Ensuring Long-Term RF Stability Through KKPCB’s Reliability Validation Process

Why Reliability Defines Success in RO4835-Based RF Systems

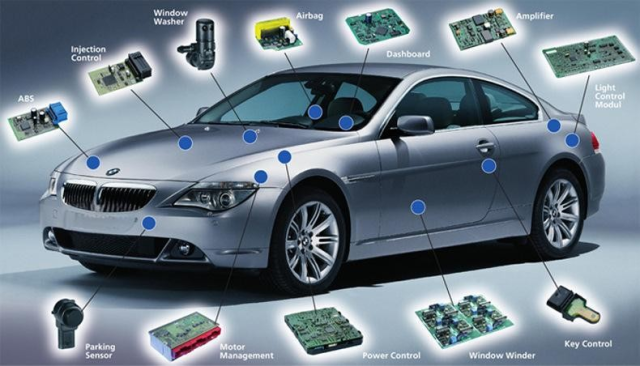

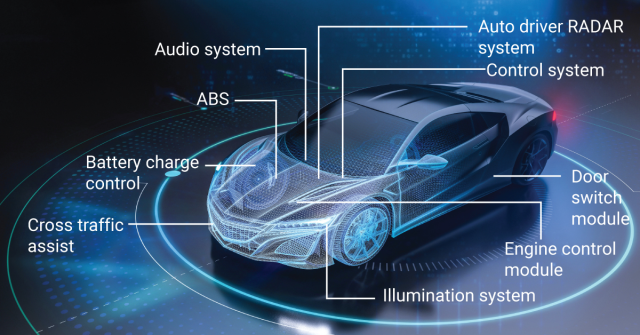

As automotive radar, aerospace communication, and satellite navigation systems expand into 24–77 GHz frequency ranges, PCBs face extreme operational stress. These high-frequency modules must withstand thermal cycling, humidity exposure, and long-term RF power loading, while maintaining tight impedance control and low dielectric drift.

Rogers RO4835 has become a trusted material choice for engineers—offering low loss (Df = 0.0037 @ 10 GHz), stable dielectric constant (Dk = 3.48 ± 0.05), and oxidation-resistant resin chemistry that ensures long-term reliability even in harsh automotive or aerospace environments.

However, material properties alone are not sufficient. True reliability in RO4835 PCB manufacturing depends on comprehensive validation—from RF impedance precision to thermal fatigue endurance—all tested under real-world mass production conditions.

That’s where KKPCB’s RF reliability validation framework bridges the gap between prototype performance and scalable, field-proven manufacturing.

Key Reliability Challenges in RO4835 PCB Production

| Reliability Concern | Root Cause | Impact |

|---|---|---|

| Impedance Drift | Lamination pressure or resin thickness variation | RF mismatch, phase shift, and signal distortion |

| Delamination | CTE mismatch between RO4835 and FR-4 | Layer cracking during thermal cycling |

| Oxidation Degradation | Long-term exposure to high temperature | Dielectric drift and signal loss |

| Moisture Absorption | Humidity in storage or operation | Increased loss tangent, degraded signal quality |

KKPCB mitigates these risks through precision lamination control, in-line impedance verification, and accelerated reliability testing across every production batch.

KKPCB’s Comprehensive RF Reliability Framework

KKPCB integrates RF performance validation with mechanical reliability evaluation to ensure every RO4835 PCB meets automotive-grade and aerospace-level standards.

1. High-Frequency RF Validation

Test Range: DC – 110 GHz

Equipment: Vector Network Analyzer (VNA), Time Domain Reflectometry (TDR)

Measured Parameters:

-

Insertion Loss (S21)

-

Return Loss (S11)

-

Impedance Stability (±5%)

Result Example:

After 500 hours at 150°C, a 24 GHz signal trace maintained < 0.25 dB/inch insertion loss, demonstrating stable dielectric performance under thermal stress.

2. Thermal Cycling & Oxidation Aging

Test Method: IPC-TM-650

Conditions: –40°C ↔ +150°C for 1,000 cycles; Aging at 150°C for 1,000 hours

Results:

-

Impedance variation < ±3%

-

No delamination or cracks under X-ray inspection

Engineering Comparison:

RO4350B showed Df drift (0.0065 → 0.0074) after aging,

while RO4835 remained stable (0.0037 ± 0.0002) — proving its superior oxidation-resistant chemistry.

3. Moisture & Humidity Resistance

Test Profile: 85°C / 85% RH for 1,000 hours

Measured Change:

-

Moisture absorption < 0.1%

-

Dk/Df variation < 0.03

Ensuring stable signal integrity and minimal loss increase under humid conditions—critical for automotive radar modules and aerospace payload boards.

4. Thermal Shock & Mechanical Fatigue

In hybrid stackups combining RO4835 with FR-4, CTE mismatch (≈11 ppm vs. 17 ppm) can introduce stress during rapid temperature swings.

KKPCB’s Process Control:

-

Balanced press layup design

-

Stepwise lamination profile (180°C / 60 min / 200 psi)

-

Controlled cooling gradient → warpage < 0.15 mm / 250 mm

Reliability Result:

After 500 thermal shock cycles (–55°C ↔ +125°C), cross-section inspection showed no delamination and microvia reliability > 99.8%.

Case Study — 77 GHz Automotive Radar Transceiver Module

A Tier-1 automotive radar manufacturer partnered with KKPCB to develop a 6-layer hybrid RO4835 + FR-4 PCB for a 77 GHz radar front-end.

Design Targets:

-

Impedance stability ±5% across RF layers

-

Oxidation resistance @150°C for 1,000 hr

-

Panel warpage < 0.15 mm

| Parameter | Initial | After Reliability Test |

|---|---|---|

| Insertion Loss (S21) | 0.26 dB/inch | 0.27 dB/inch |

| Impedance Variation | ±4.8% | ±3.2% |

| Delamination Rate | 3.1% | < 0.5% |

Outcome: Passed AEC-Q200 qualification, confirming RO4835’s suitability for long-term automotive radar deployment.

Aerospace Qualification — Phase Stability Under Vacuum

For satellite payload and aerospace RF systems, dimensional stability and phase linearity are mission-critical.

-

Outgassing < 0.3% TML (ASTM E595)

-

RF phase shift < 1° @ 30 GHz (–55°C → +125°C)

-

No voids or delamination after 1,000 thermal cycles

These results confirm RO4835 PCB’s reliability under vacuum and high thermal gradient environments—meeting the strict demands of aerospace-grade TDK and RF performance.

KKPCB’s Reliability Assurance Framework

To ensure traceability and batch consistency, KKPCB implements a five-layer QA system:

-

Material Incoming Inspection (Dk/Df measurement per lot)

-

Lamination Profile Simulation for CTE balancing

-

In-line Impedance Verification (VNA up to 110 GHz)

-

Accelerated Aging Tests (thermal & humidity cycles)

-

Failure Mode Analysis (voids, delamination, dielectric drift)

This framework ensures data-backed reliability reports for OEMs in automotive radar, aerospace communication, and satellite control modules.

Conclusion — Proven RF Reliability with RO4835 PCB

RO4835 PCB technology combines electrical accuracy, thermal stability, and oxidation resistance, making it the preferred choice for 5G, radar, and aerospace modules.

Through KKPCB’s comprehensive RF testing and reliability validation, each board is verified for impedance stability, thermal endurance, and lifecycle consistency—ensuring that every production lot performs to specification.

Partner with KKPCB for High-Reliability RO4835 PCBs

KKPCB’s RF engineering team offers:

-

Custom reliability and lifecycle test programs

-

Impedance & insertion loss validation

-

Hybrid stackup optimization for TDK-controlled consistency

-

Automotive & aerospace qualification documentation

Contact KKPCB Engineering Support to discuss your RO4835 reliability project or request a technical DFM and reliability review.