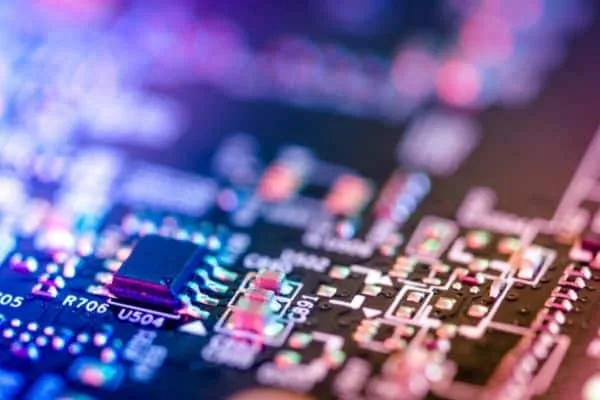

In today’s fast-paced electronics industry, speed can determine market success. Fast delivery PCBs offer engineers and manufacturers the ability to accelerate prototyping, testing, and low-volume production without compromising quality or electrical performance.

Fast delivery PCB services are essential for time-sensitive projects, including high-frequency, high-speed, and complex multilayer designs.

What Is a Fast Delivery PCB?

A fast delivery PCB is a printed circuit board manufactured and delivered within an accelerated timeline, often ranging from 24 hours for prototypes to a few days for small batch production. These boards are ideal for:

-

Engineering prototypes

-

Small batch validation

-

Quick-turn NPI (New Product Introduction) projects

Fast delivery PCBs combine speed with quality and reliability.

Key Advantages of Fast Delivery PCBs

Fast delivery PCB solutions provide several benefits:

-

Rapid Prototyping: Shorten design-to-test cycles, allowing engineers to iterate faster.

-

Small Batch Production: Validate designs under real-world conditions before mass production.

-

Reduced Time-to-Market: Deliver boards quickly to meet tight project deadlines.

-

Flexible Manufacturing: Support high-frequency, multilayer, and controlled impedance designs.

Maintaining Quality at Speed

Even with accelerated timelines, high-quality standards are critical. Fast delivery PCBs are manufactured with:

-

Accurate layer alignment and multilayer lamination

-

Controlled impedance and low-loss materials

-

Precision drilling and high-density interconnects

-

Automated optical inspection (AOI) and electrical testing

This ensures reliability and signal integrity for high-speed, RF, and sensitive test applications.

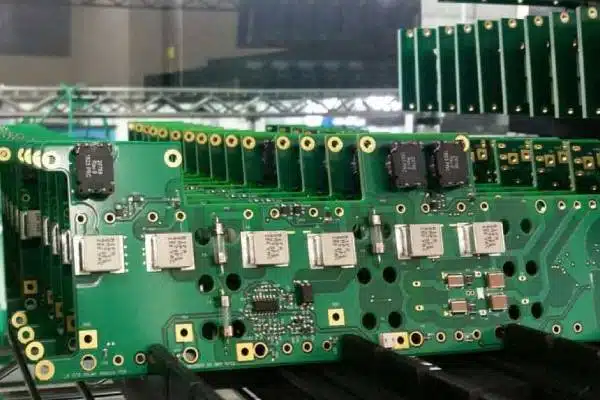

Applications of Fast Delivery PCBs

Fast delivery PCBs are widely used in:

-

Rapid prototyping for electronics startups and R&D

-

Engineering validation and testing of high-speed circuits

-

ATE and semiconductor test boards

-

Small batch production for pilot programs

These applications benefit from both speed and performance.

Choosing a Fast Delivery PCB Manufacturer

When selecting a fast delivery PCB supplier, consider:

-

Turnaround times for prototypes and small batches

-

Experience with multilayer, high-speed, and RF PCBs

-

Quality control and process reliability

-

Flexible support for design changes and revisions

A capable partner ensures quick delivery without compromising electrical or mechanical performance.

Conclusion

Fast delivery PCBs enable engineers and manufacturers to accelerate product development while maintaining high-quality standards. With rapid prototyping, small batch production, and reliable manufacturing, fast delivery PCBs are the key to shortening time-to-market and enhancing project agility.

Partnering with an experienced fast delivery PCB manufacturer ensures speed, reliability, and precision from prototype to production.