1. Engineering Overview / Abstract

As precision RF test and measurement systems extend into the 40 – 110 GHz range, achieving sub-degree phase accuracy and minimal insertion-loss drift becomes a primary design requirement.

Taconic RF-35 PCBs—engineered with a glass-reinforced PTFE composite (Dk = 3.50 ± 0.05, Df = 0.0018 @ 10 GHz)—enable calibration-grade impedance consistency and low-loss performance across temperature cycles.

KKPCB integrates advanced lamination control and inline RF verification to ensure that the theoretical dielectric uniformity of RF-35 translates directly into real-world metrology stability.

2. Engineering Context & Technical Challenges

In precision VNA calibration modules, power-sensor backplanes, and mmWave fixtures built on Taconic RF-35 PCB substrates, even slight dielectric fluctuation or copper-roughness variation can distort S-parameters and cause calibration drift.

| Design Challenge | Root Cause | Engineering Impact |

|---|---|---|

| Phase instability | Dk variation vs temperature | Calibration reference error |

| Insertion-loss variation | Copper roughness and etch tolerance | Amplitude imbalance |

| Impedance mismatch | Lamination skew or resin-rich zones | Return-loss degradation |

| Connector fatigue | Repetitive coupling cycles | Microcrack formation → impedance shift |

These issues directly affect repeatability and traceability of RF test results, where the Taconic RF-35 PCB’s dielectric stability is fundamental to ensuring calibration integrity.

3. Material Science and Performance Characteristics

Taconic RF-35 offers an excellent trade-off between mechanical strength and RF loss performance.

-

Dk = 3.50 ± 0.05, Df = 0.0018 @ 10 GHz

-

CTE (Z-axis): ~ 35 ppm/°C, ensuring copper-PTFE alignment

-

Thermal Conductivity: 0.25 W/m·K

Compared with FR-4 (Df ≈ 0.018), RF-35 exhibits nearly 90 % lower loss tangent, enabling more stable insertion-loss response up to 110 GHz.

This makes it ideal for calibration standards and high-linearity mmWave reference boards.

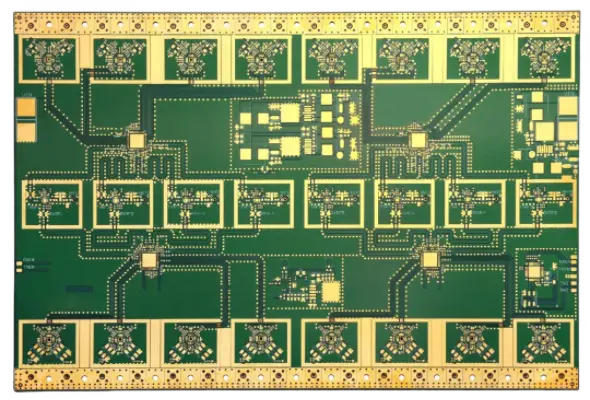

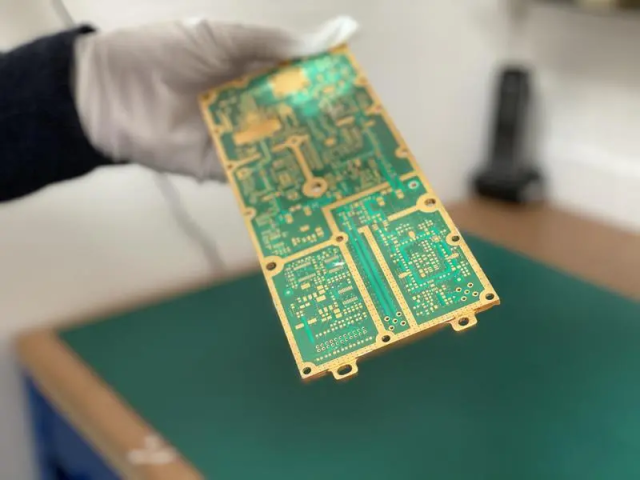

4. KKPCB Engineering Case Study — VNA Calibration Module

Client & Application

Japanese RF instrumentation manufacturer seeking sub-1° phase stability for VNA calibration fixtures.

Engineering Problem

Legacy PTFE boards showed 1.8° phase drift after 500 thermal cycles, exceeding calibration tolerance.

-

Implemented vacuum lamination with controlled resin flow (± 8 µm thickness tolerance)

-

Applied ½ oz rolled copper (Ra < 0.8 µm) for low surface loss

-

Integrated inline VNA verification per panel (10 – 110 GHz)

| Parameter | Target | KKPCB Result |

|---|---|---|

| Phase Deviation | < 1° @ 50 GHz | 0.78° |

| Insertion Loss | < 0.30 dB/in | 0.27 dB/in |

| Return Loss | > 15 dB | 16.8 dB |

| Connector Endurance | 1000 cycles | Pass (no impedance shift) |

Outcome: Phase drift reduced by 56 % vs legacy boards, ensuring calibration repeatability across production lots.

5. Stackup Design & RF Implementation

KKPCB employed a 4-layer hybrid RF-35 + FR-408 core with balanced CTE stackup.

-

Controlled copper roughness (Ra < 1.0 µm)

-

Impedance tolerance ± 5 Ω across layers

-

HFSS simulation validated phase uniformity < 1° @ 50 GHz

-

Inline TDR scanning ensured trace-to-trace variance < 2 %

This configuration enables reliable high-frequency referencing within precision test systems, maintaining amplitude balance and low-loss coupling.

6. Environmental & Reliability Validation

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | –55 °C ↔ +150 °C, 1000 cycles | No delamination; phase shift < 0.2° |

| Humidity Aging | 85 °C / 85 % RH, 1000 h | Df drift < 0.0001 |

| Mechanical Fatigue | Connector 500 cycles | No impedance deviation |

| Flatness Deviation | Post-lamination < 0.1 mm / 250 mm | Pass |

These validation results confirm that Taconic RF-35 PCBs maintain structural and RF stability under harsh environmental stresses typical of test laboratories.

7. Conclusion — Engineering Reliability Integration

The Taconic RF-35 PCB platform provides a robust dielectric foundation for metrology-grade RF applications.

Through KKPCB’s precision lamination and inline calibration framework, designers achieve stable insertion loss, controlled impedance, and phase consistency across wide temperature ranges.

This ensures long-term measurement reliability and traceable accuracy for advanced RF test systems.

8. Contact / CTA

Contact KKPCB Engineering Team for customized stackup design, impedance verification, and phase-stability validation using Taconic RF-35 PCBs for RF measurement, 5G modules, and aerospace communication applications.