Introduction

In modern power electronics design, effective thermal management is essential to ensure system reliability and long-term performance.

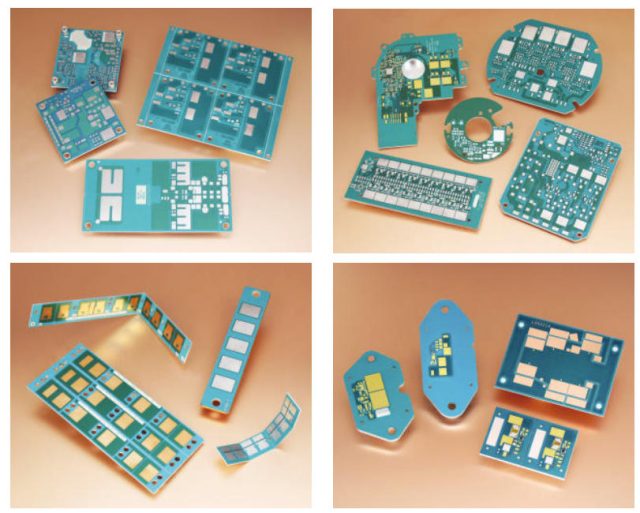

Bergquist Thermal Clad® laminates, engineered by Henkel, are high-performance substrates that provide exceptional heat dissipation, robust electrical insulation, and superior mechanical stability.

These materials are widely used in LED lighting, automotive electronics, power supplies, motor drives, and industrial control systems — offering a reliable foundation for high-power and high-temperature circuit applications.

This guide provides a complete overview of Thermal Clad® material types, their structure, properties, and selection guidelines for engineers and designers seeking the best balance between thermal performance, cost, and reliability.

Key Components of Thermal Clad® Laminates

1. Dielectric Layer

-

Acts as an electrical insulator between the conductive copper layer and the base metal.

-

Critical to both thermal conductivity and dielectric breakdown voltage.

-

Typical dielectric thicknesses: 50 μm – 150 μm, optimized for thermal performance and insulation strength.

2. Base Metal

-

Common materials: Aluminum and Copper.

-

Aluminum provides an excellent cost-to-performance ratio.

-

Copper offers superior heat spreading for demanding high-power applications.

-

Standard thicknesses: 1.0 mm, 1.5 mm, 2.0 mm, depending on mechanical and thermal requirements.

3. Circuit Layer

-

Typically copper foil, where the electrical circuit is etched.

-

Available in thicknesses from 35 μm to 140 μm to meet current-carrying demands.

-

Provides high reliability during reflow soldering and thermal cycling.

Thermal Clad® Material Categories

| Category | Key Features | Typical Applications | Example Grades |

|---|---|---|---|

| High Thermal Conductivity (HTC) | Up to 3.0 W/m·K, optimized for high heat flux | High-power LED, motor drives, power modules | HT-04503, HTC Series |

| Standard Thermal Conductivity | Balanced thermal/electrical performance | Consumer electronics, automotive lighting | SC Series |

| High-Temperature | Stable beyond 150°C operating temp | Engine control units, power converters | HT-04503 |

| Flexible Thermal Clad® | Bendable base material for 3D designs | Flexible LED strips, wearables | F-Series |

| Thin Dielectric | Low thermal resistance for miniaturized systems | Mobile devices, compact sensors | TD-Series |

Thermal Clad® Material Selection Criteria

-

Thermal Conductivity

Select according to heat generation and system cooling design. -

For example: High-power LEDs may require >2.0 W/m·K thermal conductivity.

-

Dielectric Breakdown Voltage

Ensure safe insulation; typical range 1 kV – 5 kV depending on dielectric thickness. -

Operating Temperature

Use high-temperature laminates in environments exceeding 150°C. -

Current-Carrying Capability

Match copper thickness to circuit current load; 70 μm or more for high-current designs. -

Mechanical Strength

Select base metal thickness for rigidity and vibration resistance. -

Cost vs. Performance Optimization

-

Use standard conductivity grades for cost-sensitive consumer devices.

-

Choose HTC or high-temp materials for mission-critical automotive or industrial systems.

-

Common Applications and Recommended Materials

| Application | Recommended Material | Key Design Requirements |

|---|---|---|

| High-Power LED Lighting | HTC Series, HT-04503 | High heat transfer, long lifespan |

| Automotive Electronics | HT-04503, High-Temperature Series | Stable under thermal cycling, high reliability |

| Power Modules | HTC Series | Maximum thermal dissipation, minimal dielectric loss |

| Consumer Electronics | Standard Thermal Conductivity | Cost-efficient, reliable insulation |

| Industrial Controls | High Thermal Conductivity | Long-term durability, efficient cooling |

| Flexible Circuits | Flexible Thermal Clad® | Bendable, low-profile structure |

Fabrication and Assembly Guidelines

-

Cutting:

Use precision tools to prevent dielectric delamination. -

Drilling:

Employ sharp bits and controlled speeds to minimize cracking. -

Soldering:

Observe material-specific reflow limits to avoid thermal degradation. -

Assembly:

Apply heat sinks or thermal vias for enhanced thermal performance.

Advantages of Bergquist Thermal Clad® Laminates

✅ Superior Heat Dissipation — Transfers heat efficiently from components to metal base.

✅ Reliable Electrical Insulation — High dielectric strength ensures circuit safety.

✅ Compact and Lightweight — Enables smaller, thermally efficient PCB designs.

✅ Cost Efficiency — Reduces the need for additional heat spreaders or substrates.

✅ Design Flexibility — Available in multiple configurations for rigid, flexible, or high-temp use cases.

Conclusion

Bergquist Thermal Clad® laminates represent one of the most trusted material technologies in thermal management for power electronics. Their advanced material engineering ensures high reliability, consistent performance, and cost-effective production across multiple industries.

For detailed datasheets, thermal simulation data, and processing recommendations, refer to the official Bergquist Thermal Clad® technical documentation or contact your PCB manufacturer for material compatibility and stack-up design support.