for airborne reliability

Correct design ensures mission-critical reliability and high-frequency performance.

Manufacturing Requirements for UAV PCB

Producing reliable UAV PCBs involves:

-

High-precision multilayer lamination and via formation

-

Tight impedance and thickness tolerance control

-

Advanced plating, etching, and surface finishing

-

Electrical testing for RF, high-speed signals, and thermal performance

-

Compliance with aerospace and industrial quality standards

Experienced manufacturers ensure UAV PCBs meet aerial system reliability and safety requirements.

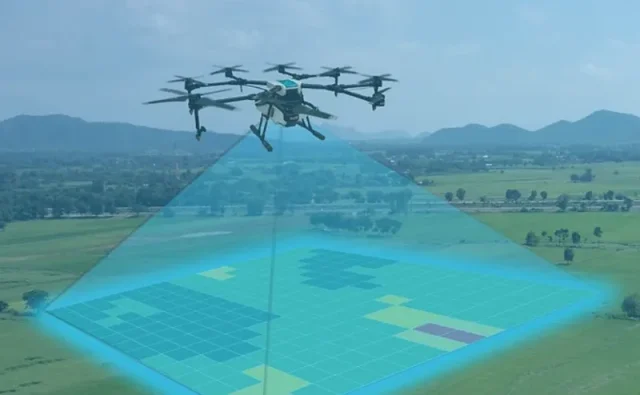

Applications of UAV PCB

UAV PCBs are widely used in:

-

Commercial drones and UAV platforms

-

Autonomous delivery systems

-

Aerial mapping and imaging systems

-

Military and surveillance UAVs

-

Industrial inspection drones

-

High-frequency telemetry and RF communication modules

They are critical wherever lightweight, high-performance, and reliable PCBs are required for airborne systems.

Conclusion

A UAV PCB provides the backbone for high-performance, lightweight, and reliable unmanned aerial systems. Through careful material selection, multilayer and impedance-controlled design, and precise manufacturing, UAV PCBs ensure stable operation in demanding aerial environments.

Partnering with an experienced UAV PCB manufacturer guarantees consistent quality, signal integrity, and reliable performance from prototype to mass production.