Rigid-Flex PCB: Integrating Mechanical Flexibility with Rigid PCB Performance

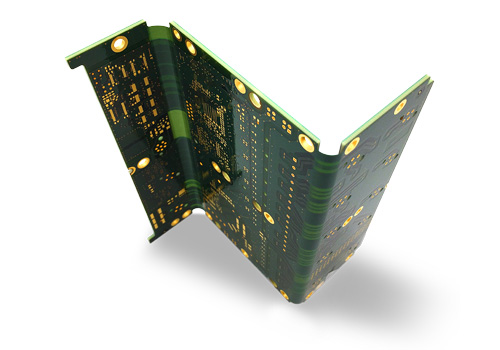

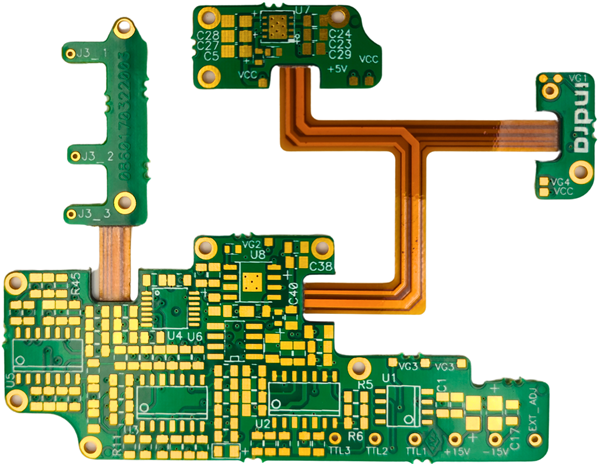

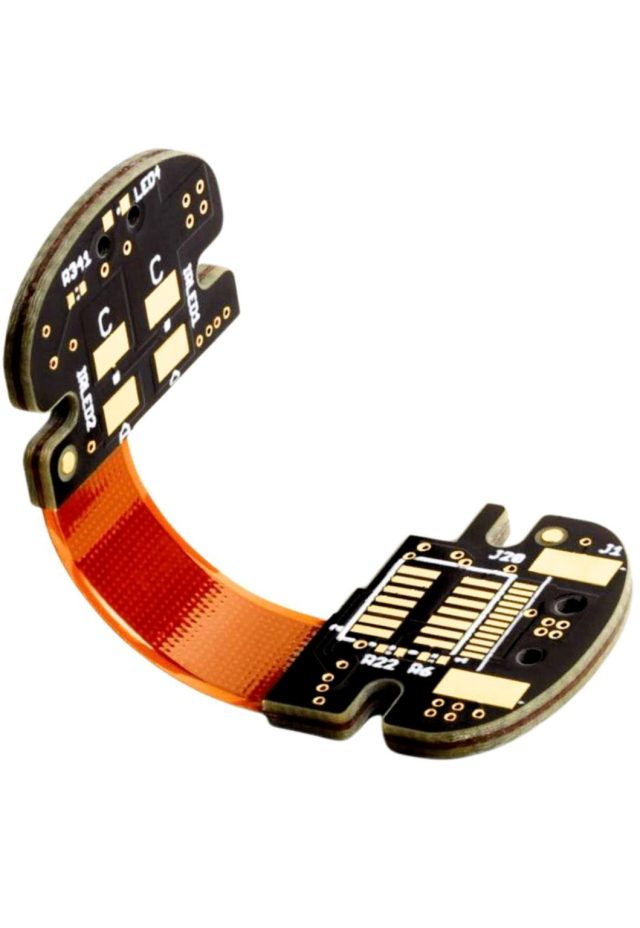

A Rigid-Flex PCB is a hybrid printed circuit board that combines rigid PCB sections and flexible circuits into a single integrated structure. By embedding flexible polyimide layers between rigid FR-4 or high-performance laminates, Rigid-Flex PCB architectures eliminate connectors, reduce interconnect failures, and enable compact three-dimensional electronic assemblies.

Rigid-Flex PCB technology has become a preferred solution for electronics requiring high reliability, space optimization, vibration resistance, and complex mechanical integration.

Why Rigid-Flex PCB Is Critical for Modern Electronic Systems

Traditional designs rely on separate rigid boards connected by cables or connectors, which introduce signal loss, mechanical failure points, and assembly complexity. A Rigid-Flex PCB consolidates these elements into one unified structure.

Key advantages of Rigid-Flex PCB designs include:

-

Reduced connector count and interconnect loss

-

Improved signal integrity across moving or folded sections

-

Higher mechanical reliability under vibration and shock

-

Compact and lightweight system architecture

-

Simplified assembly and improved yield

By integrating electrical and mechanical design, Rigid-Flex PCBs enable system-level optimization rather than board-level compromises.

Signal Integrity Benefits of Rigid-Flex PCB Structures

High-speed and high-frequency signals are sensitive to impedance discontinuities introduced by connectors and cables. Rigid-Flex PCB technology significantly improves signal integrity by maintaining continuous copper traces across rigid and flex regions.

From an electrical perspective, Rigid-Flex PCBs provide:

-

Stable controlled impedance across rigid-to-flex transitions

-

Reduced reflection and insertion loss

-

Improved phase consistency for high-speed interfaces

-

Lower EMI risk compared to cable-based interconnections

-

Better grounding continuity across mechanical folds

These characteristics make Rigid-Flex PCB designs ideal for high-speed digital, RF, and mixed-signal applications.

Mechanical Reliability Advantages of Rigid-Flex PCB Designs

Mechanical stress is one of the leading causes of PCB failure in harsh environments. Rigid-Flex PCB constructions are engineered to absorb stress through flexible regions while protecting rigid component areas.

Key mechanical advantages include:

-

High resistance to vibration and repetitive bending

-

Reduced solder joint stress compared to rigid boards

-

Improved shock resistance in portable and mobile devices

-

Longer product lifespan under dynamic mechanical loads

Because flex layers are designed with controlled bend radius and copper grain orientation, Rigid-Flex PCBs maintain long-term reliability even in moving assemblies.

Rigid-Flex PCB Stackup and Material Engineering

Designing a reliable Rigid-Flex PCB stackup requires careful material selection and layer transition control.

Typical Rigid-Flex PCB stackup considerations include:

-

Polyimide dielectric for flex layers

-

Rolled annealed copper for improved flex endurance

-

FR-4, high-Tg, or low-loss laminates for rigid sections

-

Adhesiveless constructions for improved thermal reliability

-

Controlled coverlay thickness for mechanical protection

Proper stackup symmetry and copper balance are critical to prevent warpage and ensure dimensional stability in Rigid-Flex PCB manufacturing.

Manufacturing Complexity of Rigid-Flex PCBs

Fabricating a Rigid-Flex PCB is significantly more complex than producing standard rigid boards. It requires tight process control across multiple fabrication stages.

Key manufacturing challenges include:

-

Precision laser or mechanical routing of flex areas

-

Accurate alignment between rigid and flexible layers

-

Controlled lamination pressure to protect flex regions

-

Coverlay application and curing consistency

-

Electrical testing across dynamic interconnect paths

Because errors cannot be reworked easily, Rigid-Flex PCB fabrication demands advanced equipment, experienced engineering, and rigorous quality inspection.

Thermal and Reliability Performance of Rigid-Flex PCB

Rigid-Flex PCB designs can be optimized for thermal performance by integrating internal copper planes and thermal paths within rigid sections while maintaining flexibility elsewhere.

Reliability advantages include:

-

Improved thermal cycling performance

-

Reduced failure points from eliminated connectors

-

Stable electrical performance over temperature extremes

-

Long-term durability in mission-critical applications

These properties make Rigid-Flex PCBs suitable for environments where mechanical and thermal stresses coexist.

Applications of Rigid-Flex PCB Technology

Rigid-Flex PCBs are widely used in applications requiring compact design and high reliability, including:

-

Aerospace and avionics systems

-

Medical devices and implantable electronics

-

Automotive ADAS and in-vehicle electronics

-

Industrial automation and robotics

-

Wearable electronics and IoT devices

In these applications, Rigid-Flex PCB solutions enable innovative product form factors while maintaining electrical integrity.

KKPCB Rigid-Flex PCB Capabilities

KKPCB offers full-spectrum Rigid-Flex PCB engineering and manufacturing services, including:

-

Custom rigid-flex stackup design and DFM support

-

Adhesiveless and high-reliability constructions

-

Controlled impedance rigid-flex routing

-

High-layer-count rigid-flex PCB fabrication

-

Prototype to volume production scalability

Every Rigid-Flex PCB produced by KKPCB is engineered to meet strict electrical, mechanical, and reliability requirements.

Conclusion

A Rigid-Flex PCB enables compact integration, superior signal integrity, and exceptional mechanical reliability by combining rigid and flexible technologies into a single platform. As electronic systems become smaller, faster, and more mechanically complex, Rigid-Flex PCB architectures provide a decisive engineering advantage.

KKPCB delivers reliable Rigid-Flex PCB solutions through advanced materials, precision manufacturing, and deep engineering expertise—supporting next-generation electronic systems from concept to production.