When working with high-frequency and microwave circuits, knowing how to order microwave PCB correctly is essential for ensuring stable signal transmission and system reliability. Microwave PCBs operate at GHz and mmWave frequencies, where even small manufacturing variations can significantly affect performance.

This guide outlines the key considerations when ordering microwave PCBs and how to select a reliable manufacturing partner.

What Is a Microwave PCB?

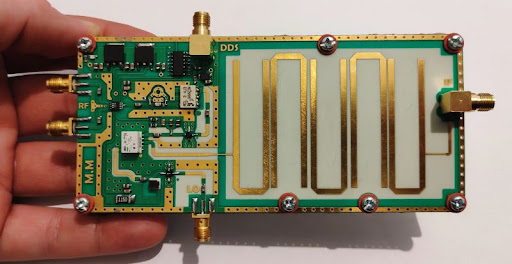

A microwave PCB is designed for circuits operating at microwave frequencies, typically above 1 GHz. These PCBs are widely used in RF front-end modules, radar systems, satellite communication, and 5G infrastructure.

Microwave PCBs require specialized materials, tight impedance control, and precise manufacturing processes.

Key Factors to Consider When You Order Microwave PCB

1. Microwave PCB Material Selection

Material choice is critical when you order microwave PCB. Common microwave materials include:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

Taconic RF materials

-

PTFE-based laminates

-

Hybrid stackups combining microwave materials with FR-4

Low dielectric constant (Dk) and low dissipation factor (Df) help minimize signal loss at microwave frequencies.

2. Impedance Control and Signal Integrity

Accurate impedance control ensures proper signal matching:

-

Controlled trace geometry and stack-up

-

Tight tolerance control (±5% or better)

-

TDR testing for impedance verification

Reliable impedance control improves microwave circuit performance and repeatability.

3. Manufacturing Precision and Quality

High-quality microwave PCB manufacturing includes:

-

Precision etching and lamination

-

Fine line width and spacing control

-

Controlled copper thickness and surface finish

-

Strict quality inspection and testing

These factors directly affect insertion loss and signal stability.

How to Choose the Right Supplier to Order Microwave PCB

When selecting a supplier, consider:

-

Experience in microwave and RF PCB manufacturing

-

Material availability and processing expertise

-

RF testing and quality assurance capability

-

Transparent pricing and lead time

-

Engineering and DFM support

An experienced supplier reduces risk and ensures consistent results.

From Microwave PCB Order to Production

After you order microwave PCB, a professional manufacturer should support:

-

Prototype and small batch production

-

Design review and optimization

-

Smooth transition to mass production

Strong technical support ensures efficient product development.

Conclusion

To successfully order microwave PCB, it is essential to focus on material selection, impedance control, and manufacturing quality. Choosing an experienced microwave PCB manufacturer ensures reliable performance, stable delivery, and professional technical support.

By partnering with the right supplier, you can confidently develop and scale high-performance microwave and RF products.