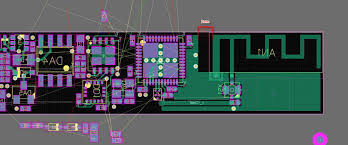

RF PCB Design for 5G Devices: High-Frequency Architecture, Antenna Integration & Engineering Best Practices

Designing RF PCBs for 5G hardware is far more than simple high-speed layout—it requires a deep command of electromagnetic behavior, antenna engineering, high-frequency signal routing, impedance control, and noise isolation.

In next-generation wireless systems, the antenna is no longer a passive component—it directly defines link budget, range, spectral efficiency, and overall device performance.

This guide provides a comprehensive, engineer-oriented breakdown of 5G RF PCB design principles, antenna integration strategies, and practical layout considerations to help you build reliable, production-ready radio systems.

1. Key Principles of 5G RF PCB Engineering

High-frequency PCB success depends on four essential design pillars:

Antenna integrity & placement

Antenna performance degrades dramatically if placed near metal structures, noisy components, or inconsistent ground references.

Controlled impedance signal paths

5G frequencies (sub-6 GHz to mmWave) require extremely tight impedance tolerance to avoid reflections and insertion loss.

Low-noise RF layout

5G radios are extremely sensitive to power noise, switching harmonics, and digital coupling.

Material selection

Ceramic-filled PTFE, hydrocarbon laminates, and low-loss dielectrics are preferred over FR-4 for stable signal propagation.

2. Selecting Antennas for 5G & IoT PCB Designs

Modern PCB-integrated antennas typically operate from 400 MHz to 5.5 GHz, with mmWave extensions for advanced 5G NR bands.

Choosing the correct antenna requires balancing:

Essential Selection Criteria

-

Frequency band

-

Antenna size

-

Form factor

-

Radiation pattern

-

Gain requirements

-

Polarization

-

Ground plane constraints

-

Cost

5G Trend: High-Gain Miniature Antennas

5G and IoT devices increasingly rely on compact, multi-band antennas with higher gain to support dense connected environments and high throughput.

This drives heavy adoption of MIMO arrays—with 8×8 configurations becoming standard in many LTE-Advanced and 5G platforms.

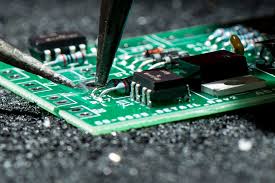

3. PCB Antennas: Types & Design Considerations

PCB antennas are cost-efficient and easy to manufacture, though they require careful layout discipline.

3.1 PCB Antenna Categories

-

Inverted-F antenna (IFA)

-

Meandered inverted-F antenna (MIFA)

-

Inverted-L

-

Folded monopole

-

Meandered trace

-

Circular trace

The ground plane is the dominant factor influencing bandwidth, radiation efficiency, and field uniformity.

3.2 Dipole & Monopole Antennas

Dipole Antennas

Two linear conductive elements—less common in compact 5G devices.

Quarter-Wave Monopole Antennas

-

Most widely used in PCB designs

-

Fed single-ended

-

Ground plane acts as the mirror element

-

Suitable for both sub-6 GHz and mmWave bands (24–100 GHz)

3.3 Inverted-F Antennas (IFA)

A robust, compact antenna structure ideal for BLE, Wi-Fi, and mid-band 5G applications.

Advantages

-

Small size

-

Efficient radiation

-

Easy impedance matching

-

Direct PCB integration with no external components

Feed Line Optimization

Antenna feed width depends on PCB thickness (FR-4, Er 4.3):

Thickness (mil) |

Feed Width W (mil) |

|---|---|

| 60 | 65 |

| 50 | 59 |

| 40 | 52 |

| 30 | 44 |

| 20 | 33 |

3.4 Meandered-IFA (MIFA)

Designed where PCB area is extremely limited—ideal for wearables, mice, presenters, and compact BLE modules.

Antenna length depends on PCB thickness:

PCB Thickness (mil) |

MIFA Length |

|---|---|

| 16 | L_tip = 353 mil |

| 31 | L_tip = 165 mil |

| 47 | L_tip = 125 mil |

| 62 | L_leg = 115 mil |

8 Professional Tips for IFA / MIFA Optimization

-

Use a 50-ohm microstrip feed with optional tuning components.

-

Set radiator length to λ/4 of the target frequency.

-

Connect radiator to ground using a shorting pin/strip.

-

Use ground vias for a low-inductance return path.

-

Never place ground under the antenna area.

-

Cover the antenna with solder mask for durability.

-

Keep copper pours out of antenna zones.

-

Ensure ground plane height ≥ λ/4 to avoid bandwidth loss.

IFA is generally superior to MIFA when space allows due to higher radiation efficiency.

4. Wire, Chip, Patch & External Antennas

4.1 Wire Antennas

-

Quarter-wave vertical structures

-

Excellent 3D radiation

-

Not ideal for compact 5G devices due to height

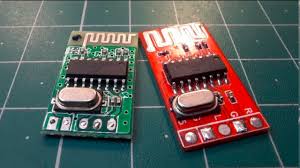

4.2 Chip Antennas

-

Very compact, suitable for IoT

-

Require large ground plane

-

Cost: $0.10–$0.50

-

Require external matching networks

4.3 Patch Antennas

Perfect for GPS, 5G NR, IoT, and small-cell systems.

Support:

-

Linear polarization

-

RHCP / LHCP

-

Dual-polarized configurations

4.4 Whip & Paddle Antennas

-

External, connector-based

-

Used for LoRa, LPWAN, ISM

-

Great modularity

5. RF PCB Antenna Comparison (2.44 GHz)

Property |

IFA |

MIFA |

Chip |

Wire |

|---|---|---|---|---|

| Size (mil) | 157.5×807 | 284×437 | 126×63 | 250×1200 |

| Cost | Minimal | Minimal | $0.10–0.50 | ~$0.10 |

| Bandwidth (MHz, S11 ≤ –10 dB) | 220 | 230 | 200 | 200 |

| Gain (dBi) | 1.1 | 1.6 | 0.5 | 2.0 |

| Best Use | Height-limit designs | Ultra-compact | Tiny IoT nodes | Tall enclosures |

6. RF PCB Layout Guidelines for 5G Devices

1. Place MIMO antennas on PCB corners

Provides isolation, free-space exposure, and reduced mutual coupling.

2. Respect antenna keep-out regions

No metal, vias, components, screws, or traces.

3. Avoid placing antennas near:

-

Batteries

-

LCD modules

-

High-speed processors

-

Switching regulators

-

HDMI or metal shields

4. Use the 8-degree clearance rule

No components should enter the 8° projection boundary around the antenna region.

5. Maintain antenna isolation

-

≥ 10 dB separation below 1 GHz

-

≥ 20 dB for frequencies up to 20 GHz

Use rotation (90°/180°) to maximize orthogonality.

6. Align antenna with final product orientation

Critical for predictable radiation patterns.

7. Avoid metal covers

Metal enclosures detune antennas unless a dedicated RF window is engineered.

8. Keep antennas away from high-εr plastics

Prevents resonant frequency drift and pattern distortion.