A professional High Frequency PCB ODM provides complete, end-to-end solutions covering PCB design, material selection, fabrication, and validation for RF, microwave, and high-speed electronic systems. As frequencies continue to increase in applications such as 5G communication, mmWave modules, radar systems, and high-speed networking, traditional PCB manufacturing alone is no longer sufficient.

High frequency PCB ODM services help customers reduce development risk, shorten time-to-market, and achieve stable signal performance through integrated engineering and manufacturing support.

What Is High Frequency PCB ODM?

High Frequency PCB ODM refers to an original design and manufacturing service focused on printed circuit boards operating at high frequencies. Unlike standard PCB suppliers, ODM providers participate in early-stage design, offering expertise in RF layout, impedance control, material selection, and stack-up optimization.

By combining design and manufacturing under one roof, high frequency PCB ODM ensures better electrical performance and production consistency.

Advantages of High Frequency PCB ODM Services

Choosing a High Frequency PCB ODM partner offers several key benefits:

-

Integrated RF PCB design and manufacturing

-

Optimized signal integrity and impedance control

-

Reduced design iterations and faster validation

-

Improved consistency from prototype to mass production

-

Lower total development and manufacturing cost

These advantages are especially valuable for complex RF and microwave designs.

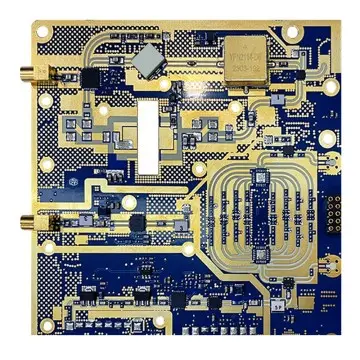

Material Expertise in High Frequency PCB ODM

Material selection is critical in high frequency PCB design. A qualified High Frequency PCB ODM provides in-depth knowledge of low-loss and high-frequency laminates.

Common materials include:

-

Rogers RO4003C, RO4350B, RO4835

-

RT/duroid 5880 and 6010

-

Taconic RF-35, TLY-5

-

Hybrid stack-ups combining low-loss materials with high-Tg FR-4

Proper material selection ensures stable dielectric properties and minimal signal loss.

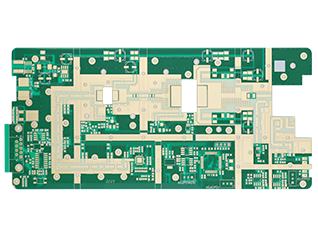

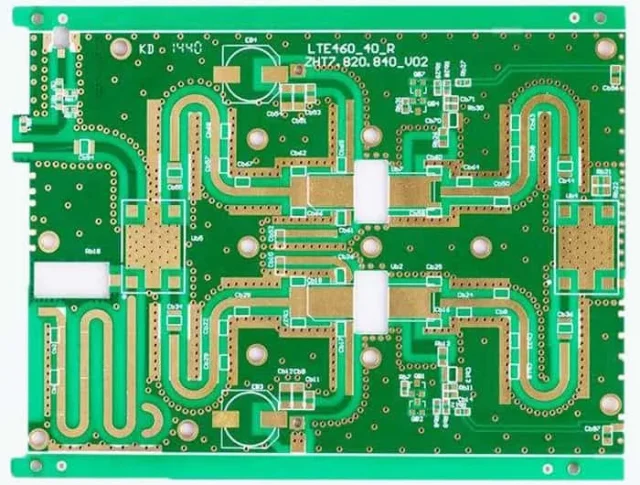

Key Manufacturing Capabilities

High frequency PCB ODM services require advanced fabrication technologies and strict process control:

-

Controlled impedance PCB manufacturing

-

Precision multilayer and hybrid lamination

-

Fine line etching for RF trace accuracy

-

Laser drilling and microvia technology

-

RF-optimized surface finishes (ENIG, immersion silver)

-

Impedance and electrical performance verification

These capabilities ensure reliable high-frequency PCB performance.

Design Support and Engineering Collaboration

A professional High Frequency PCB ODM provides comprehensive engineering support throughout the project lifecycle:

-

RF layout and stack-up design optimization

-

Signal integrity and impedance simulation

-

DFM and DFT analysis

-

Antenna and RF structure integration

-

EMI and grounding optimization

Close collaboration between design and manufacturing teams improves first-pass success rates.

Applications of High Frequency PCB ODM

High frequency PCB ODM solutions are widely used in:

-

5G communication modules and base stations

-

RF transceivers and antenna systems

-

mmWave and radar modules

-

Automotive ADAS and radar electronics

-

Satellite and aerospace communication systems

-

High-speed data center and networking equipment

In these applications, ODM support ensures reliable and scalable PCB solutions.

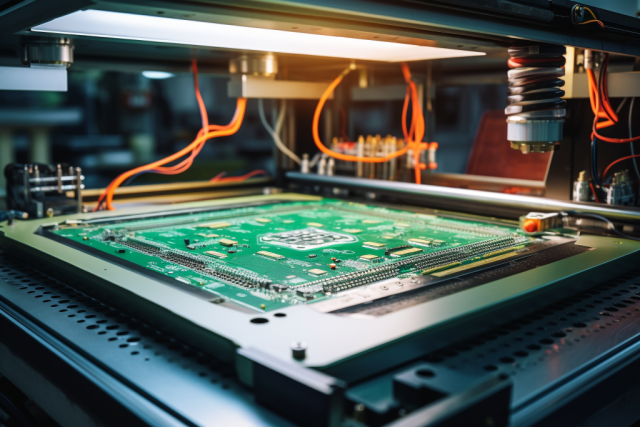

From Prototype to Mass Production

High frequency PCB ODM services typically begin with prototype development to validate RF performance and impedance accuracy. Once confirmed, the same design and manufacturing processes are scaled to volume production, ensuring consistent quality and long-term reliability.

Working with a single ODM partner reduces handover risks and simplifies supply chain management.

Conclusion

A professional High Frequency PCB ODM is a strategic partner for developing advanced RF, microwave, and high-speed electronic systems. By integrating design expertise, material knowledge, and advanced manufacturing capabilities, ODM providers deliver optimized PCB solutions that meet demanding performance requirements.

As high-frequency technologies continue to evolve, choosing an experienced High Frequency PCB ODM becomes essential for achieving reliable performance, faster development cycles, and scalable production.