Between prototype validation and mass production, test engineers require repeatable manufacturing that reflects real production conditions. Small Batch ATE PCB manufacturing delivers controlled, low-volume builds that ensure electrical consistency, mechanical reliability, and scalable processes for automated test equipment.

Small batch ATE PCBs are essential for system qualification and risk reduction.

What Defines a Small Batch ATE PCB?

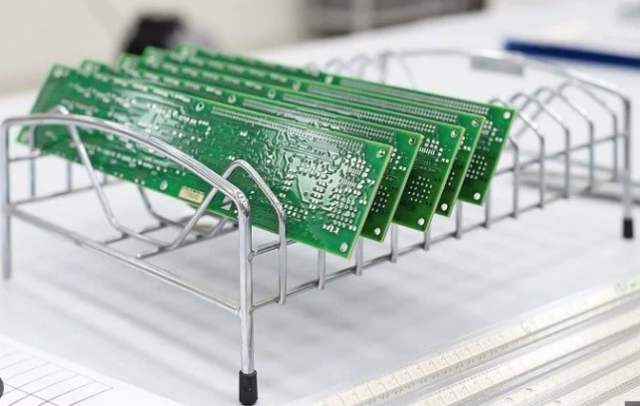

A Small Batch ATE PCB typically refers to low-volume production runs—often from tens to a few hundred boards—used for engineering qualification, system verification, and pre-production testing.

Unlike single prototypes, small batch builds focus on process stability and board-to-board consistency.

Why Small Batch Manufacturing Is Critical for ATE

Small batch ATE PCB manufacturing allows teams to:

-

Validate repeatability across multiple units

-

Evaluate yield and assembly stability

-

Detect design or process issues before scaling

This stage significantly reduces downstream risk.

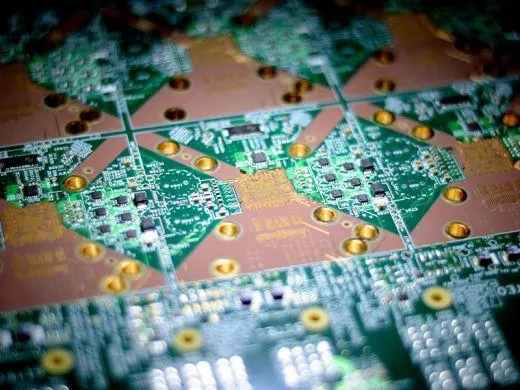

Electrical Consistency and Signal Integrity

ATE systems depend on predictable signal behavior. Small batch ATE PCBs emphasize:

-

Controlled impedance across all test channels

-

Stable multilayer stackups and material control

-

Repeatable signal routing geometry

Consistent electrical performance ensures reliable test results.

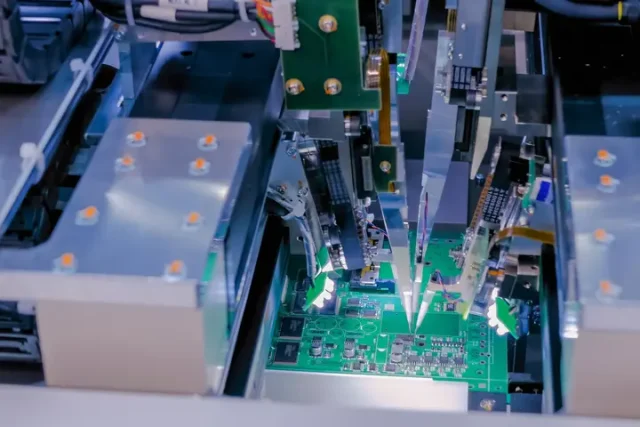

Power Integrity and Thermal Evaluation

Small batch ATE PCB builds enable engineers to:

-

Validate power distribution under load

-

Observe thermal behavior over extended test cycles

-

Optimize decoupling and grounding strategies

These insights are critical for long-term operation.

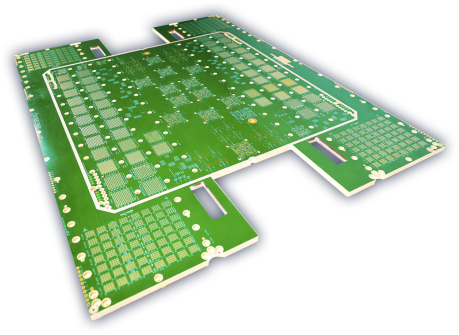

Manufacturing Process Validation

Small batch ATE PCB production verifies:

-

Fabrication repeatability

-

Assembly accuracy for high pin count components

-

Connector, socket, and interface reliability

Process validation ensures readiness for volume production.

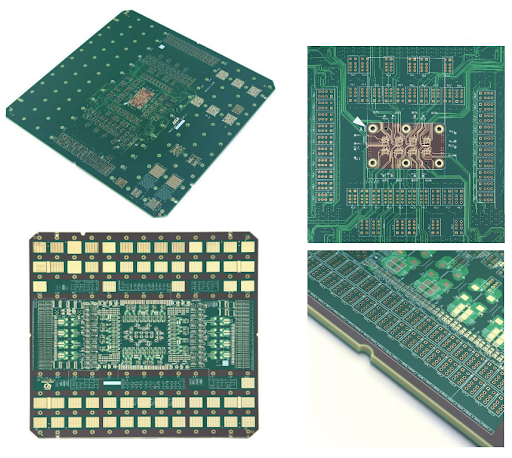

Design-for-Test and Debug Accessibility

Small batch ATE PCBs are optimized for engineering use with:

-

Accessible probing points

-

Clear reference labeling

-

Modular layout concepts

These features support efficient troubleshooting.

Typical Applications of Small Batch ATE PCBs

Small batch ATE PCBs are widely used in:

-

ATE system qualification builds

-

Semiconductor device validation

-

Customer and regulatory certification testing

-

Pilot production test environments

Each application benefits from controlled low-volume manufacturing.

Transition from Small Batch to Volume Production

An effective small batch ATE PCB strategy ensures:

-

Minimal design changes during scale-up

-

Stable electrical and mechanical performance

-

Predictable cost and lead time

This enables a smooth transition to mass production.

Choosing a Small Batch ATE PCB Manufacturer

When selecting a small batch ATE PCB supplier, key factors include:

-

Experience with test and semiconductor PCBs

-

Controlled impedance and multilayer capability

-

Strong DFM and engineering feedback

-

Flexible scheduling and fast turnaround

A capable partner supports both qualification and production goals.

Conclusion

Small Batch ATE PCB manufacturing is a critical step in qualifying automated test equipment. By combining low-volume flexibility with production-level consistency, small batch ATE PCBs enable confident validation, reduced risk, and efficient scale-up.

Partnering with an experienced small batch ATE PCB manufacturer ensures reliable performance from qualification to mass production.