As RF, microwave, and high-speed electronic systems continue to evolve, product complexity and performance requirements are increasing rapidly. High frequency PCB ODM services provide a complete solution by combining design expertise with advanced manufacturing, enabling customers to accelerate development while ensuring stable RF performance.

A professional high frequency PCB ODM partner bridges the gap between concept, engineering, and mass production.

What Is High Frequency PCB ODM?

High frequency PCB ODM (Original Design Manufacturing) refers to a service model where the manufacturer supports both PCB design and fabrication, specifically for high-frequency and high-speed applications.

Unlike standard PCB fabrication, a high frequency PCB ODM partner:

-

Participates in RF and high-speed design decisions

-

Recommends suitable low-loss materials

-

Optimizes stackups for impedance and signal integrity

-

Manufactures and tests PCBs under one integrated system

This approach reduces design risk and improves overall product performance.

Why Choose High Frequency PCB ODM Services?

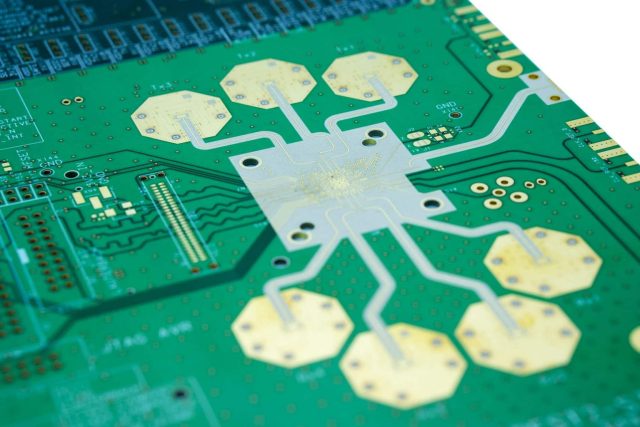

Design for RF Performance

High-frequency circuits are highly sensitive to layout, impedance, and material selection. An experienced high frequency PCB ODM team provides:

-

RF layout optimization

-

Impedance calculation and simulation

-

Stackup and grounding strategy design

This ensures signal integrity from the earliest design stage.

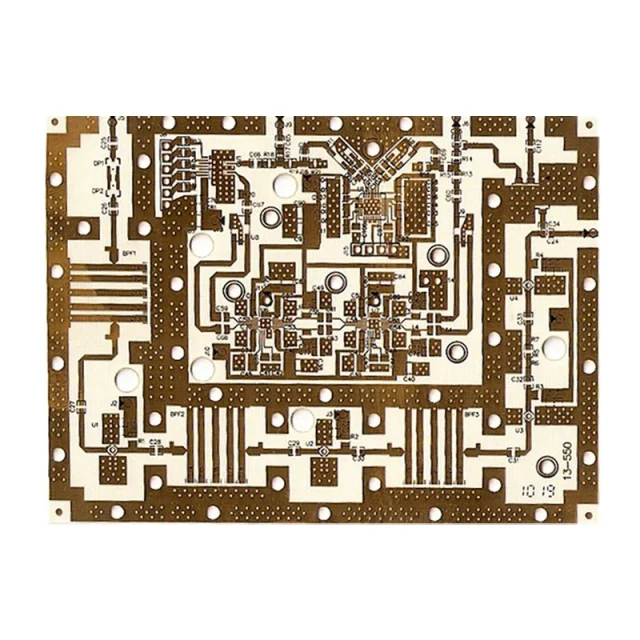

Material Expertise for High Frequency Applications

A reliable high frequency PCB ODM supports a wide range of RF materials, including:

-

Rogers series laminates

-

PTFE and Duroid materials

-

Low-loss hybrid stackups

-

High-Tg FR-4 for mixed-signal designs

Correct material selection directly impacts insertion loss, phase stability, and thermal reliability.

Controlled Impedance and Signal Integrity

High frequency PCB ODM manufacturing emphasizes precise impedance control:

-

Tight tolerance control on dielectric thickness

-

Accurate copper geometry management

-

Controlled impedance fabrication (±5% or better)

-

TDR testing and validation

These processes minimize signal reflection and ensure consistent RF performance.

Manufacturing Integration Advantages

By combining design and fabrication, high frequency PCB ODM services deliver:

-

Faster design iterations

-

Fewer engineering change orders (ECOs)

-

Higher first-pass yield

-

Smoother transition from prototype to mass production

Integrated workflows improve efficiency and product reliability.

Applications of High Frequency PCB ODM

High frequency PCB ODM services are widely used in:

-

RF front-end modules

-

5G and mmWave communication systems

-

Automotive radar and ADAS electronics

-

High-speed data transmission hardware

-

Industrial RF and sensing systems

-

Advanced IoT and wireless devices

These applications require stable high-frequency performance and repeatable manufacturing quality.

Prototype to Mass Production Support

A qualified high frequency PCB ODM partner supports the full product lifecycle:

-

Small-batch PCB prototypes

-

Engineering validation builds

-

Pilot runs and DFM optimization

-

Scalable mass production

This continuity ensures consistent electrical performance across all production stages.

Choosing the Right High Frequency PCB ODM Partner

When selecting a high frequency PCB ODM, evaluate:

-

RF and high-speed design experience

-

Material and stackup expertise

-

Controlled impedance and RF testing capability

-

Proven manufacturing quality systems

-

Clear communication between design and production teams

A strong ODM partner functions as an extension of your engineering team.

Conclusion

High frequency PCB ODM services provide a powerful solution for companies developing RF and high-speed electronic products. By integrating design expertise, material knowledge, and precision manufacturing, an experienced ODM partner reduces development risk, shortens time to market, and ensures stable high-frequency performance.

Choosing the right high frequency PCB ODM partner is a strategic decision that directly impacts product reliability and long-term success.