As global manufacturing transitions into fully connected, autonomous, data-driven ecosystems, the Smart Factory PCB has become the central hardware platform enabling real-time monitoring, predictive analytics, robotic coordination, and closed-loop industrial automation. Every intelligent machine, from PLC control modules to AMR robots and sensor gateways, relies on a high-reliability Smart Factory PCB to operate with precision and consistency.

In a Smart Factory, the PCB is no longer a passive interconnect medium—it is a high-performance computing, sensing, and communication platform engineered to support Industry 4.0 and future Industry 5.0 demands.

1. Engineering Requirements for a Smart Factory PCB

The Smart Factory PCB must perform reliably under harsh industrial conditions while supporting:

-

24/7 operation

-

Microsecond-level control loops

-

High-speed data exchange

-

Predictive-maintenance sensing

-

Distributed IIoT architectures

-

Real-time decision-making via edge AI

This demands advanced PCB engineering far beyond standard industrial design.

2. High-Speed Industrial Communication Integration

A Smart Factory relies on deterministic and low-latency communication.

A well-designed Smart Factory PCB integrates:

-

Gigabit Industrial Ethernet

-

EtherCAT for synchronized motion control

-

CAN / CAN-FD for robotics and AGVs

-

RS-485 / Modbus for legacy equipment

-

Sub-GHz or industrial Wi-Fi IIoT modules

-

Edge-to-cloud secure communication interfaces

These communication layers require:

-

Strict impedance control

-

Crosstalk mitigation through optimized spacing

-

Ground isolation for noise-heavy environments

-

Precise differential pair matching

A Smart Factory PCB with poor SI/PI performance will compromise the entire production line.

3. Sensor Fusion and Real-Time Data Acquisition

A key function of the Smart Factory PCB is to interface with diverse industrial sensors:

-

Current, voltage, and torque feedback

-

Temperature, pressure, and vibration sensors

-

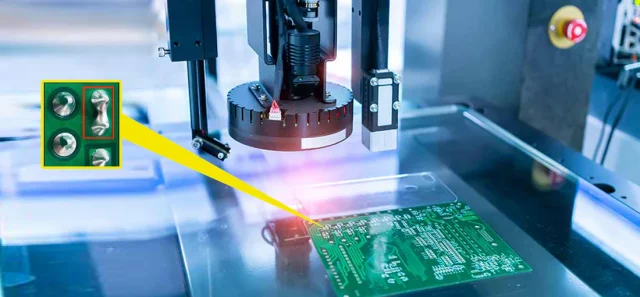

Laser/optical inspection modules

-

Machine vision cameras

-

Safety and proximity detection sensors

To ensure accurate sensing, the Smart Factory PCB must include:

-

Low-noise analog signal chains

-

Shielded routing for high-resolution ADCs

-

EMI-filtered sensor inputs

-

Precision timing and synchronization hardware

Sensor integrity directly affects predictive maintenance and automated process optimization.

4. Edge Computing and Embedded AI Acceleration

Modern smart factories require decentralized intelligence.

Thus, the Smart Factory PCB often integrates:

-

High-performance MCU/MPU platforms

-

FPGA logic for deterministic real-time control

-

Neural network accelerators for on-board AI inference

-

Dedicated memory subsystems for edge analytics

-

Secure hardware modules for OT cybersecurity

This allows equipment to process data locally, reducing latency and improving system autonomy.

5. Power Integrity, Industrial Safety, and Redundancy

A Smart Factory PCB must maintain stable operation despite power disturbances, electromagnetic noise, and heavy motor loads.

Necessary engineering features include:

-

Thick copper planes for high-current reliability

-

Transient suppression and surge protection

-

Galvanic isolation between control and power stages

-

Redundant power domains for safety-critical systems

-

Hardware watchdogs and fault-detection circuits

Industrial uptime is directly tied to PCB power integrity and protection design.

6. Material Selection and Multilayer Stackup Engineering

Material choice defines the high-frequency and thermal behavior of a Smart Factory PCB:

-

High-Tg FR-4 for general industrial reliability

-

PTFE/Rogers materials for high-speed networking

-

Metal-core/IMS for power modules

-

Ceramic PCB for extreme thermal cycling

Multilayer stackup strategies ensure:

-

Controlled impedance for communication layers

-

Isolated planes for analog precision circuits

-

Robust thermal dissipation

-

Mechanical strength against vibration/shock

Typical Smart Factory PCB stackups range from 6 to 14 layers depending on complexity.

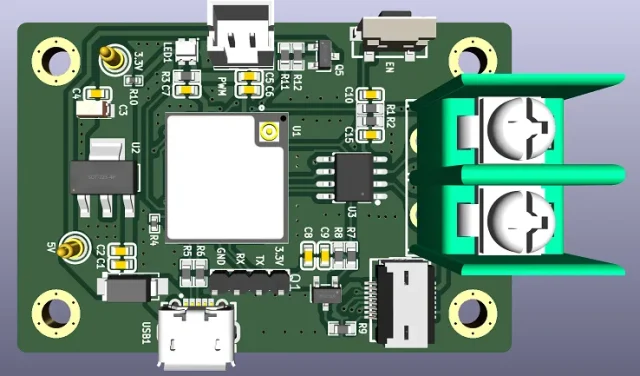

7. KKPCB Case Study — High-Performance Smart Factory PCB

KKPCB engineered a 10-layer

As global manufacturing transitions into fully connected, autonomous, data-driven ecosystems, the Smart Factory PCB has become the central hardware platform enabling real-time monitoring, predictive analytics, robotic coordination, and closed-loop industrial automation. Every intelligent machine, from PLC control modules to AMR robots and sensor gateways, relies on a high-reliability Smart Factory PCB to operate with precision and consistency.

In a Smart Factory, the PCB is no longer a passive interconnect medium—it is a high-performance computing, sensing, and communication platform engineered to support Industry 4.0 and future Industry 5.0 demands.

Engineering Summary

The Smart Factory PCB is the technological foundation of modern intelligent manufacturing. It enables:

-

High-speed industrial communication

-

Real-time automation

-

Advanced sensing and predictive maintenance

-

Edge computing and AI inference

-

Robotics and autonomous system coordination

-

Long-term industrial reliability

As factories evolve toward full autonomy and hyperconnectivity, the engineering quality of the Smart Factory PCB determines system intelligence, efficiency, and competitive advantage.