What Is a High Frequency Sensor PCB?

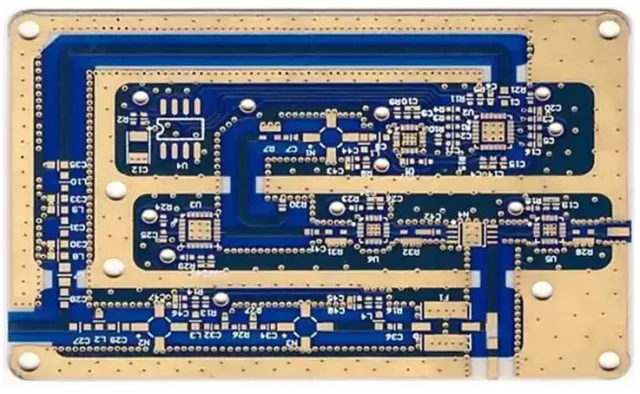

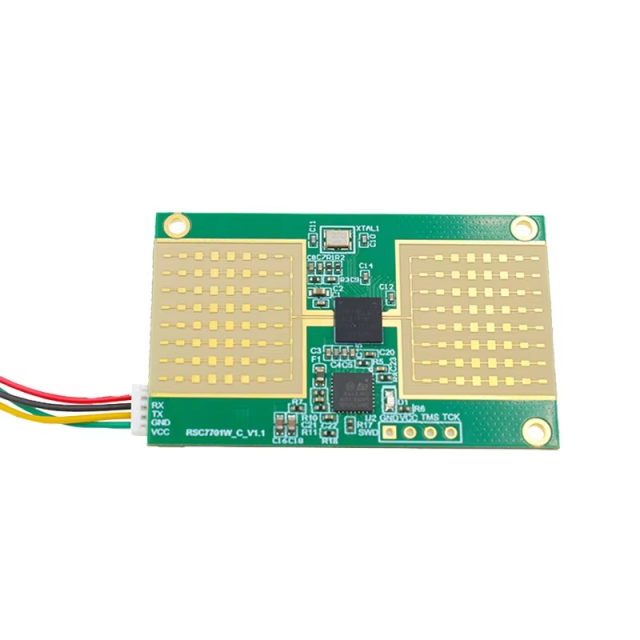

A High Frequency Sensor PCB is a precision printed circuit board used in sensor systems that operate at RF or high-frequency ranges, such as radar sensors, mmWave sensors, imaging sensors, and industrial sensing modules. These PCBs must support accurate signal transmission, low noise, and high measurement stability.

High Frequency Sensor PCBs are widely applied in automotive, industrial, medical, and communication sensor systems.

Key Requirements of High Frequency Sensor PCB

High-frequency sensor applications impose strict technical requirements on PCB design:

-

Low dielectric loss for high-frequency signals

-

Stable dielectric constant across frequency

-

Precise impedance controlled PCB structures

-

Excellent signal integrity and low noise

-

Reliable thermal and mechanical performance

Meeting these requirements is essential for sensor accuracy and repeatability.

Material Selection for High Frequency Sensor PCB

Choosing the right material is critical for High Frequency Sensor PCB performance. Common material options include:

-

Rogers RO4350B PCB

-

RF-35 PCB

-

Megtron 7 PCB

-

Hybrid PCB materials (RF + high-speed digital)

Low-loss laminates ensure minimal signal attenuation and phase distortion.

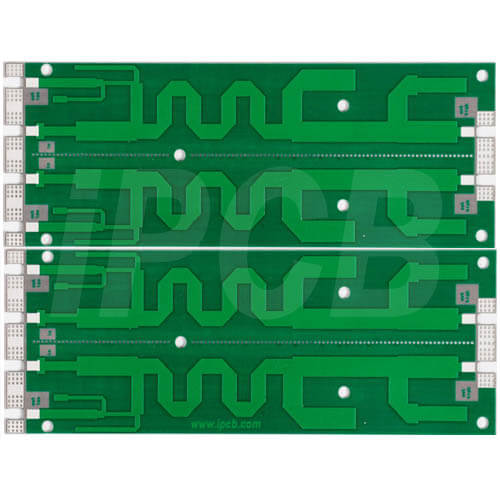

Impedance Control and Signal Integrity

Precise impedance controlled PCB design is mandatory for high-frequency sensor PCBs:

-

Controlled impedance transmission lines

-

Optimized stack-up design

-

Low-profile copper foil to reduce loss

-

Minimized via stubs and transitions

-

Careful grounding and shielding strategy

These techniques ensure clean and stable sensor signals.

Manufacturing Challenges for High Frequency Sensor PCB

Manufacturing a reliable High Frequency Sensor PCB requires advanced process capabilities:

-

Tight etching and registration tolerance

-

Accurate dielectric thickness control

-

High-precision drilling and via processing

-

Controlled copper roughness

-

RF performance and impedance testing

Experienced manufacturers are essential to achieve consistent quality.

Applications of High Frequency Sensor PCB

High Frequency Sensor PCBs are commonly used in:

-

Automotive radar and ADAS sensor modules

-

mmWave and RF sensor systems

-

Industrial sensing and automation

-

Medical imaging and diagnostic sensors

-

Wireless IoT and smart sensing devices

They are critical components in modern sensor technologies.

Conclusion

A High Frequency Sensor PCB enables accurate and reliable performance in advanced sensor systems by combining low-loss materials, precise impedance control, and high-quality manufacturing.

Partnering with a professional High Frequency Sensor PCB supplier ensures optimal signal integrity, stable performance, and reliable delivery from prototype to mass production.