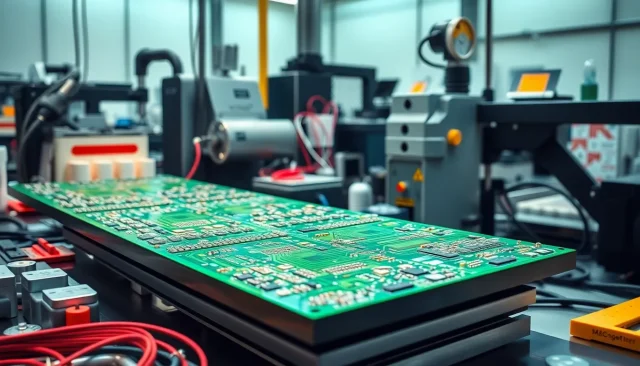

Between prototyping and mass production, semiconductor test development requires a flexible manufacturing stage to validate design stability and manufacturing consistency. Small batch ATE PCBs bridge this critical gap by enabling controlled, repeatable builds for engineering validation and pilot testing in ATE environments.

Small batch ATE PCB manufacturing ensures design maturity before full-scale production.

What Is a Small Batch ATE PCB?

A Small Batch ATE PCB refers to ATE test boards manufactured in limited quantities, typically ranging from a few units to several dozen boards. These builds are used to:

-

Validate electrical and mechanical consistency

-

Evaluate manufacturing yield

-

Confirm long-term reliability in test environments

Small batch ATE PCBs closely reflect production conditions.

Why Small Batch Manufacturing Matters for ATE

ATE systems demand consistency. Small batch ATE PCB manufacturing allows engineers to:

-

Verify repeatability across multiple boards

-

Detect process-related variations early

-

Optimize stackup, materials, and routing

-

Reduce risks before mass production

This stage is essential for stable test deployment.

Key Design and Manufacturing Features

High-quality Small Batch ATE PCBs include:

-

Multilayer stackups with controlled impedance

-

Support for high pin count devices and sockets

-

Stable power distribution and grounding

-

Tight process control during fabrication

These features ensure consistent test performance across the batch.

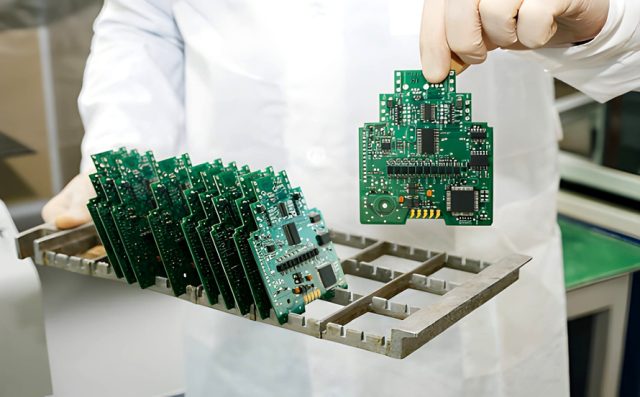

Transition from Prototype to Production

Small batch ATE PCBs serve as a stepping stone between prototype and volume manufacturing. They help:

-

Finalize PCB design and BOM

-

Validate assembly and testing procedures

-

Establish baseline manufacturing quality

This transition reduces unexpected issues during mass production.

Applications of Small Batch ATE PCBs

Small batch ATE PCBs are widely used in:

-

Semiconductor IC functional testing

-

Load boards and interface boards

-

High-speed and mixed-signal test platforms

-

Reliability and stress testing

Each application benefits from consistent, production-like builds.

Selecting a Small Batch ATE PCB Manufacturer

When choosing a Small Batch ATE PCB supplier, key considerations include:

-

Experience with ATE and semiconductor testing

-

Capability for controlled impedance and multilayer PCBs

-

Stable manufacturing processes and quality control

-

Flexibility to scale from small batch to volume

A capable partner supports long-term test system deployment.

Conclusion

Small Batch ATE PCBs are a critical stage in semiconductor test development, enabling engineers to validate consistency, reliability, and manufacturability. By bridging the gap between prototyping and mass production, small batch ATE PCB manufacturing reduces risk and ensures stable test performance.

Partnering with an experienced Small Batch ATE PCB manufacturer ensures a smooth transition to full-scale production.