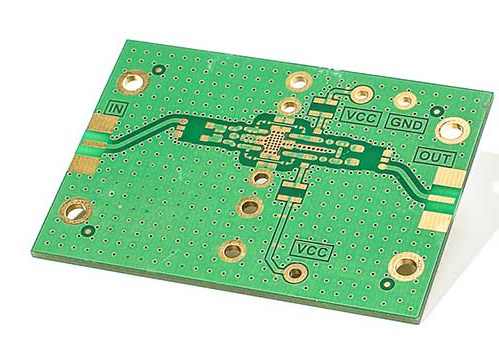

As integrated circuits continue to increase in complexity, the number of I/O connections per device has grown dramatically. The High Pin Count PCB is specifically engineered to accommodate dense signal routing, stable power delivery, and long-term reliability without compromising electrical performance.

A professionally designed high pin count PCB enables advanced systems to function reliably under demanding conditions.

What Is a High Pin Count PCB?

A High Pin Count PCB is a printed circuit board designed to support components with hundreds or thousands of pins, such as:

-

Large BGAs and fine-pitch packages

-

Advanced processors and ASICs

-

High-density connectors

These boards require specialized routing and manufacturing techniques.

Challenges in High Pin Count PCB Design

High pin count designs introduce several challenges:

-

Limited routing space

-

Increased risk of crosstalk and noise

-

Complex power distribution requirements

Overcoming these challenges requires advanced PCB technology and experience.

Advanced Routing Strategies

High pin count PCBs often use:

-

Fine-line trace and space

-

Blind and buried vias

-

Fan-out techniques for dense BGA packages

These strategies maximize routing efficiency while maintaining reliability.

Signal Integrity in High Pin Count PCBs

Maintaining signal integrity is critical. High pin count PCBs focus on:

-

Controlled impedance routing

-

Short and matched signal paths

-

Proper reference plane design

These measures reduce reflections and timing errors.

Power Integrity and Grounding

Dense pin configurations increase power demand. Solutions include:

-

Dedicated power and ground planes

-

Low-inductance decoupling networks

-

Optimized current return paths

Stable power delivery ensures consistent device operation.

Stackup and Material Selection

High pin count PCBs often require:

-

Multilayer stackups

-

High-Tg or low-loss materials

-

Symmetrical layer construction

Material and stackup choices affect both performance and manufacturability.

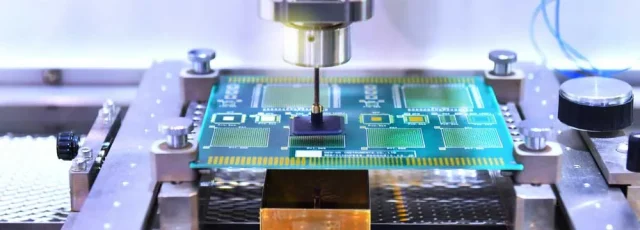

Manufacturing Precision and Yield Control

Fabricating high pin count PCBs requires:

-

Tight registration accuracy

-

Reliable via plating

-

Strict inspection and electrical testing

Process control ensures high yield and consistent quality.

Typical Applications of High Pin Count PCBs

High pin count PCBs are widely used in:

-

Semiconductor test systems

-

High-performance computing platforms

-

Networking and communication equipment

-

Advanced industrial electronics

Each application benefits from dense interconnect capability.

Choosing a High Pin Count PCB Manufacturer

When selecting a high pin count PCB supplier, consider:

-

Experience with dense and complex designs

-

Capability for fine-line and multilayer fabrication

-

Controlled impedance and testing support

-

Engineering collaboration during design review

A capable manufacturer minimizes risk and accelerates development.

Conclusion

The High Pin Count PCB enables the next generation of complex electronic systems by supporting dense interconnects, stable power delivery, and reliable signal integrity. With proper design and precise manufacturing, high pin count PCBs deliver consistent performance from prototype to production.

Working with an experienced high pin count PCB manufacturer ensures successful implementation of demanding designs.