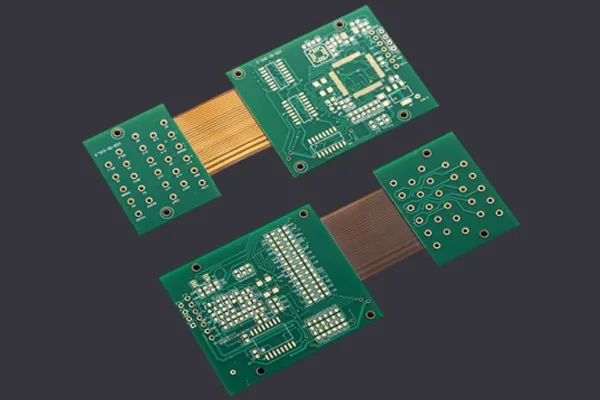

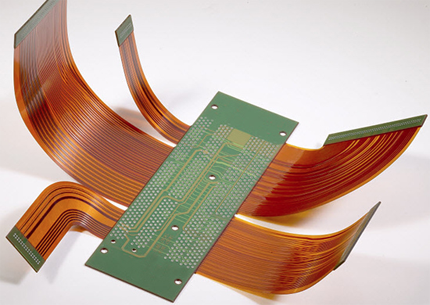

As test systems become more compact and complex, traditional rigid PCBs often struggle to meet mechanical and routing constraints. The Rigid-Flex Test PCB combines rigid board stability with flexible interconnections, enabling reliable testing in space-limited and mechanically dynamic environments.

Rigid-flex technology is increasingly essential for modern test and validation platforms.

What Is a Rigid-Flex Test PCB?

A Rigid-Flex Test PCB integrates rigid sections for component mounting and flexible circuits for interconnection within a single structure. This design eliminates connectors and cables, improving reliability and signal performance in test applications.

Why Rigid-Flex Matters in Test Environments

Test systems demand repeatable performance and mechanical stability. Rigid-flex test PCBs provide:

-

Reduced interconnect failures

-

Improved vibration and shock resistance

-

Compact system layouts

These advantages are critical for long-term test reliability.

Signal Integrity Benefits for High-Speed Testing

High-speed and high-frequency test signals benefit from rigid-flex designs through:

-

Shorter signal paths

-

Fewer discontinuities

-

Controlled impedance routing across rigid and flex sections

This results in cleaner signals and more accurate measurements.

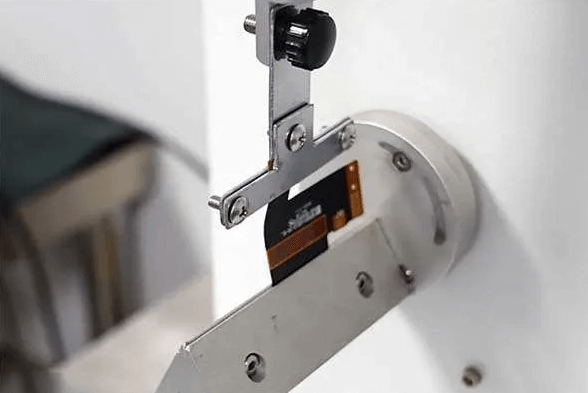

Mechanical Flexibility and Durability

Rigid-flex test PCBs are designed to withstand:

-

Repeated bending during installation

-

Thermal cycling in test environments

-

Mechanical stress from fixtures and sockets

Proper material selection ensures long service life.

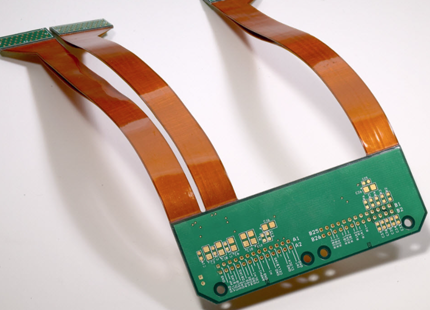

Design Considerations for Rigid-Flex Test PCBs

Key design factors include:

-

Flex material selection and bend radius control

-

Layer stackup transitions between rigid and flex zones

-

Reinforcement and stiffener placement

Careful design ensures both electrical and mechanical performance.

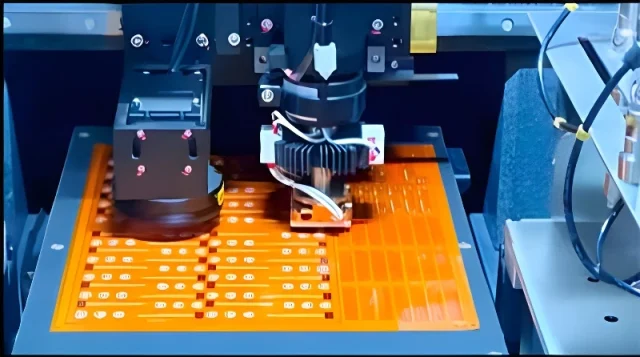

Manufacturing Challenges and Quality Control

Producing rigid-flex test PCBs requires:

-

Precise lamination control

-

Accurate layer alignment

-

Strict impedance and continuity testing

Experienced manufacturing is essential for consistent results.

Typical Applications of Rigid-Flex Test PCBs

Rigid-flex test PCBs are widely used in:

-

ATE systems with space constraints

-

Semiconductor test fixtures

-

High-density probe and socket boards

-

Modular and portable test equipment

These applications benefit from reduced complexity and increased reliability.

Choosing a Rigid-Flex Test PCB Manufacturer

When selecting a rigid-flex test PCB supplier, consider:

-

Proven experience with test and semiconductor boards

-

Advanced rigid-flex fabrication capability

-

Engineering support and DFM feedback

-

Small batch and NPI manufacturing options

The right partner ensures stable and scalable solutions.

Conclusion

The Rigid-Flex Test PCB offers a powerful solution for advanced test environments where space, reliability, and signal integrity are critical. By combining mechanical flexibility with robust electrical performance, rigid-flex test PCBs enable more compact, reliable, and efficient test systems.

Working with an experienced rigid-flex test PCB manufacturer helps ensure long-term performance and smooth transition from engineering validation to production.