The Evolution of Medical PCBs

Printed circuit boards (PCBs) have become the backbone of modern electro-medical technology. From pacemakers and defibrillators to MRI systems and wearable glucose monitors, the demand for compact, high-performance, and highly reliable electronic assemblies continues to rise. At KKPCB, we understand that medical electronics are not just products—they are lifelines. Every circuit must operate with absolute stability and safety for both patients and healthcare professionals.

Advanced Technologies for Medical PCBs

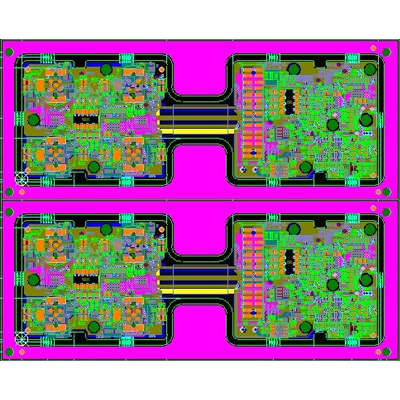

To meet the miniaturization trend in medical electronics, PCB design has entered a new era of precision. High-Density Interconnect (HDI) technology enables smaller, more powerful boards with complex functionality and reduced routing space. KKPCB’s HDI solutions achieve superior trace density and interconnection accuracy, minimizing design error margins and improving thermal management.

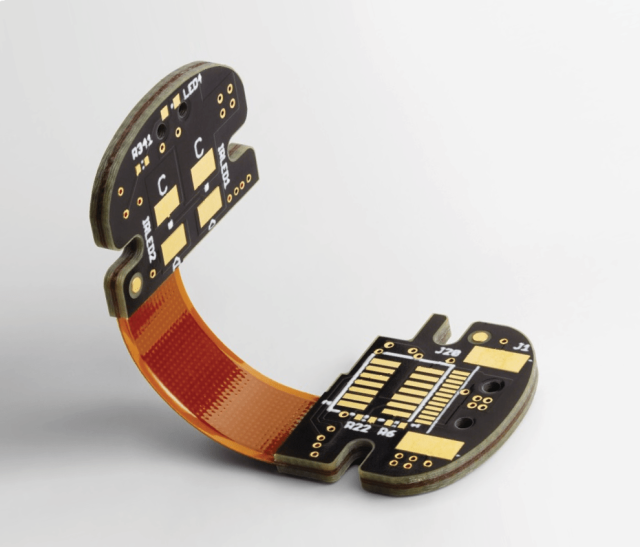

Flex and rigid-flex PCBs are another key technology we excel in. These solutions allow medical devices to adopt unique form factors—lightweight, space-efficient, and ergonomic—while maintaining robust mechanical and electrical performance. KKPCB’s flexible PCB manufacturing enables seamless integration in wearable and implantable devices, supporting the new generation of medical innovation.

Materials and Manufacturing Excellence

Material selection in medical PCB manufacturing is critical. KKPCB utilizes certified RoHS-compliant materials, in1cluding FR-4, polyimide, PTFE, and ceramic laminates, ensuring exceptional dielectric performance, low signal loss, and high thermal stability. Our via-in-pad and laser-drilled microvia processes ensure compact interconnections and enhance overall electrical reliability. With precision equipment such as LDI (Laser Direct Imaging) and mSAP (Modified Semi-Additive Process), KKPCB meets the most stringent standards for trace width, spacing, and layer alignment.

Design for Reliability and Longevity

Every medical PCB we produce is designed for long-term stability and maintainability. By collaborating closely with component suppliers, KKPCB mitigates risks of obsolescence and ensures design continuity throughout the product lifecycle. Our engineers employ 3D modeling and simulation tools, including Digital Twin technology, to predict circuit behavior under various operating conditions, significantly reducing development time and validation costs.

Testing and Verification

KKPCB’s design philosophy integrates testability from the earliest stages. Our boards include optimized test points for debugging, signal integrity analysis, and in-field diagnostics. Thermal simulations and reliability assessments are performed before production, ensuring that each medical PCB meets international safety standards and maintains consistent performance in real-world environments.

KKPCB — Your Trusted Partner in Medical Innovation

With years of expertise in precision PCB manufacturing, KKPCB empowers medical device innovators with dependable circuit solutions. From concept to mass production, we uphold strict quality control, traceability, and compliance with global medical standards. KKPCB’s mission is simple: enabling the future of healthcare technology—safely, reliably, and intelligently.