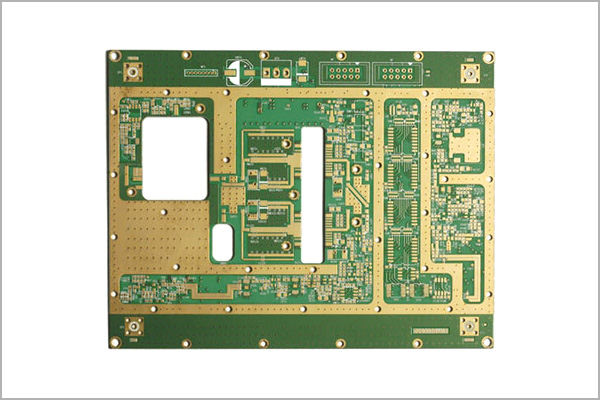

In RF, microwave, and high-speed electronic testing, even minor PCB imperfections can introduce significant measurement errors. The High Frequency Test PCB is engineered to serve as a neutral and stable signal platform, allowing engineers to evaluate devices and systems with confidence.

A properly designed high frequency test PCB ensures that test results reflect device performance—not PCB-induced distortion.

The Role of High Frequency Test PCBs in Validation

High frequency test PCBs are not functional products but precision measurement tools. Their primary purpose is to:

-

Preserve original signal characteristics

-

Eliminate unnecessary loss and reflection

-

Maintain consistency across repeated tests

This makes them critical in RF and high-speed validation environments.

Frequency Range and Design Considerations

High frequency test PCBs typically operate from:

-

Several hundred MHz

-

Multiple GHz

-

Up to mmWave frequencies

As frequency increases, PCB geometry, materials, and transitions become dominant factors in signal behavior.

Controlled Impedance as a Test Foundation

Impedance deviations directly affect test accuracy. High frequency test PCBs rely on:

-

Precisely calculated transmission line structures

-

Tight dielectric thickness control

-

Stable reference planes

Consistent impedance ensures accurate S-parameter and time-domain measurements.

Low-Loss Dielectrics and Surface Roughness Control

Material and copper quality significantly impact signal loss. High frequency test PCBs often use:

-

Low-Dk, low-Df laminates

-

Smooth copper foil for reduced conductor loss

-

Hybrid stackups for cost-sensitive designs

These choices minimize attenuation and phase distortion.

Via Transitions and RF Interconnect Optimization

Poorly designed vias introduce reflections and resonance. High frequency test PCBs implement:

-

Short via stubs or back-drilling

-

Grounded via fences near signal vias

-

Optimized launch structures

Clean transitions improve bandwidth and measurement repeatability.

Crosstalk and EMI Suppression

In dense test setups, unwanted coupling degrades accuracy. Effective solutions include:

-

Adequate signal spacing

-

Ground stitching vias

-

Shielded routing zones

Proper isolation ensures clean test data.

Stackup Symmetry and Mechanical Stability

Test PCBs must remain stable over time and temperature. Stackups are designed to:

-

Minimize warpage

-

Maintain consistent dielectric properties

-

Support precise connector alignment

Mechanical stability directly impacts test consistency.

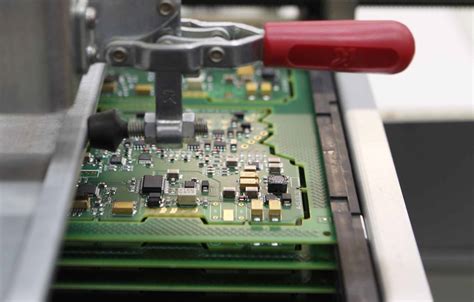

Manufacturing Accuracy and Validation

Producing high frequency test PCBs requires:

-

Tight process tolerances

-

Impedance coupon testing

-

Electrical and visual inspection

Manufacturing precision ensures that test boards perform as designed.

Typical Applications of High Frequency Test PCBs

High frequency test PCBs are widely used in:

-

RF and microwave component validation

-

5G and mmWave module testing

-

Semiconductor characterization

-

High-speed interface compliance testing

Each application demands predictable signal behavior.

Selecting a High Frequency Test PCB Manufacturer

When choosing a high frequency test PCB supplier, engineers should consider:

-

Experience with RF and microwave PCB fabrication

-

Controlled impedance and low-loss material capability

-

Support for prototype and engineering builds

-

Understanding of test-driven design priorities

The right partner helps ensure measurement integrity.

Conclusion

The High Frequency Test PCB plays a crucial role in accurate RF and microwave validation. By minimizing loss, reflection, and noise, it allows engineers to trust their test results and make informed design decisions.

Collaborating with an experienced high frequency test PCB manufacturer ensures reliable, repeatable, and high-precision test performance.