IoT-enabled agricultural UAVs operate in a uniquely demanding environment: wide temperature swings, continuous vibration, variable humidity, and rapidly changing RF propagation conditions over open farmland. These drones must maintain long-range wireless links, collect high-resolution crop data, and execute precision-controlled spraying while keeping power consumption and mass as low as possible.

To meet these requirements, modern agricultural drones depend on high-frequency PCB architectures, optimized RF routing, low-loss materials, and thermally stable multilayer constructions. The integrity of these PCBs directly determines UAV connectivity, sensor accuracy, and reliability in large-scale smart-farming ecosystems.

Key Engineering Drivers in Agricultural UAV Electronics

High-performance agricultural UAVs require PCBs that can sustain:

• Low-loss RF transmission for farm-to-base communication over multi-kilometer ranges

• Stable impedance control to prevent RF drift in Wi-Fi 6/6E, Sub-GHz ISM, and 5G-NR IoT bands

• Robust thermal endurance when drones operate under direct sunlight or carry high-power actuators

• High-frequency routing precision for GNSS modules, multispectral imaging units, and radar altimeters

• EMI resilience in environments where multiple IoT devices function simultaneously

• Lightweight, compact, high-density PCB stackups to reduce flight load and maximize battery runtime

These demands make advanced HF PCB materials essential for agricultural UAV reliability.

Material Engineering — Low-Loss Laminates Enable IoT Reliability

Agricultural drones typically integrate RF communication modules operating across:

• 433 / 868 / 915 MHz ISM IoT bands

• 2.4 / 5.8 GHz WLAN

• 10–24 GHz high-resolution sensing (depending on payload)

To maintain signal integrity across these bands, low-loss PCB substrates such as RO4350B, RO4835, or comparable high-frequency laminates are used. Their engineering advantages include:

• Low Df (<0.004) to suppress insertion loss during long-range telemetry

• Stable Dk tolerances ensuring predictable impedance under temperature shifts

• Enhanced thermal conductivity that prevents hotspot-induced drift around power controllers

• Low moisture absorption, critical for open-field agricultural spraying environments

The combination of dielectric stability and thermal robustness makes HF laminates ideal for UAV IoT applications.

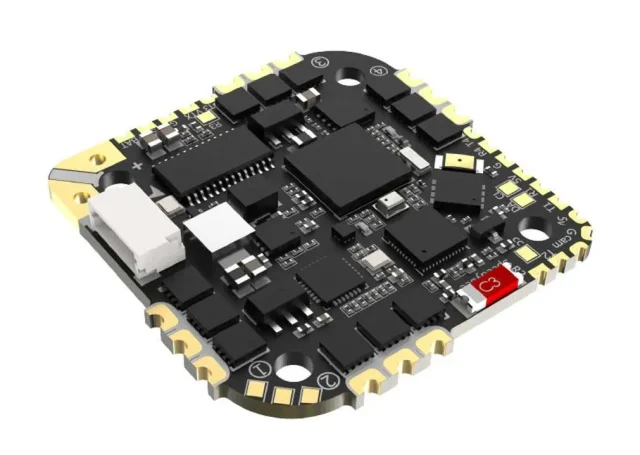

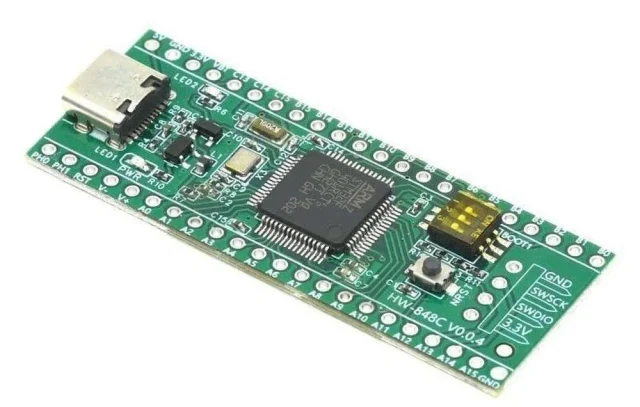

UAV PCB Architecture — High-Frequency Routing for Agricultural IoT Modules

1. Long-Range Communication Link Stability

Agricultural drones rely on telemetry modules, LTE/5G IoT modems, LoRa gateways, or proprietary RF units. Impedance-controlled microstrip and stripline routing helps maintain:

• Multi-kilometer communication range

• Reduced phase noise during long-distance flight

• Higher SNR for video and sensor streaming

Tight impedance windows (±5% or better) minimize reflections and ensure predictable RF behavior.

2. Multispectral & Environmental Sensing Accuracy

UAVs often carry:

• NDVI / multispectral cameras

• Crop-stress imaging sensors

• Soil-moisture or canopy-temperature modules

High-frequency PCB routing suppresses signal distortion and supports the broad sensor bandwidths needed for precise farm mapping.

3. Precision Spraying Control Electronics

Sprayer UAVs require PCBs that can withstand:

• High-voltage actuation

• PWM frequency switching

• Motor and pump EMI

Segmented ground planes and optimized return paths reduce mode conversion and enhance actuator stability.

4. Vibration & Thermal Reliability in Open Fields

Agricultural UAV PCBs must handle:

• Direct sunlight heating

• Continuous mechanical vibration

• Moisture exposure from spraying operations

Multilayer HF PCB stackups with reinforced vias and resin-filled microvias improve structural reliability.

KKPCB Engineering Practices for Agricultural UAV Platforms

KKPCB integrates multiple engineering strategies to enhance UAV reliability:

• Tight dielectric thickness control (±3–5 µm) to protect high-frequency impedance

• Smooth copper (Ra < 1.0 µm) for lower insertion loss in long RF feedlines

• Hybrid stackups combining HF laminates with lightweight FR-4 for cost/weight balance

• Thermal via grids under high-power IoT modules

• Shielded RF zones for GNSS, telemetry, and video transmission

• Comprehensive TDR + HFSS modeling to ensure RF linearity across all flight conditions

These practices produce PCBs engineered for long-term field deployment in demanding agricultural cycles.

Environmental & Lifecycle Considerations for IoT Agriculture UAVs

Agricultural UAVs face harsher environments than most IoT devices. KKPCB validates PCBs through:

• Thermal cycling: –40°C to +125°C simulating early-morning to midday temperature swings

• Humidity endurance: critical for pesticide spraying operations

• Vibration/shock testing: simulating rotor-induced oscillation

• RF reliability tests: long-term insertion loss and phase drift evaluations

• Salt-fog and UV exposure testing: for open-field deployments

High-frequency PCB stability under these conditions is essential for consistent crop monitoring and spraying accuracy.

Conclusion — HF PCB Engineering Enables Scalable Smart Farming

Advanced high-frequency PCB architectures are foundational to modern IoT agricultural UAVs. By implementing low-loss laminates, thermally stable stackups, EMI-resistant routing, and tightly controlled impedance paths, KKPCB delivers PCB solutions that:

• Improve UAV long-range communication

• Enhance multispectral crop-data fidelity

• Stabilize precision spraying systems

• Enable high-density sensor integration

• Ensure reliable operation across harsh agricultural environments

These technologies form the backbone of scalable, data-driven smart farming ecosystems.