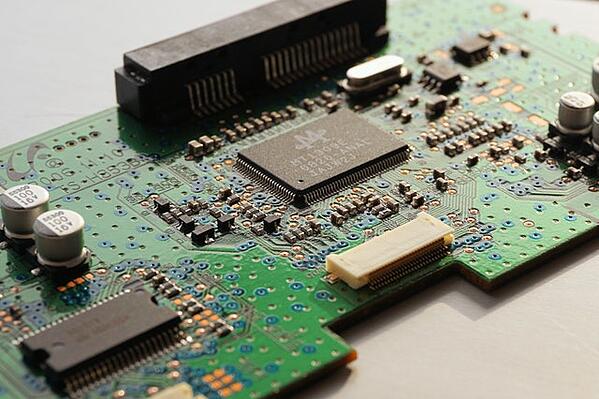

In modern semiconductor testing, the Test Socket PCB for IC is a critical interface between the device under test (DUT) and Automated Test Equipment (ATE). These PCBs enable accurate electrical contact, high-speed signal transmission, and mechanical stability, ensuring reliable IC, memory, and RF testing.

As integrated circuits become more complex with higher pin counts, finer pitch, and faster data rates, the role of the test socket PCB has become increasingly important. A high-quality Test Socket PCB for IC ensures repeatable test results, signal integrity, and long-term durability, directly impacting test yield and semiconductor production efficiency.

Key Features of Test Socket PCBs for ICs

-

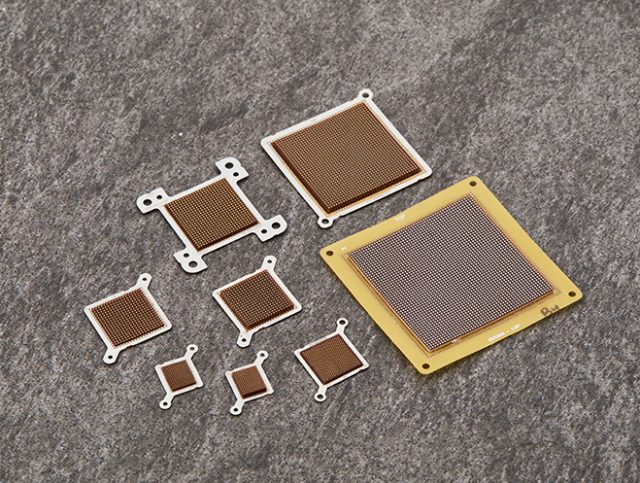

High-Density and High Pin Count Design

Supports ICs with hundreds or thousands of pins, using fine-line routing and HDI technology to maintain signal integrity. -

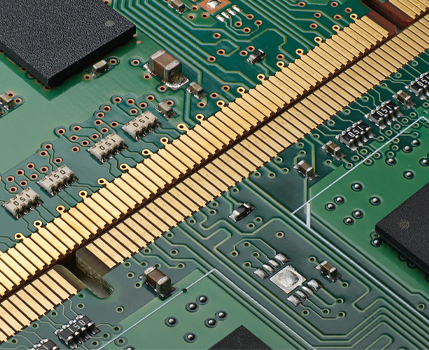

Controlled Impedance for High-Speed Signals

Ensures accurate digital, analog, and RF testing by minimizing crosstalk, signal reflections, and timing errors. -

Mechanical Precision and Reliability

Maintains consistent probe alignment and contact force across thousands of test cycles, reducing failure risks. -

Multilayer and Rigid-Flex PCB Options

Optimized stackups separate signal, power, and ground planes to improve isolation and reduce noise. -

Low-Loss Materials for High-Frequency Testing

Using low Dk/Df laminates ensures signal integrity for high-speed, RF, and microwave ICs.

Applications of Test Socket PCBs

Test Socket PCBs for ICs are used in:

-

IC functional and parametric testing

-

Memory module testing (DRAM, SRAM, Flash)

-

RF and microwave IC testing

-

Wafer-level probing and final package validation

-

Automotive, IoT, and high-speed semiconductor validation

These applications demand high accuracy, stable impedance, and mechanical reliability, all provided by precision test socket PCBs.

Choosing a Test Socket PCB Manufacturer

A professional test socket PCB manufacturer should offer:

-

Expertise in high-pin-count, HDI, and multilayer PCB fabrication

-

Experience with controlled impedance, low-loss materials, and RF/microwave testing

-

Support for prototype, small-batch, and mass production

-

Quality control and electrical testing capabilities to ensure repeatable test results

Partnering with a skilled manufacturer reduces test errors, accelerates validation, and improves semiconductor yield.

Conclusion

Test Socket PCBs for ICs are an indispensable component of modern semiconductor testing, providing high-density routing, controlled impedance, mechanical precision, and low-loss signal paths. From memory modules to RF ICs, high-quality test socket PCBs ensure accurate, repeatable, and reliable testing, supporting efficient semiconductor development and mass production.