Millimeter-wave (mmWave) technologies are rapidly expanding in applications such as 5G, automotive radar, satellite communication, and advanced sensing systems. At these extremely high frequencies, PCB material selection becomes critical. Taconic RF-35 PCB for mmWave applications is widely recognized for its low loss, stable dielectric properties, and excellent manufacturing reliability.

This article explores why Taconic RF-35 is a strong material choice for mmWave PCB designs and what engineers should consider during fabrication.

What Is Taconic RF-35 PCB Material?

Taconic RF-35 is a woven glass reinforced, ceramic-filled hydrocarbon laminate designed for high-frequency and microwave circuits. It combines low dielectric loss with mechanical stability, making it suitable for demanding mmWave environments.

Key properties of Taconic RF-35 include:

-

Dielectric constant (Dk) ≈ 3.5

-

Low dissipation factor (Df ≈ 0.0018)

-

Excellent dimensional stability

-

Consistent electrical performance across wide frequency ranges

These characteristics make Taconic RF-35 PCB material ideal for mmWave signal transmission.

Why Taconic RF-35 PCB Is Ideal for mmWave Applications

At mmWave frequencies, even small dielectric variations can significantly affect performance. Taconic RF-35 PCB for mmWave designs offers several advantages:

-

Low Signal Loss: Low Df reduces insertion loss at millimeter-wave frequencies

-

Stable Dielectric Properties: Maintains consistent impedance and phase stability

-

High-Frequency Reliability: Performs well in GHz and mmWave bands

-

Manufacturing Compatibility: Easier to process compared with traditional PTFE materials

These benefits support high-efficiency mmWave circuit and antenna performance.

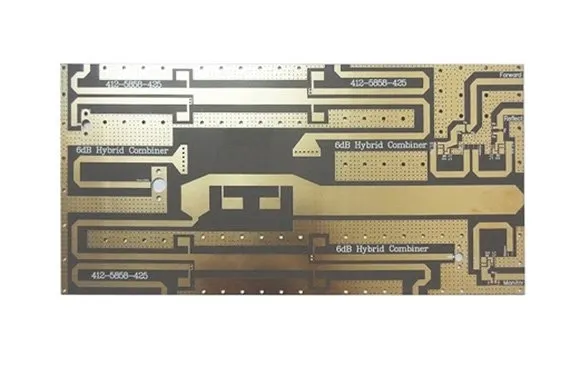

Impedance Control and Stack-Up Design

Precise impedance control is critical for mmWave PCB performance.

When designing with Taconic RF-35:

-

Trace geometry and dielectric thickness must be tightly controlled

-

Copper roughness and surface finish affect loss at mmWave frequencies

-

Hybrid stackups may combine RF-35 with FR-4 or other materials for cost and mechanical balance

Proper stack-up design ensures predictable impedance and stable mmWave performance.

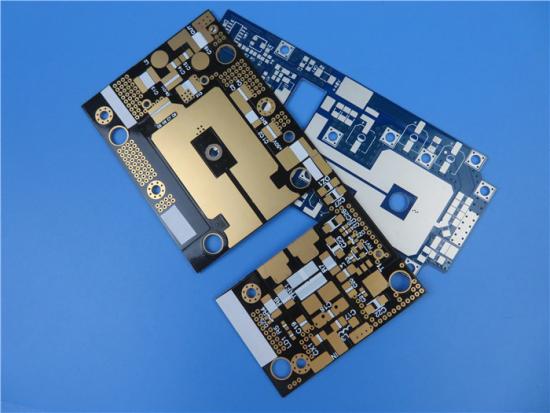

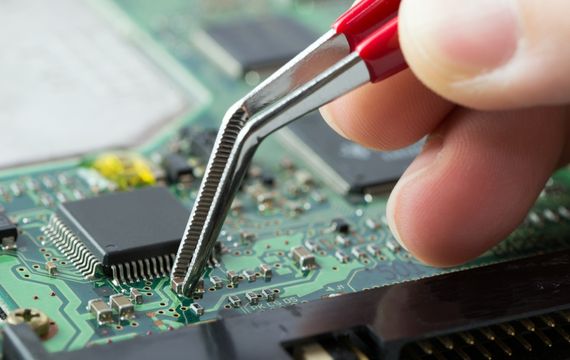

Manufacturing Considerations for Taconic RF-35 PCBs

Producing Taconic RF-35 PCBs for mmWave requires specialized manufacturing expertise, including:

-

High-precision lamination and etching

-

Tight control of line width, spacing, and dielectric thickness

-

RF-specific testing such as TDR and insertion loss measurement

-

Strict quality control from prototype to mass production

Experienced high-frequency PCB manufacturers can fully leverage the material’s electrical advantages.

Applications of Taconic RF-35 PCB in mmWave Systems

Taconic RF-35 PCBs are widely used in:

-

5G mmWave antennas and modules

-

Automotive radar (24 GHz, 77 GHz)

-

Satellite and aerospace communication systems

-

mmWave sensors and imaging equipment

-

High-frequency RF front-end modules

These applications demand low loss, stable impedance, and reliable long-term performance.

Conclusion

Taconic RF-35 PCB for mmWave applications offers an excellent combination of low loss, dielectric stability, and manufacturability. Its performance characteristics make it a strong alternative to PTFE-based materials for high-frequency and mmWave designs.

By working with an experienced RF and mmWave PCB manufacturer, engineers can achieve precise impedance control, consistent quality, and reliable performance for advanced millimeter-wave applications.