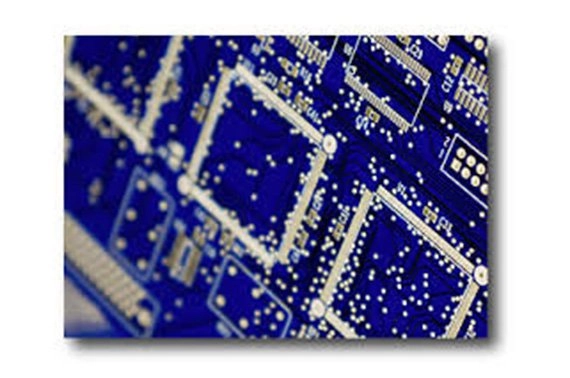

Taconic PCB materials are a class of engineered laminates specifically designed to address the challenges posed by high-frequency RF circuits, microwave systems, and high-speed digital signals. As system frequencies extend into multi-gigahertz and mmWave bands, dielectric loss, impedance variation, and phase instability become dominant constraints. Taconic PCB materials help engineers manage these constraints by delivering a stable dielectric environment, low dissipation factor, and predictable high-frequency behavior.

Material Properties That Define Taconic PCB Performance

At the core of Taconic PCB technology is a material system engineered for low dielectric loss and stable dielectric constant (Dk). These properties directly influence how an electromagnetic wave propagates through the PCB substrate:

-

Low dissipation factor (Df) minimizes dielectric loss at high frequencies, preserving signal amplitude across trace lengths.

-

Stable dielectric constant reduces impedance drift over frequency and temperature, supporting consistent controlled impedance routing.

-

Low dielectric anisotropy mitigates signal distortion in differential and microstrip/stripline structures.

-

Thermal stability and moisture resistance ensure performance consistency in diverse environmental conditions.

These characteristics make Taconic materials a preferred choice for RF and microwave designs where standard FR-4 laminates introduce unacceptable performance degradation.

Impact on Signal Integrity and Impedance Control

Signal integrity in high-frequency circuits depends heavily on material behavior. Taconic PCBs enable tighter control over impedance and transmission line effects:

-

Reduced insertion loss due to lower dielectric attenuation

-

Lower return loss and better VSWR (Voltage Standing Wave Ratio) in RF paths

-

Predictable phase response across frequency bands

-

Improved match between simulation and measured results

Because high-speed and RF systems often rely on controlled impedance lines (e.g., 50Ω single-ended, 90Ω or 100Ω differential), Taconic PCB materials make it possible to meet design targets with tighter tolerances than general-purpose laminates.

Thermal and Mechanical Considerations

While electrical performance is paramount, Taconic materials also exhibit desirable thermal and mechanical behavior:

-

High Tg (glass transition temperature) supports stable performance under reflow and thermal cycling.

-

Low moisture absorption prevents dielectric constant shifts in humid environments.

-

CTE (coefficient of thermal expansion) characteristics compatible with plated copper and component materials help reduce mechanical stress and solder joint fatigue.

These thermal-mechanical properties ensure that Taconic PCBs remain dimensionally stable and electrically reliable throughout both assembly and field operation.

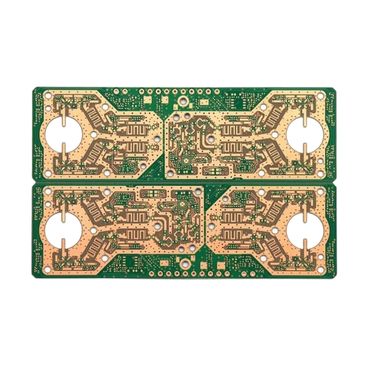

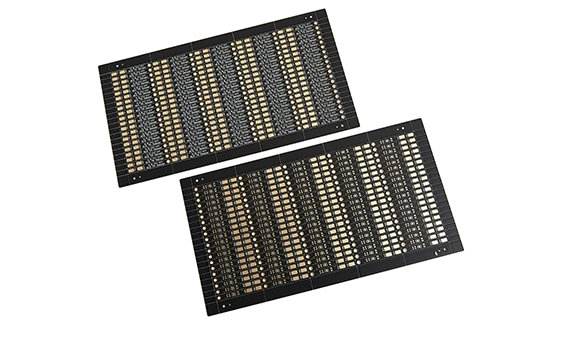

Manufacturing Implications

Fabricating Taconic PCB assemblies involves process considerations different from standard epoxy-based boards:

-

Precision drilling and plating to accommodate fine-line features typical of high-speed and RF layer stacks

-

Controlled lamination profiles to maintain consistent dielectric thickness and stackup integrity

-

Tight etch control for transmission lines where trace width modulation directly affects impedance

-

Comprehensive post-fabrication electrical validation, including TDR (Time Domain Reflectometry) for impedance verification

Manufacturers must integrate these controls into their process flows to fully leverage Taconic PCB materials.

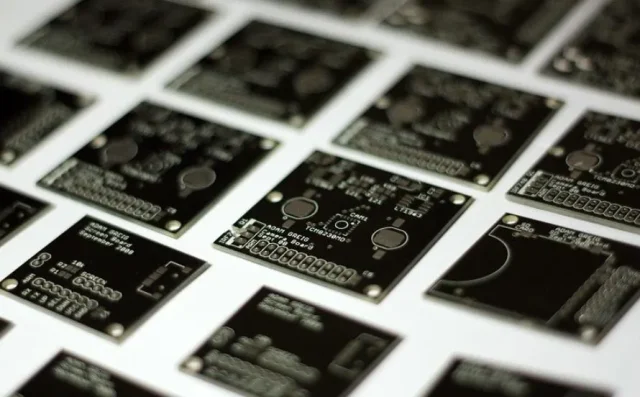

Typical Applications

Taconic PCBs are widely used in systems that require controlled high-frequency performance and electrical precision, including:

-

5G NR and mmWave communication hardware

-

Satellite and aerospace RF modules

-

Radar and electronic warfare systems

-

High-speed communication backplanes

-

RF front-end and intermediate frequency (IF) subsystems

-

Test and measurement equipment in GHz ranges

In such applications, Taconic PCB materials contribute directly to system-level signal integrity, channel performance, and operational reliability.

Engineering Perspective

From an engineering standpoint, Taconic PCB materials are not simply an upgraded substrate—they are a design variable that directly influences high-frequency signal behavior. Proper material selection, stackup planning, and manufacturing discipline help engineers meet both electrical and mechanical targets in advanced electronic systems.

KKPCB supports Taconic PCB projects through material guidance, controlled impedance stackup design, and precision fabrication workflows, ensuring that your high-frequency and high-speed designs perform as intended from prototype through production.