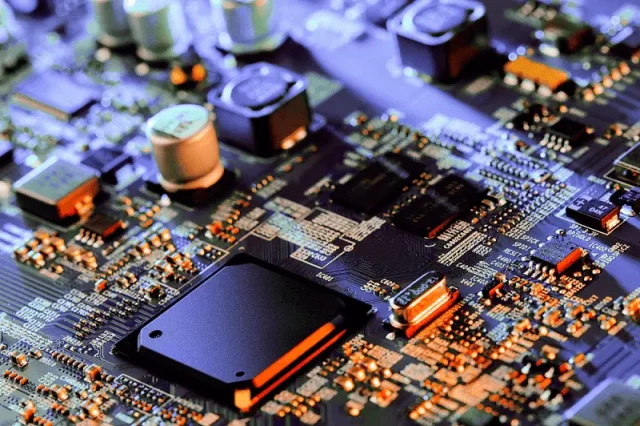

High TG materials are essential in modern PCB design where thermal performance, dimensional stability, and long-term reliability are critical. TG, or glass transition temperature, defines the point at which PCB substrates transition from a rigid to a more flexible state. Materials with high TG are engineered to maintain mechanical integrity, electrical performance, and impedance stability under elevated operating temperatures and repeated thermal cycling.

Material Characteristics of High TG Materials

High TG materials typically offer glass transition temperatures above 170°C, compared to standard FR-4 laminates that generally range around 130–140°C. This makes high TG materials suitable for applications such as high-layer-count PCBs, high-speed digital boards, RF modules, and automotive electronics.

Key characteristics include:

-

High glass transition temperature (TG) for thermal resilience

-

Low coefficient of thermal expansion (CTE) for mechanical stability

-

Stable dielectric constant (Dk) and low dissipation factor (Df) for signal integrity

-

Low moisture absorption to prevent delamination or warpage

These properties ensure that High TG PCB materials maintain consistent performance in harsh thermal environments.

Thermal and Mechanical Performance

Thermal management is a primary driver for selecting high TG materials. During reflow soldering or operation in high-temperature environments, PCBs may experience warpage, delamination, or mechanical stress. High TG materials reduce these risks by providing:

-

Structural rigidity during high-temperature processes

-

Stable mechanical performance in multilayer stackups

-

Reduced solder joint fatigue

-

Improved reliability under thermal cycling

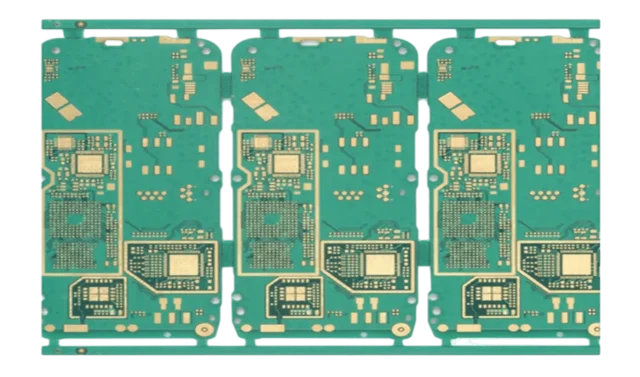

This is especially critical in high-layer-count PCBs, where uneven thermal expansion can create alignment and electrical reliability issues.

Electrical and Signal Integrity Advantages

High TG materials not only address mechanical stability but also support high-speed and RF signal performance. Maintaining a stable dielectric constant across temperature and frequency ranges is essential for controlled impedance routing and low-loss signal transmission.

Electrical advantages include:

-

Consistent impedance across multiple layers

-

Reduced signal distortion and reflection

-

Low insertion loss for high-speed traces

-

Stable performance in mixed-signal and RF applications

High TG materials are therefore suitable for 5G modules, satellite communication boards, and high-speed computing backplanes.

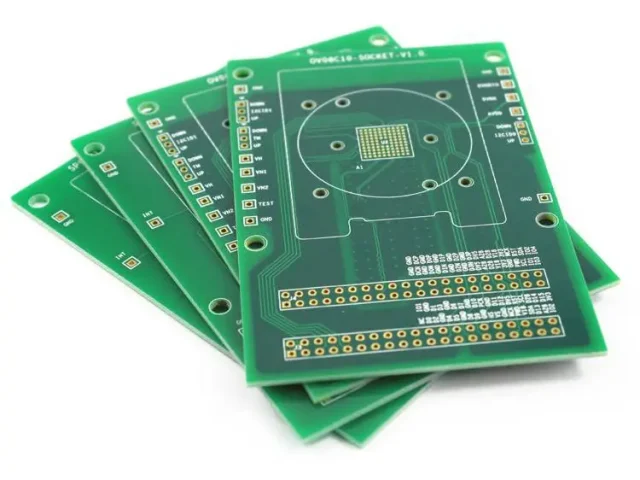

Manufacturing Considerations

Fabricating PCBs with high TG materials requires careful process control. Due to their increased rigidity and thermal resistance, manufacturing processes must accommodate:

-

Precise lamination to avoid voids or misalignment

-

Controlled drilling and via formation to prevent substrate cracking

-

Accurate etching for fine-line traces in multilayer stackups

-

Moisture and thermal management during storage and assembly

Proper process discipline ensures that the material’s high TG properties are fully leveraged in the final PCB assembly.

Application Domains

High TG materials are widely used in applications where thermal resilience, signal integrity, and mechanical reliability are critical:

-

Multilayer server and data center backplanes

-

High-speed digital and RF communication boards

-

Aerospace and defense electronics

-

Automotive electronics and EV power modules

-

Industrial automation and high-power electronics

Engineering Perspective

High TG PCB materials are a strategic engineering choice to meet the growing demands of high-speed, high-layer-count, and high-temperature PCB systems. By carefully selecting high TG laminates, engineers can maintain mechanical stability, reliable signal integrity, and long-term board performance even in harsh thermal environments.

KKPCB provides tailored high TG PCB solutions with engineering support for controlled impedance, thermal stability, and multilayer manufacturing precision.