What Is RO4350B PCB?

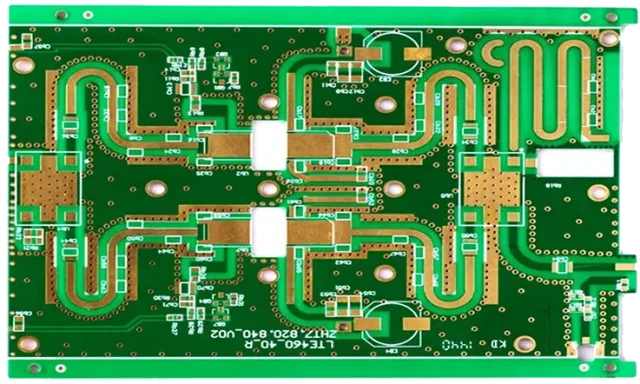

A RO4350B PCB is a high-frequency printed circuit board fabricated using Rogers RO4350B laminate, a hydrocarbon ceramic-filled material specifically designed for RF and microwave applications. RO4350B PCBs provide low dielectric loss, stable dielectric constant (Dk), and excellent thermal performance, making them a popular alternative to PTFE-based RF materials.

Compared with standard FR-4 PCBs, RO4350B PCBs offer better signal integrity, lower insertion loss, and more consistent RF performance, especially in high-frequency designs.

Key Properties of RO4350B PCB Material

Rogers RO4350B material offers several advantages for RF PCB applications:

-

Stable dielectric constant (Dk ≈ 3.48)

Ensures consistent impedance control across frequency ranges. -

Low dissipation factor (Df ≈ 0.0037 @ 10 GHz)

Minimizes signal loss in high-frequency circuits. -

Excellent thermal stability

Suitable for lead-free assembly processes. -

Low coefficient of thermal expansion (CTE)

Improves reliability of plated through holes. -

FR-4–like fabrication process

Allows RO4350B PCBs to be manufactured using standard PCB processes.

These properties make RO4350B PCB ideal for demanding RF designs.

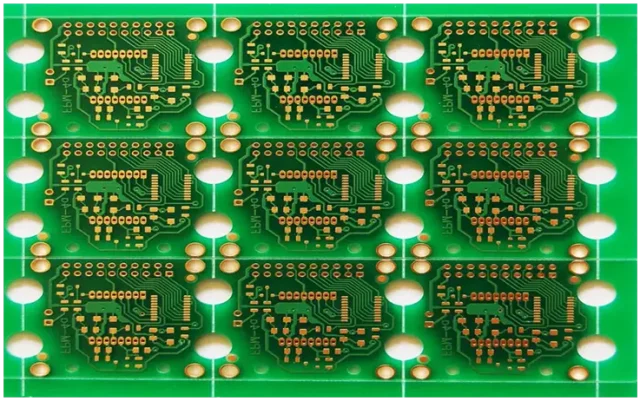

RO4350B PCB Manufacturing Considerations

Manufacturing a RO4350B PCB requires experience with RF materials and impedance control:

-

Precise impedance control

Tight control of trace width, spacing, and dielectric thickness. -

High-precision etching

Ensures RF trace geometry accuracy. -

Surface roughness control

Smooth copper reduces conductor loss. -

Accurate layer registration

Critical for multilayer RO4350B PCBs. -

Impedance and electrical testing

Verifies RF performance before delivery.

Although RO4350B uses FR-4–compatible processes, RF-specific process control is essential.

Advantages of RO4350B PCB

Using a RO4350B PCB provides multiple benefits:

-

Lower RF signal loss compared to FR-4

-

Excellent impedance stability

-

Cost-effective alternative to PTFE materials

-

Compatible with standard PCB fabrication

-

Reliable performance in high-frequency and microwave circuits

These advantages make RO4350B PCB a widely adopted solution in RF applications.

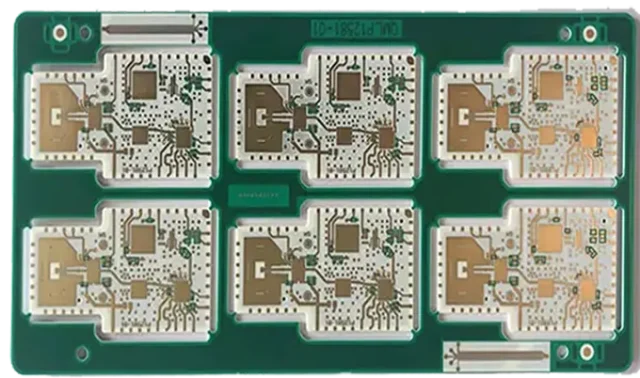

Applications of RO4350B PCB

RO4350B PCBs are commonly used in:

-

RF Test PCB and RF evaluation boards

-

Wireless communication systems (5G, Wi-Fi, LTE)

-

Microwave circuits and amplifiers

-

Automotive radar and ADAS modules

-

Aerospace and defense RF electronics

-

High-speed digital circuits requiring controlled impedance

RO4350B PCB is especially suitable for high-volume RF products requiring stable performance and reasonable cost.

RO4350B PCB vs FR-4 PCB

Compared to FR-4 PCBs, RO4350B PCBs offer:

-

Lower dielectric loss

-

More stable dielectric constant

-

Better RF signal integrity

-

Improved high-frequency performance

For RF and microwave designs, RO4350B PCB provides a significant performance advantage over standard FR-4.

Conclusion

A RO4350B PCB is an excellent choice for high-frequency and RF applications requiring low loss, stable impedance, and reliable thermal performance. With FR-4–like processing compatibility and superior RF characteristics, RO4350B PCBs bridge the gap between standard FR-4 and high-cost PTFE materials.

Choosing an experienced RO4350B PCB manufacturer ensures accurate impedance control, consistent RF performance, and reliable production quality.