What Is a Ceramic PCB?

A Ceramic PCB is a high-performance printed circuit board manufactured using ceramic substrate materials such as Alumina (Al₂O₃), Aluminum Nitride (AlN), or Beryllium Oxide (BeO).

Unlike traditional FR-4 PCBs, Ceramic PCBs provide:

-

Excellent thermal conductivity

-

High mechanical strength

-

Superior electrical insulation

-

Stable performance in extreme environments

Ceramic PCB technology is widely used in high power electronics, automotive systems, LED lighting, RF modules, aerospace equipment, and industrial control systems.

Types of Ceramic PCB Materials

Different Ceramic PCB materials offer different advantages:

Alumina Ceramic PCB (Al₂O₃)

-

Most common ceramic PCB material

-

Good electrical insulation

-

Moderate thermal conductivity

-

Cost-effective for industrial applications

Aluminum Nitride Ceramic PCB (AlN)

-

Very high thermal conductivity (up to 170 W/mK)

-

Excellent heat dissipation

-

Ideal for high power modules

-

Used in power semiconductor packaging

Beryllium Oxide (BeO) Ceramic PCB

-

Extremely high thermal conductivity

-

Used in specialized RF and military applications

Selecting the right Ceramic PCB material depends on power density, thermal requirements, and reliability standards.

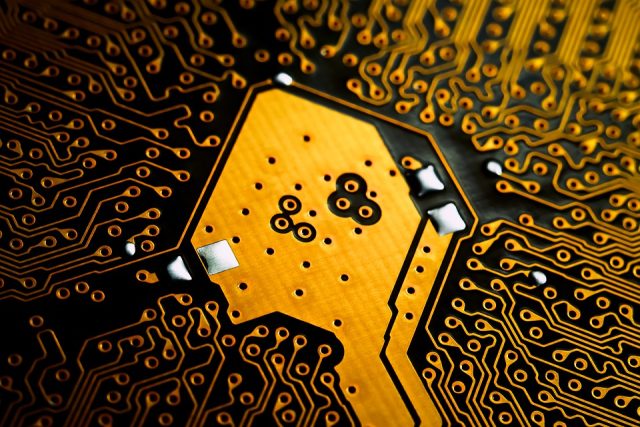

Advantages of Ceramic PCB

Ceramic PCB technology offers significant benefits compared to standard PCB materials:

-

High thermal conductivity for efficient heat dissipation

-

Low thermal expansion coefficient (CTE)

-

Excellent high temperature resistance

-

High voltage insulation capability

-

Stable dielectric performance

-

Long-term reliability in harsh environments

For high current PCB, power module PCB, LED PCB, and RF power amplifier PCB, Ceramic PCB is often the preferred solution.

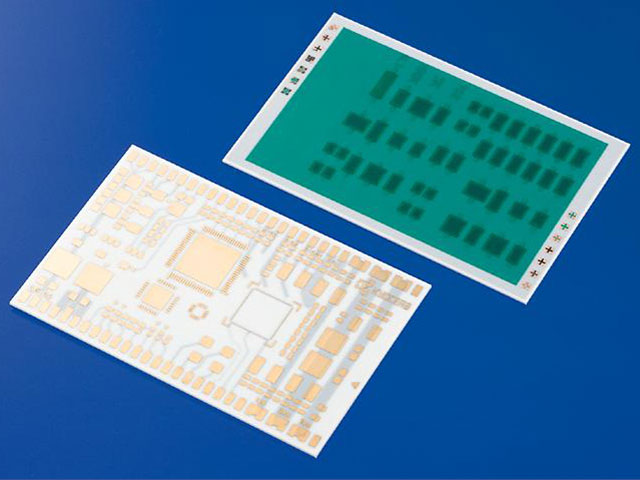

Ceramic PCB Manufacturing Technologies

Common Ceramic PCB manufacturing processes include:

-

Direct Bonded Copper (DBC) Ceramic PCB

-

Direct Plated Copper (DPC) Ceramic PCB

-

Thick Film Ceramic PCB

-

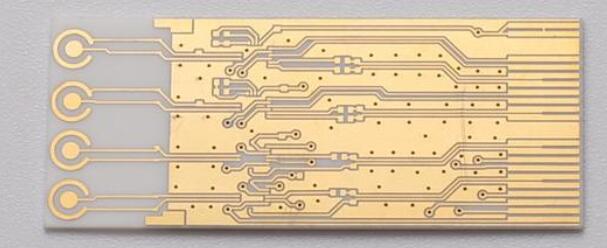

Thin Film Ceramic PCB

Each manufacturing method supports different:

-

Copper thickness

-

Line width capability

-

Thermal performance

-

High frequency performance

Precision Ceramic PCB manufacturing requires:

-

Advanced laser processing

-

High-temperature sintering

-

Fine line etching

-

Strict quality inspection

Applications of Ceramic PCB

Ceramic PCBs are widely used in:

-

LED lighting modules

-

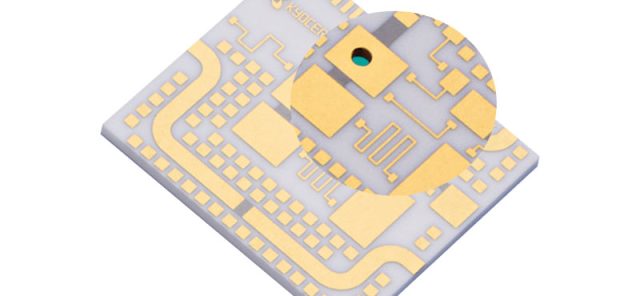

Power semiconductor modules (IGBT, MOSFET, SiC, GaN)

-

Automotive electronics and EV power systems

-

High power converters and inverters

-

RF and microwave modules

-

Aerospace and military electronics

-

Medical equipment

For SiC power modules and high current PCB applications, Ceramic PCB ensures superior heat management and reliability.

Ceramic PCB for High Power and High Current Applications

In high power designs, excessive heat can reduce reliability and lifespan. Ceramic PCB offers:

-

Direct heat transfer from components to substrate

-

Reduced thermal resistance

-

Enhanced mechanical stability

-

Improved power density

Ceramic PCB is ideal for:

-

High current PCB designs

-

High voltage PCB applications

-

Power amplifier modules

-

Electric vehicle power electronics

Ceramic PCB vs FR-4 PCB

| Feature | Ceramic PCB | FR-4 PCB |

|---|---|---|

| Thermal Conductivity | Very High | Low |

| Temperature Resistance | Excellent | Moderate |

| Mechanical Strength | High | Moderate |

| High Voltage Capability | Strong | Limited |

| Cost | Higher | Lower |

For high reliability and high temperature environments, Ceramic PCB significantly outperforms standard PCB materials.

Ceramic PCB Manufacturing Capabilities

Professional Ceramic PCB manufacturers typically offer:

-

DBC and DPC Ceramic PCB production

-

Multilayer Ceramic PCB

-

Thick copper Ceramic PCB

-

High precision fine line Ceramic PCB

-

High power module PCB fabrication

-

Custom Ceramic PCB prototype and mass production

Strict inspection and reliability testing ensure stable performance for demanding applications.

Choosing the Right Ceramic PCB Supplier

When selecting a Ceramic PCB supplier, consider:

-

Experience in power electronics PCB

-

Capability in DBC / DPC manufacturing

-

Thermal management expertise

-

Quality control and testing systems

-

Custom design support

-

Fast prototype and production capability

A reliable Ceramic PCB manufacturer ensures long-term stability, high thermal performance, and consistent quality.