In today’s fast-paced electronics market, time-to-market is critical. Fast delivery PCBs provide a solution for engineers and manufacturers who need quick turnaround without compromising quality. Whether for prototyping, small batch production, or urgent project deadlines, fast delivery PCB services help accelerate product development cycles and engineering iterations.

What Is a Fast Delivery PCB?

A fast delivery PCB is a printed circuit board manufactured and delivered within a significantly shorter lead time than standard production. These PCBs can range from single-layer prototypes to complex multilayer, high-speed boards, and are designed to meet both electrical performance and mechanical reliability requirements.

Key features include:

-

Quick fabrication and assembly

-

Controlled impedance for high-speed signals

-

Reliable solder mask and surface finish quality

-

Flexible quantity from single prototypes to small batch runs

Why Fast Delivery PCBs Are Important

Fast delivery PCBs address several common development challenges:

-

Accelerate product validation and design iteration

-

Support rapid engineering prototyping and testing

-

Reduce project delays and shorten time-to-market

-

Enable early detection of design flaws before mass production

By speeding up delivery, engineers can iterate faster and reduce costly development cycles.

Design Considerations for Fast Delivery PCBs

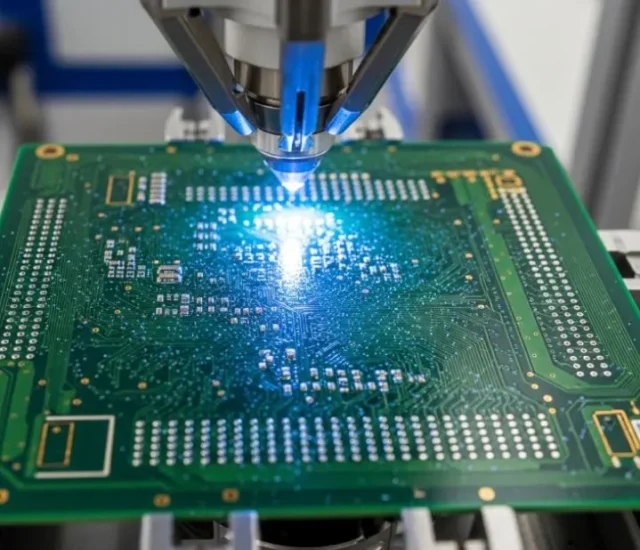

Even with rapid manufacturing, high-quality standards must be maintained. Fast delivery PCBs require careful attention to:

-

Controlled impedance for signal integrity

-

Stackup planning for multilayer boards

-

High pin count and fine-pitch routing

-

Material selection suitable for high-speed or high-frequency designs

Balancing speed and quality ensures reliable performance for prototypes and small batches.

Applications of Fast Delivery PCBs

Fast delivery PCBs are ideal for:

-

Rapid prototyping of high-speed electronics

-

Small batch production for pilot runs

-

Testing and validation of complex circuits

-

Engineering iteration and functional verification

These applications benefit from reduced lead times without sacrificing electrical or mechanical reliability.

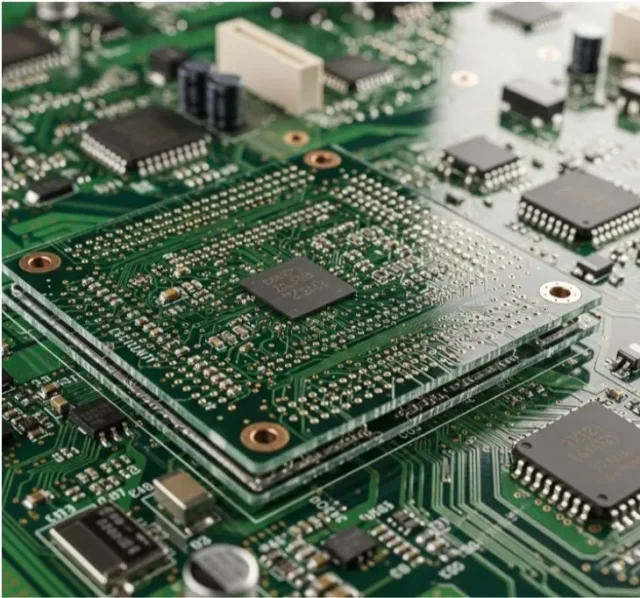

Choosing a Fast Delivery PCB Supplier

When selecting a fast delivery PCB supplier, consider:

-

Proven ability to meet short lead times consistently

-

Experience with high-speed, high-density, and multilayer PCBs

-

Quality assurance and controlled impedance verification

-

Support for prototyping, small batch, and volume production

A reliable partner ensures that fast delivery doesn’t compromise PCB quality or performance.

Conclusion

Fast delivery PCBs are a strategic advantage for modern electronics development, enabling engineers to prototype, test, and iterate designs faster than ever. By combining rapid turnaround with precise manufacturing and reliable quality, fast delivery PCBs accelerate engineering workflows and reduce time-to-market.

Partnering with a professional fast delivery PCB manufacturer ensures speed, quality, and consistency from prototype to small batch production.