Understanding PTFE PCB: A Comprehensive Technical Overview

Printed circuit boards (PCBs) form the backbone of modern electronic systems. While FR4 remains the industry standard for general-purpose PCB manufacturing, PTFE PCBs occupy a special place in high-performance, high-frequency, and harsh-environment applications. This guide provides an in-depth exploration of PTFE PCB technology—its material properties, technical specifications, differences compared to FR4, application scenarios, and how to select the right substrate for your design.

What Is a PTFE PCB?

A PTFE PCB is a printed circuit board built using substrates based on PTFE (Polytetrafluoroethylene)—a high-performance fluoropolymer more commonly recognized under the brand name Teflon. Unlike FR4, PTFE substrates offer exceptional electrical, thermal, and chemical stability, making them ideal for RF, microwave, radar, aerospace, defense, and high-speed digital circuits.

Key advantages include:

-

Ultra-low dielectric loss

-

Highly stable dielectric constant

-

Extreme temperature tolerance (cryogenic to >250°C)

-

Outstanding chemical inertness

-

Excellent moisture and weather resistance

Because of these properties, PTFE PCBs deliver reliability and signal integrity where standard FR4 materials cannot.

Key Properties of PTFE PCBs

Below is a breakdown of the fundamental properties that distinguish PTFE PCBs from conventional laminates:

1. Chemical Resistance

PTFE is inert to almost all industrial acids, bases, solvents, oils, and corrosive chemicals. This allows PTFE-based PCBs to perform reliably in harsh chemical environments.

2. Extreme Temperature Tolerance

-

Performs reliably from −196°C to +260°C

-

No brittleness at cryogenic temperatures

-

No degradation at high continuous operating temperatures

This makes PTFE suitable for aerospace, military, and industrial power systems.

3. Weather & UV Resistance

PTFE maintains stability under:

-

UV exposure

-

High humidity

-

Outdoor environmental cycles

-

Abrasive or contaminated atmospheres

4. Ultra-Low Dielectric Loss

The non-polar molecular structure of PTFE results in very small dielectric loss tangent, enabling:

-

High-frequency signal integrity

-

Low-loss RF transmission lines

-

Stable impedance for microwave systems

5. Moisture Resistance

PTFE absorbs almost no moisture (0.03–0.1%), preventing:

-

Dielectric drift

-

Electrical leakage

-

Delamination

6. Excellent Electrical Performance

-

Dielectric constant (Dk): ~2.0–2.6

-

Dielectric strength: 300–500 V/mil

-

Volume resistivity: 10⁵–10⁷ MΩ·cm

These properties make PTFE one of the most stable materials for controlled-impedance circuit design.

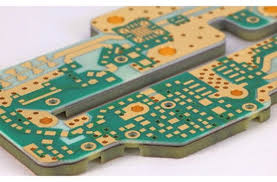

Typical Specifications of Common PTFE PCB Materials

PCB Material |

Dk (Dielectric Constant) |

Thermal Coefficient of Dk |

Volume Resistivity |

Moisture Absorption |

Thermal Conductivity |

Density |

Copper Peel Strength |

|---|---|---|---|---|---|---|---|

| RO3003 | 3.00±0.04 | -3 ppm/°C | 10⁷ MΩ·cm | 0.04% | 0.50 W/m·K | 2.1 g/cm³ | 12.7 lb/in |

| RO3035 | 3.00±0.05 | -45 ppm/°C | 10⁷ MΩ·cm | 0.04% | 0.50 W/m·K | 2.1 g/cm³ | 10.2 lb/in |

| RO3006 | 6.15±0.15 | -262 ppm/°C | 10⁵ MΩ·cm | 0.02% | 0.79 W/m·K | 2.6 g/cm³ | 7.1 lb/in |

| RO3010 | 10.2±0.30 | -395 ppm/°C | 10⁵ MΩ·cm | 0.05% | 0.95 W/m·K | 2.8 g/cm³ | 9.4 lb/in |

PTFE vs FR4 PCB — Key Differences & Selection Guide

Although FR4 remains the dominant PCB material, PTFE provides unmatched performance in extreme environments and RF applications.

Comparison Table

Property |

FR4 |

PTFE |

|---|---|---|

| Maximum Temperature | ~110°C | −192°C to >260°C |

| Dielectric Constant | 3.8–4.8 | 2.1–2.6 |

| Dielectric Strength | 150–200 V/mil | 300–500 V/mil |

| Water Absorption | ~0.1% | 0.03–0.1% |

| Chemical Resistance | Moderate | Excellent (inert to almost all chemicals) |

| Thermal Conductivity | 0.3–0.6 W/m·K | 0.44–0.95 W/m·K |

| Flexibility | Rigid | Rigid or Flexible |

| Cost | Low | 5–10× higher |

How to Choose?

Choose PTFE when:

Choose PTFE when:

-

High-frequency / RF signals require low loss

-

Wide temperature ranges are involved

-

Chemical resistance is critical

-

Signal integrity and impedance tolerance are strict

-

Mission-critical reliability is required

Choose FR4 when:

-

The application is cost-sensitive

-

Operating temperature is moderate

-

Signal frequencies are low or moderate

-

Mechanical demands are typical

Applications of PTFE PCBs

PTFE PCBs are utilized where traditional materials fail:

1. Aerospace & Defense

-

Radar systems

-

Avionics signal controls

-

Satellite communication modules

-

High-temperature mission systems

2. Telecommunications & RF

-

5G base stations

-

RF amplifiers

-

Microwave antennas

-

Millimeter-wave systems

3. Industrial Electronics

-

Harsh-chemical manufacturing

-

High-temperature power controllers

-

Precision measurement instruments

4. Medical Electronics

-

Imaging equipment (MRI, CT)

-

Patient monitoring systems

-

Biocompatible and sterilizable devices

Choosing the Right PTFE PCB Manufacturer

Due to the difficulty of processing PTFE materials (softness, dimensional stability issues, high drilling wear), selecting a capable PCB manufacturer is critical.

A qualified PTFE PCB supplier must offer:

-

Specialized lamination and drilling equipment

-

Experience with Rogers, Taconic, Arlon, and other fluoropolymer laminates

-

Controlled impedance fabrication capability

-

RF-optimized stack-up engineering