As microwave and mmWave semiconductor technologies continue to evolve, accurate testing at GHz-level frequencies is essential. A Microwave IC Test PCB serves as a critical interface between microwave integrated circuits and automated test equipment (ATE), enabling precise signal transmission, impedance control, and reliable measurement results.

These specialized test PCBs are widely used in RF front-end modules, radar ICs, satellite communications, and high-speed wireless systems.

What Is a Microwave IC Test PCB?

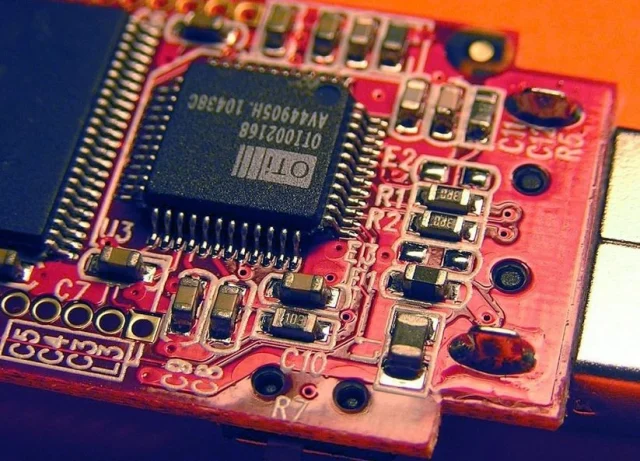

A Microwave IC Test PCB is a high-frequency printed circuit board designed specifically for testing microwave integrated circuits. Unlike standard IC test boards, microwave IC test PCBs must support extremely high signal frequencies, low insertion loss, and minimal signal reflection.

They are commonly used as load boards, probe card interfaces, or custom test fixtures in microwave and mmWave ATE environments.

Key Performance Requirements

Microwave Signal Integrity

Microwave IC test PCBs must maintain stable signal transmission across GHz and mmWave frequency bands, ensuring accurate test data and repeatable results.

Controlled Impedance

Precise impedance control is mandatory to minimize reflections and ensure accurate S-parameter measurements during microwave IC testing.

Low Loss Characteristics

Low dielectric loss materials are required to reduce attenuation and phase distortion at high frequencies.

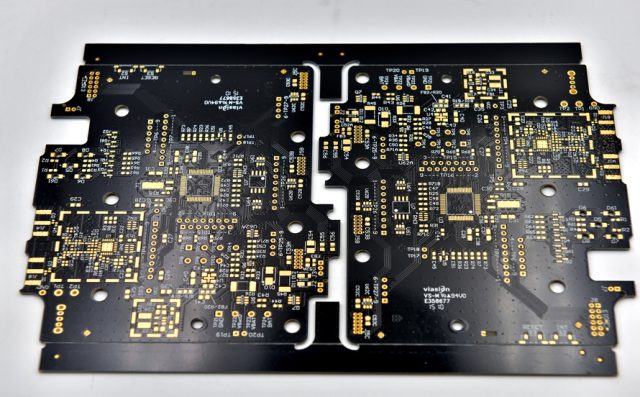

High Pin Count Support

Many microwave ICs feature dense I/O configurations, requiring fine-line routing and multilayer PCB designs.

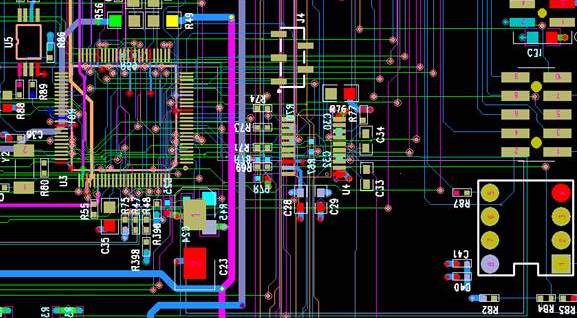

Design Considerations for Microwave IC Test PCBs

Effective microwave IC test PCB design involves:

-

Optimized multilayer stack-up with dedicated RF signal and ground layers

-

Controlled impedance transmission line design

-

Short, direct signal paths to reduce parasitic effects

-

Proper isolation to minimize crosstalk and EMI

-

Precise connector and probe interface placement

Close collaboration between PCB engineers and test engineers is essential for successful microwave testing.

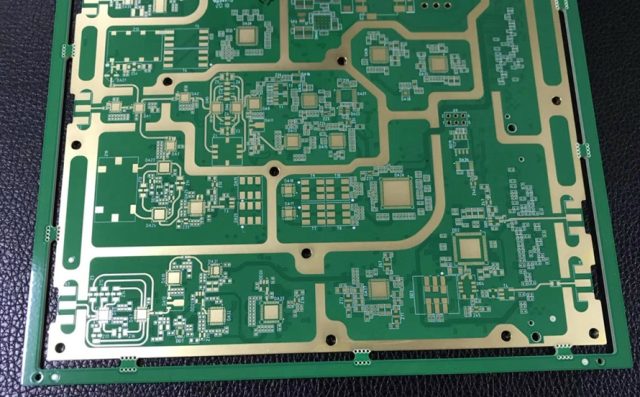

Materials Used in Microwave IC Test PCBs

To achieve optimal performance, microwave IC test PCBs typically use:

-

Rogers RO4350B, RO4003C, or RO5880 laminates

-

Taconic RF-35 or TLY series materials

-

Hybrid stack-ups combining RF laminates and high-Tg FR-4

These materials provide stable dielectric properties and low dissipation factors suitable for microwave applications.

Manufacturing Capabilities

Manufacturing microwave IC test PCBs requires advanced processes, including:

-

Fine line and spacing fabrication

-

Multilayer and HDI PCB technology

-

Blind and buried vias for dense layouts

-

Impedance testing and verification

-

Strict control of material thickness and tolerance

Precision manufacturing ensures consistency across prototype and production builds.

Assembly for Microwave IC Test PCBs

Assembly services may include:

-

High pin count socket and connector installation

-

Fine-pitch SMT assembly

-

Mixed SMT and through-hole assembly

-

X-ray inspection for hidden solder joints

Proper assembly ensures mechanical reliability and electrical performance during repeated test cycles.

Applications of Microwave IC Test PCBs

Microwave IC test PCBs are widely used in:

-

Microwave and mmWave IC characterization

-

RF transceiver and front-end module testing

-

Automotive radar and satellite IC testing

-

Wireless communication IC validation

-

High-speed mixed-signal semiconductor testing

These applications demand precise impedance control and low-loss signal transmission.

Prototype and Small Batch Microwave IC Test PCBs

Prototype and small batch microwave IC test PCBs are critical during early development and validation stages. Fast turnaround and engineering support allow rapid iteration of layouts and materials, helping optimize test accuracy before mass production.

Why Choose a Specialized Microwave IC Test PCB Manufacturer?

A professional microwave IC test PCB supplier offers:

-

Expertise in microwave and mmWave PCB technology

-

Proven experience with controlled impedance testing

-

Support for high pin count and multilayer designs

-

Flexible production volumes from prototype to mass production

This ensures reliable, repeatable, and high-accuracy microwave IC testing.

Conclusion

Microwave IC Test PCB manufacturing plays a vital role in high-frequency semiconductor testing. With low-loss materials, precise impedance control, and advanced fabrication techniques, these PCBs enable accurate measurement, stable performance, and efficient validation of microwave ICs.

Choosing an experienced microwave IC test PCB manufacturer ensures your testing solutions meet the highest performance and reliability standards.