As millimeter-wave (mmWave) technology becomes essential for 5G, automotive radar, and high-speed wireless systems, the selection of PCB materials plays a critical role in overall RF performance. Taconic RF-35 PCB for mmWave applications is a proven solution designed to deliver low loss, stable dielectric properties, and consistent performance at extremely high frequencies.

Compared with conventional PCB laminates, Taconic RF-35 offers excellent electrical stability, making it well-suited for demanding mmWave circuit designs.

Overview of Taconic RF-35 PCB Material

Taconic RF-35 PCB is based on a glass-reinforced PTFE composite material engineered for RF and microwave applications. Its key electrical properties include:

-

Dielectric constant (Dk) ≈ 3.5

-

Very low dissipation factor (Df ≈ 0.0018 @ 10 GHz)

-

Excellent thermal stability

-

Low moisture absorption for consistent RF behavior

These properties make Taconic RF-35 PCB for mmWave designs highly reliable and repeatable.

Why Choose Taconic RF-35 PCB for mmWave Designs?

Ultra-Low Signal Loss

Low dielectric loss minimizes insertion loss, which is critical at mmWave frequencies where attenuation increases rapidly.

Stable Dielectric Constant

A stable Dk ensures predictable impedance and phase consistency across wide mmWave frequency ranges.

High-Frequency Impedance Accuracy

Taconic RF-35 PCB supports precise controlled impedance structures, reducing reflection loss and signal distortion.

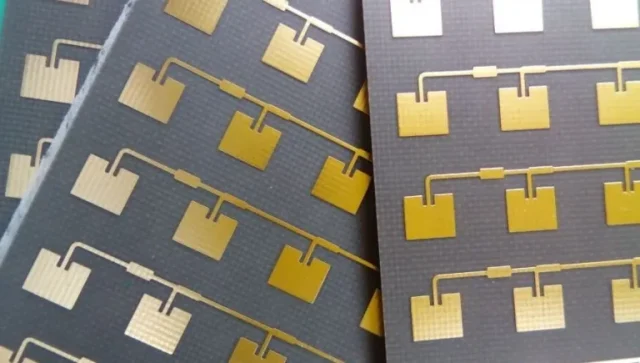

Suitable for Advanced RF Structures

The material performs well in microstrip, stripline, and grounded coplanar waveguide (GCPW) structures commonly used in mmWave circuits.

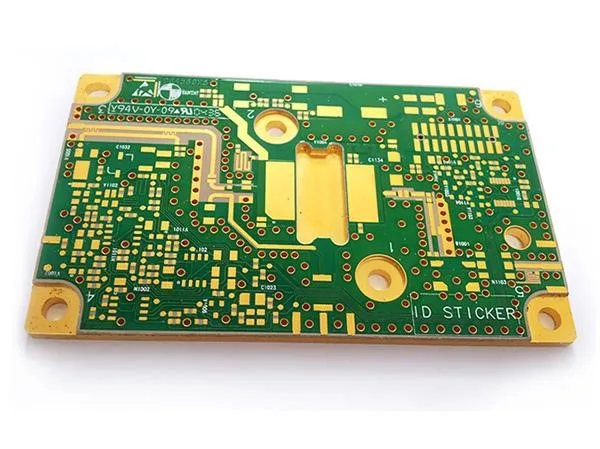

Controlled Impedance Manufacturing for Taconic RF-35 PCB

Manufacturing Taconic RF-35 PCB for mmWave applications requires specialized RF process control, including:

-

Accurate stackup design and impedance simulation

-

Tight control of dielectric thickness and copper roughness

-

Precision etching for fine-line RF traces

-

TDR testing and impedance verification

These controls ensure stable mmWave signal transmission and repeatable performance.

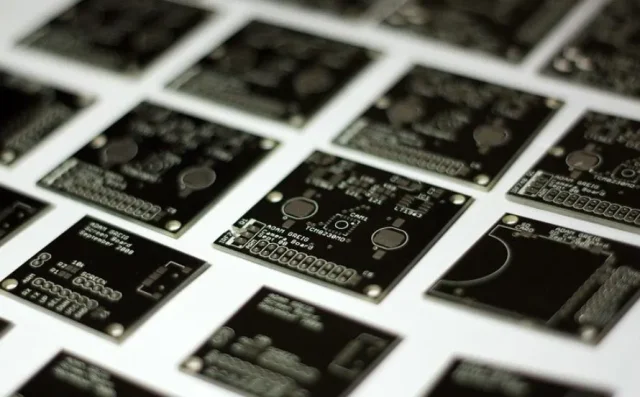

Taconic RF-35 PCB Stackup Options for mmWave

Common Taconic RF-35 PCB stackups include:

-

Single-layer and double-layer RF-35 PCBs

-

Multilayer RF-35 PCBs with dedicated ground planes

-

Hybrid stackups combining RF-35 with FR-4 or other materials for cost optimization

Hybrid RF-35 designs are often used in mmWave RF front-end modules.

Manufacturing Considerations for Taconic RF-35 PCB

Producing high-quality Taconic RF-35 PCB for mmWave applications requires:

-

Fine-line pattern control for mmWave geometries

-

Copper surface roughness optimization to reduce conductor loss

-

High-precision drilling and reliable via metallization

-

Strict AOI, electrical testing, and RF inspection

An experienced RF PCB manufacturer is essential to ensure consistency and yield.

Applications of Taconic RF-35 PCB in mmWave Systems

Taconic RF-35 PCBs are widely used in:

-

mmWave 5G antenna and RF modules

-

Automotive radar systems

-

High-frequency point-to-point communication

-

Advanced RF front-end and phased-array systems

These applications require ultra-low loss and stable RF performance.

Choosing a Manufacturer for Taconic RF-35 PCB for mmWave

When sourcing Taconic RF-35 PCB for mmWave, consider:

-

Experience with PTFE-based RF materials

-

Controlled impedance and mmWave testing capability

-

Support for prototype and volume production

-

Engineering expertise in high-frequency PCB design

The right manufacturing partner ensures stable mmWave performance and scalable production.

Conclusion

Taconic RF-35 PCB for mmWave applications offers ultra-low loss, stable dielectric properties, and excellent performance at high frequencies. With precise impedance control and RF-focused manufacturing, RF-35 PCBs enable reliable and high-performance mmWave circuit designs.

Partnering with an experienced RF PCB manufacturer ensures your Taconic RF-35 PCB projects meet both technical and production requirements.