PCB Turnkey Services: A Complete One-Stop Solution for PCB Manufacturing and Assembly

In today’s fast-paced electronics industry, reducing supply chain complexity and accelerating time to market are critical for success. PCB Turnkey services provide a complete, one-stop solution that covers every stage of electronics production—from PCB fabrication and component sourcing to assembly, testing, and final delivery.

This blog explains what PCB Turnkey means, how it works, and why it has become the preferred manufacturing model for startups and established electronics companies alike.

What Is PCB Turnkey?

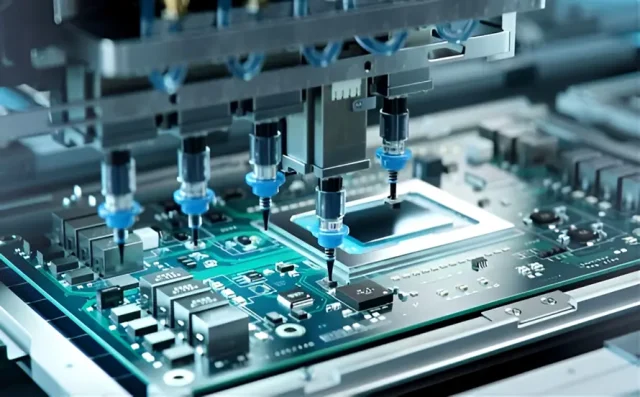

PCB Turnkey refers to a manufacturing service where a single supplier takes full responsibility for the entire PCB and PCBA process. Customers only need to provide design files and requirements, while the manufacturer manages all production steps.

A typical PCB Turnkey solution includes:

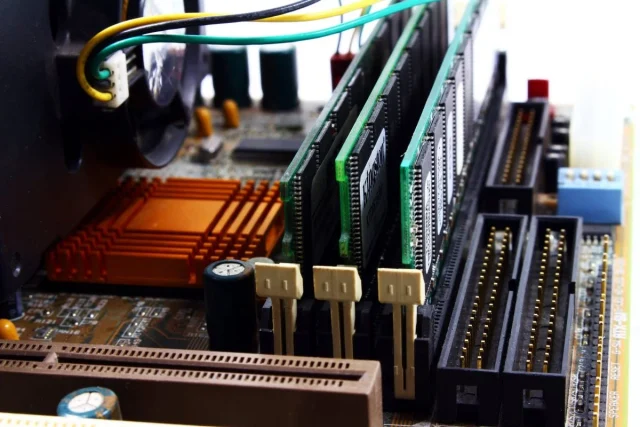

- PCB fabrication

- Electronic component sourcing and procurement

- SMT and THT PCB assembly

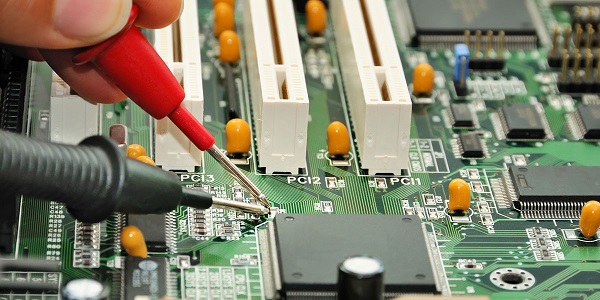

- Inspection and testing (AOI, X-ray, functional testing)

- Packaging and logistics

By choosing a PCB Turnkey partner, customers benefit from simplified project management and consistent quality control.

How PCB Turnkey Services Work

The PCB Turnkey process begins with design data review and BOM evaluation. After confirming specifications, the manufacturer sources components, fabricates the PCB, and completes assembly and testing under one coordinated workflow.

Because all steps are managed by a single supplier, communication gaps and production delays are significantly reduced. This integrated approach ensures faster lead times and higher production efficiency.

Types of PCB Turnkey Services

PCB Turnkey solutions can be customized based on customer needs:

- Full PCB Turnkey: The manufacturer supplies the PCB, all components, assembly, and testing.

- Partial PCB Turnkey: The customer provides some components, while the manufacturer sources the rest.

- Consigned PCB Assembly: The customer supplies all components, and the manufacturer focuses on assembly only.

This flexibility allows customers to balance cost control and supply chain preferences.

Key Advantages of PCB Turnkey Manufacturing

Choosing PCB Turnkey manufacturing offers several important benefits:

- Reduced Supply Chain Complexity: One supplier manages the entire process.

- Shorter Lead Times: Integrated production minimizes delays.

- Cost Efficiency: Optimized sourcing and process coordination lower overall costs.

- Improved Quality Control: Centralized responsibility ensures consistent standards.

- Single Point of Accountability: Easier communication and problem resolution.

These advantages make PCB Turnkey an ideal solution for both prototyping and mass production.

Applications of PCB Turnkey Services

PCB Turnkey services are widely used across multiple industries, including:

- Consumer electronics

- Automotive electronics

- Medical devices

- Industrial control systems

- High-speed, RF, and high-frequency PCB projects

Whether for low-volume prototypes or high-volume production, PCB Turnkey services provide scalability and reliability.

Conclusion

PCB Turnkey services offer a streamlined, efficient, and reliable manufacturing model for modern electronics production. By integrating PCB fabrication, component sourcing, assembly, and testing under one roof, PCB Turnkey solutions help companies reduce risk, control costs, and accelerate product development.

Partnering with an experienced PCB Turnkey manufacturer ensures consistent quality, faster delivery, and long-term production success.