What Is a Smart Factory PCB?

A Smart Factory PCB is a specialized printed circuit board used in smart manufacturing, industrial automation, and Industry 4.0 systems. These PCBs serve as the backbone of intelligent factories, enabling real-time data acquisition, automated control, machine connectivity, and predictive maintenance.

Smart factory PCBs must operate reliably in harsh industrial environments while supporting high-speed communication and precise control.

Key Requirements for Smart Factory PCB

Smart factory PCBs must meet strict industrial requirements:

-

High reliability for 24/7 operation

-

Resistance to vibration, dust, and temperature variation

-

Stable power delivery for industrial controllers

-

Impedance controlled signal paths for data communication

-

Strong EMI and noise immunity

-

Long product lifecycle support

These requirements ensure stable factory operation and minimal downtime.

Materials Used in Smart Factory PCB

Material selection is critical for smart factory PCB performance:

-

High-Tg FR-4 for industrial control boards

-

Heavy copper PCB structures for power distribution

-

Low-loss materials for industrial Ethernet and communication modules

-

Ceramic or Alumina PCB for high-temperature or high-power sections

-

Hybrid PCB materials combining control, power, and communication layers

The right material ensures durability and electrical stability.

Design Considerations for Smart Factory PCB

Designing a smart factory PCB requires industrial-level expertise:

-

Multilayer PCB stack-up for control, power, and signal separation

-

Robust grounding and EMI shielding design

-

Thermal management for power and control ICs

-

HDI structures for compact smart modules

-

High-voltage isolation and safety spacing

-

Design for manufacturability (DFM) and long-term maintenance

Good design directly impacts system uptime and reliability.

Manufacturing Challenges of Smart Factory PCB

Manufacturing smart factory PCBs involves:

-

Precision multilayer lamination

-

Consistent copper thickness and trace control

-

Industrial-grade surface finishes (ENIG, Immersion Silver, HASL)

-

Strict electrical testing and reliability inspection

-

Process traceability for long-term supply stability

Experienced manufacturers ensure consistent quality across production batches.

Applications of Smart Factory PCB

Smart factory PCBs are widely used in:

-

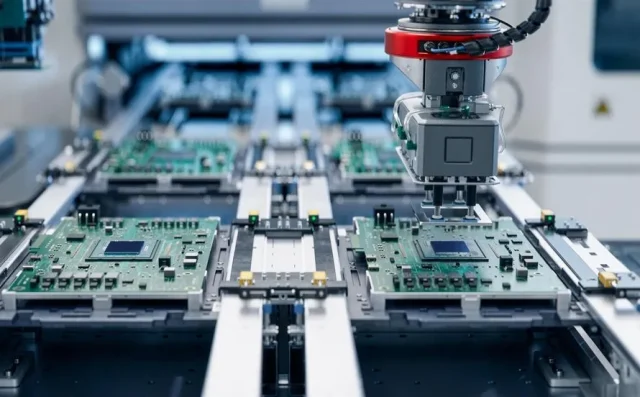

Industrial automation control systems

-

PLC and motion control modules

-

Robotics and robotic production lines

-

Industrial IoT (IIoT) gateways

-

Smart sensors and monitoring devices

-

Predictive maintenance and data acquisition systems

They are essential for modern intelligent factories.

Conclusion

A Smart Factory PCB is a key enabler of Industry 4.0 and intelligent manufacturing, providing reliable electrical performance, robust mechanical design, and long-term stability. Through proper material selection, optimized design, and advanced manufacturing, smart factory PCBs support efficient, automated, and connected production environments.

Partnering with an experienced Smart Factory PCB manufacturer ensures consistent quality, reliable delivery, and scalable solutions from prototype to mass production.