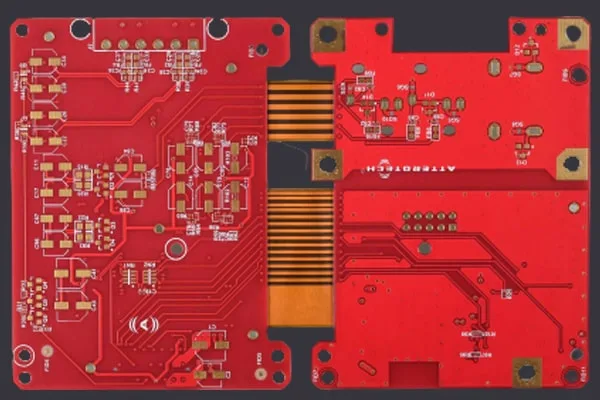

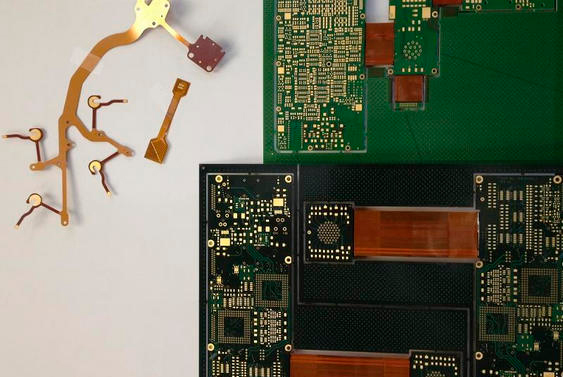

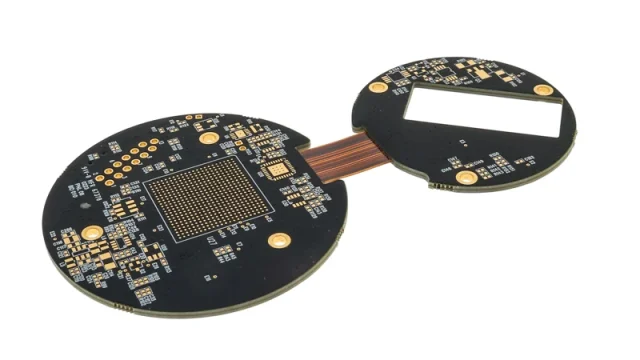

Modern electronic and semiconductor test systems are becoming more compact and mechanically complex. Rigid-flex test PCBs provide an ideal solution by integrating rigid circuit sections with flexible interconnects, enabling reliable electrical performance while meeting demanding space and mechanical requirements in test environments.

What Is a Rigid-Flex Test PCB?

A rigid-flex test PCB is a hybrid circuit board that combines rigid PCB sections with flexible circuits in a single integrated structure. This design eliminates the need for connectors or cables between boards, improving signal integrity and mechanical reliability during testing.

Rigid-flex test PCBs are widely used in advanced test fixtures and ATE systems.

Advantages of Rigid-Flex Test PCBs

Rigid-flex test PCBs offer several key benefits for test applications:

-

Improved Signal Integrity: Shorter interconnects reduce loss and reflections.

-

Mechanical Reliability: Flexible sections absorb vibration and repeated movement.

-

Space Optimization: Enables compact test fixture and system designs.

-

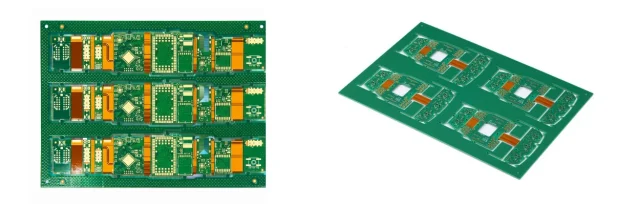

Reduced Assembly Complexity: Fewer connectors and cables simplify assembly.

These advantages lead to more stable and repeatable test results.

High-Speed and Controlled Impedance Design

In high-speed testing, maintaining signal integrity is critical. Rigid-flex test PCBs are engineered with:

-

Controlled impedance routing across rigid and flexible sections

-

Continuous reference planes

-

Carefully designed bend regions

This ensures consistent electrical performance even in compact layouts.

Manufacturing Challenges and Quality Control

Producing high-quality rigid-flex test PCBs requires advanced manufacturing processes, including:

-

Precise alignment between rigid and flexible layers

-

Reliable lamination and coverlay application

-

Strict control of bend radius and copper thickness

Thorough inspection and testing are essential to ensure long-term reliability.

Applications of Rigid-Flex Test PCBs

Rigid-flex test PCBs are commonly used in:

-

ATE interface boards and load boards

-

Semiconductor testing fixtures

-

Compact high-speed test modules

-

Custom test adapters and sockets

These applications benefit from both electrical performance and mechanical flexibility.

Choosing a Rigid-Flex Test PCB Manufacturer

When selecting a Rigid-Flex Test PCB supplier, consider:

-

Experience in rigid-flex PCB design and fabrication

-

Capability for controlled impedance and high-speed testing

-

Support for prototypes and small batch production

-

Comprehensive quality control and testing processes

An experienced manufacturer ensures reliability and consistency in demanding test environments.

Conclusion

Rigid-flex test PCBs provide a powerful combination of electrical performance, mechanical flexibility, and space efficiency for modern test systems. By eliminating connectors and improving signal integrity, rigid-flex test PCB solutions enhance test reliability and system durability.

Partnering with a professional Rigid-Flex Test PCB manufacturer ensures precision, performance, and long-term stability from prototype to production.